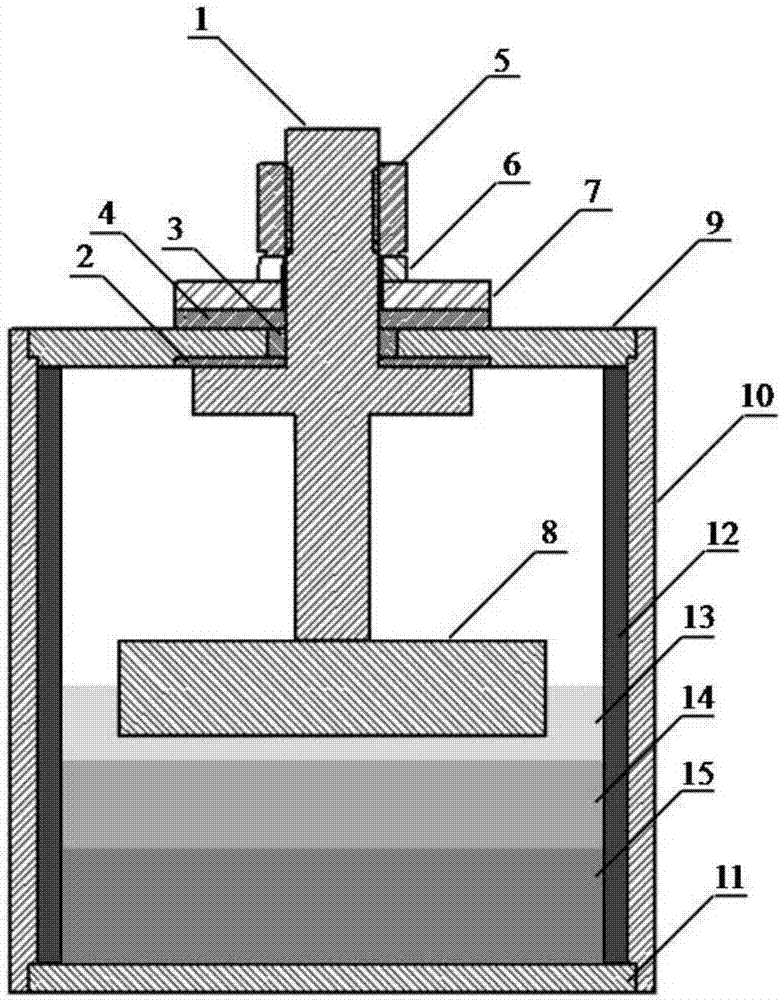

Compact liquid metal battery and assembly method thereof

A liquid metal battery, compact technology, used in secondary batteries, battery pack parts, battery boxes/jackets, etc., can solve the problems of high cost, low product yield, complex battery processing technology, etc., to prolong the service life , The effect of compressing the space volume and the battery assembly process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

