Iron-based nano amorphous magnetic core and application thereof

A nano-amorphous, iron-based technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low initial magnetic permeability, raw material selection or raw material ratio, etc., to improve the initial magnetic permeability, volt The output of safety characteristics is smooth and the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

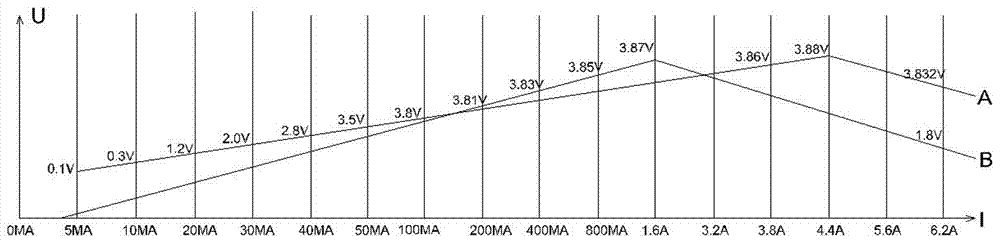

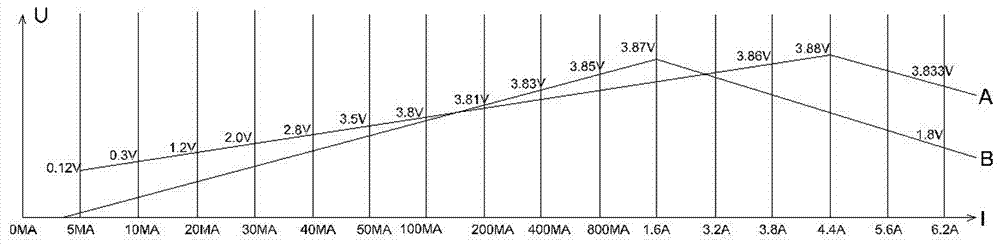

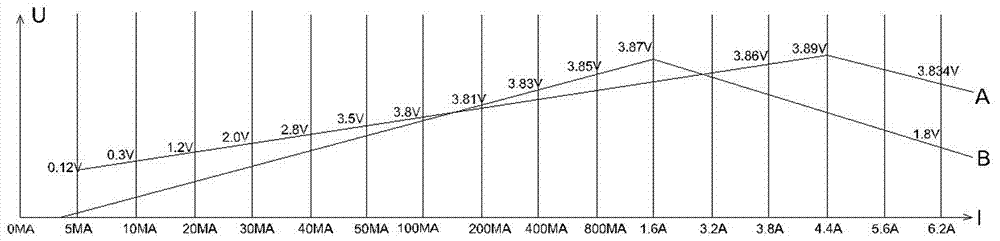

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of preparation method of iron-based nano-amorphous magnetic core, comprises the following steps:

[0028] Put Fe73 parts, Si10 parts, B13 parts, Cu1 parts and Nb3 parts into vacuum heat treatment furnace by weight and carry out heat treatment; heat treatment process comprises four stages:

[0029] The first stage: the temperature is raised from room temperature to 280°C at a constant speed for 60 minutes, and then the temperature is kept at

[0030] 280℃, keep warm for 60min;

[0031] The second stage: the temperature is raised from 280°C to 380°C at a uniform speed for 30 minutes, and then the temperature is kept at

[0032] 380°C, keep warm for 60min;

[0033] The third stage: the temperature is raised from 380°C to 480°C at a uniform speed for 30 minutes, and then the temperature is kept at

[0034] 480℃, keep warm for 60min;

[0035] The fourth stage: the temperature is raised from 480°C to 550°C at a uniform speed for 90 minutes, and then t...

Embodiment 2

[0037] The only difference between embodiment 2 and embodiment 1 is that the iron-based nano-amorphous core includes raw materials and their parts by weight: 73 parts of Fe, 10 parts of Si, 13 parts of B, 1 part of Cu and 0.8 parts of Mo.

Embodiment 3

[0038] The only difference between embodiment 3 and embodiment 1 is that the iron-based nano-amorphous magnetic core includes raw materials and parts by weight: 71 parts of Fe, 12 parts of Si, 13.5 parts of B, 1 part of Cu, 2.5 parts of Nb and 1 part of Cr.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com