Centralized feed production line

A centralized and production line technology, applied in the direction of feed, dry solid materials, chemical instruments and methods, etc., can solve the problems of safety hazards, raw material loss, time-consuming and labor-intensive problems, and achieve the effects of improved production efficiency, uniform moisture, and good fermentation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below.

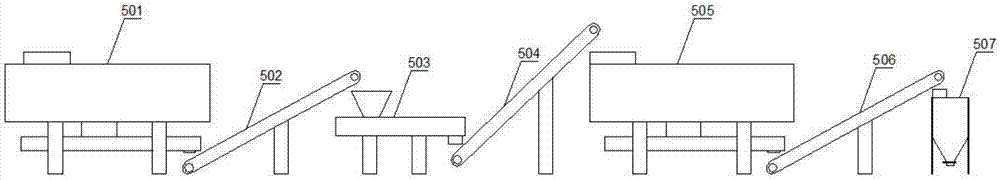

[0028] Such as Figure 1 to Figure 6 As shown, a centralized feed production line includes fermentation device 501, belt conveyor one 502, conditioning device 503, belt conveyor two 504, drying device 505, hoist 506 and stirring device arranged in sequence from left to right 507;

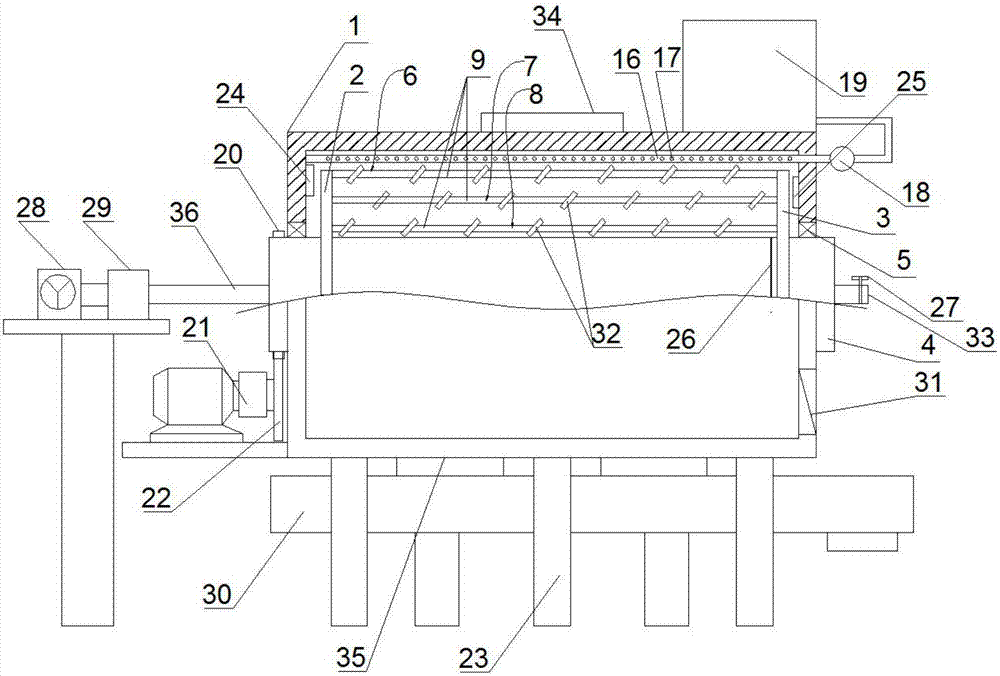

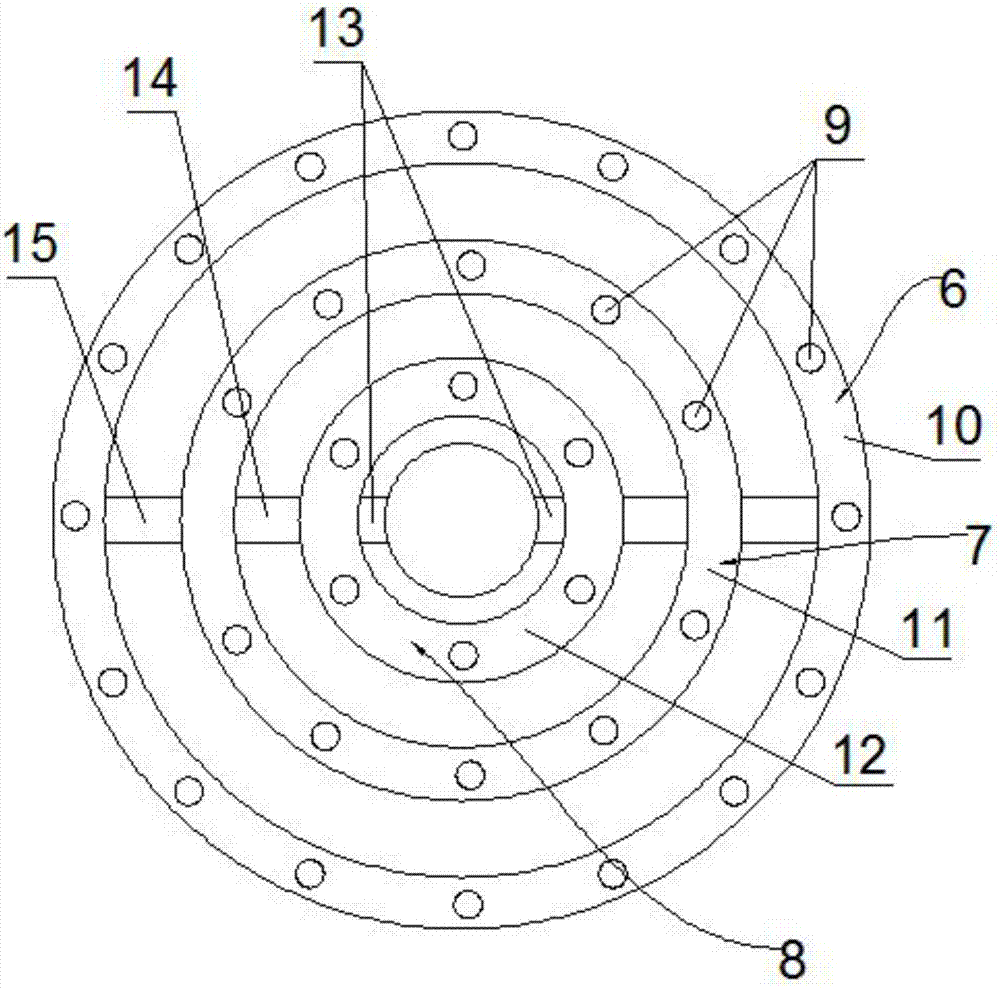

[0029] The fermentation device 501 includes a support cylinder 1, an air intake unit 2, an air outlet unit 3, and a screw conveyor 30. The support cylinder 1 is provided with a rotating cylinder 4 with a cavity inside. The rotating cylinder The left and right end plates of the body one 4 are correspondingly provided with two through holes, and the positions corresponding to the left and right parts of the rotating cylinder one 4 and the two through holes are respectively connected to the supporting cylinder through two bearings one 5 The left and right end plates of 1 are connected; the inside of the supporting cylinder 1 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com