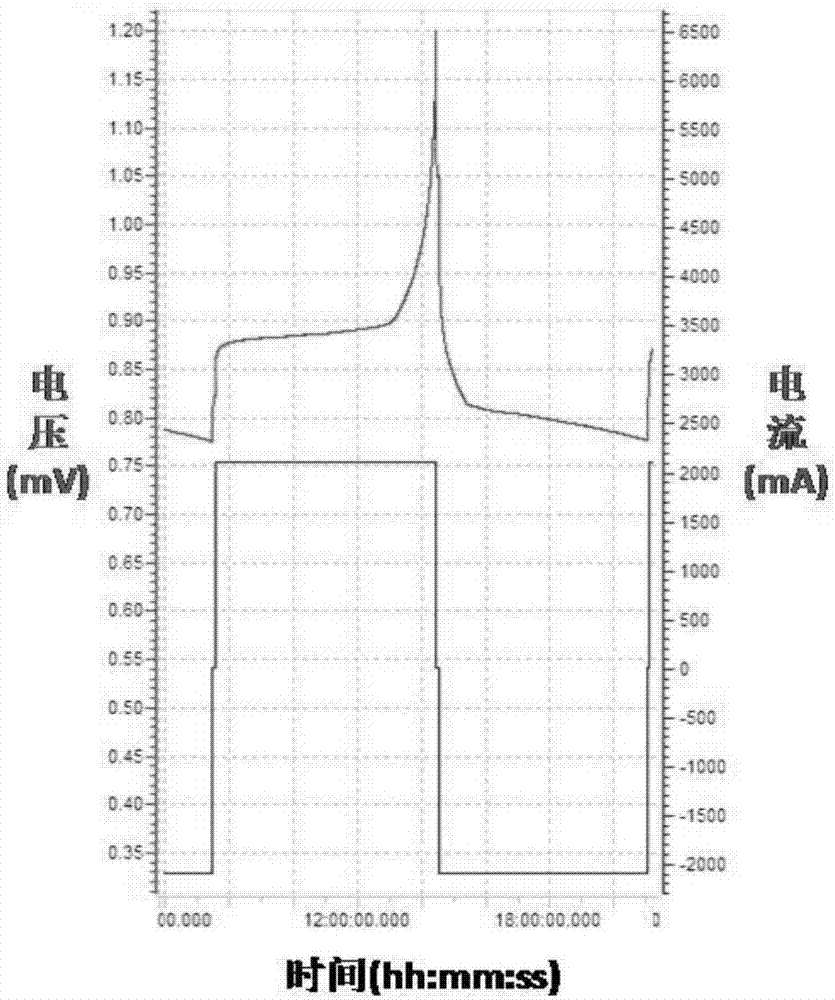

Examples

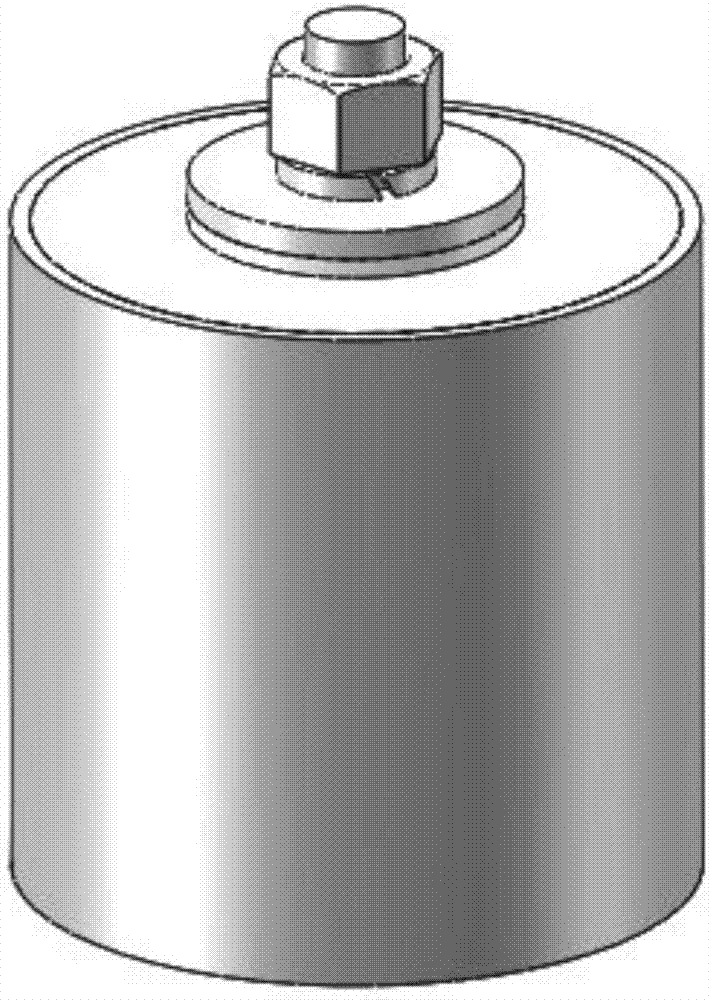

preparation example Construction

[0049] 1) Preparation of negative electrode material 13 . Put the negative electrode material 13 into a container, heat and melt it, wait for the negative electrode material 13 and the negative electrode current collector 8 to keep warm for a period of time and form good wetting, and then cool to room temperature. Specifically, the heating process is to raise the temperature to 300-800° C. at a rate of 1-5° C. / min, keep the temperature for 3-5 hours, and then cool down naturally to room temperature. When using the negative electrode current collector 8 of solid stainless steel round block, place the negative electrode current collector 8 in the negative electrode material 13 for soaking, stop heating after the negative electrode current collector 8 is fully wetted by the negative electrode material 13 and let it cool down to room temperature naturally. When the negative electrode current collector 8 of porous metal foam is used, the negative electrode current collector 8 is im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com