Silicon melt temperature field reconstruction method based on free liquid level temperature measurement value and feature function interpolation

A characteristic function and temperature measurement technology, which is applied in the fields of self-melt liquid pulling method, chemical instruments and methods, special data processing applications, etc. The effect of extending the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

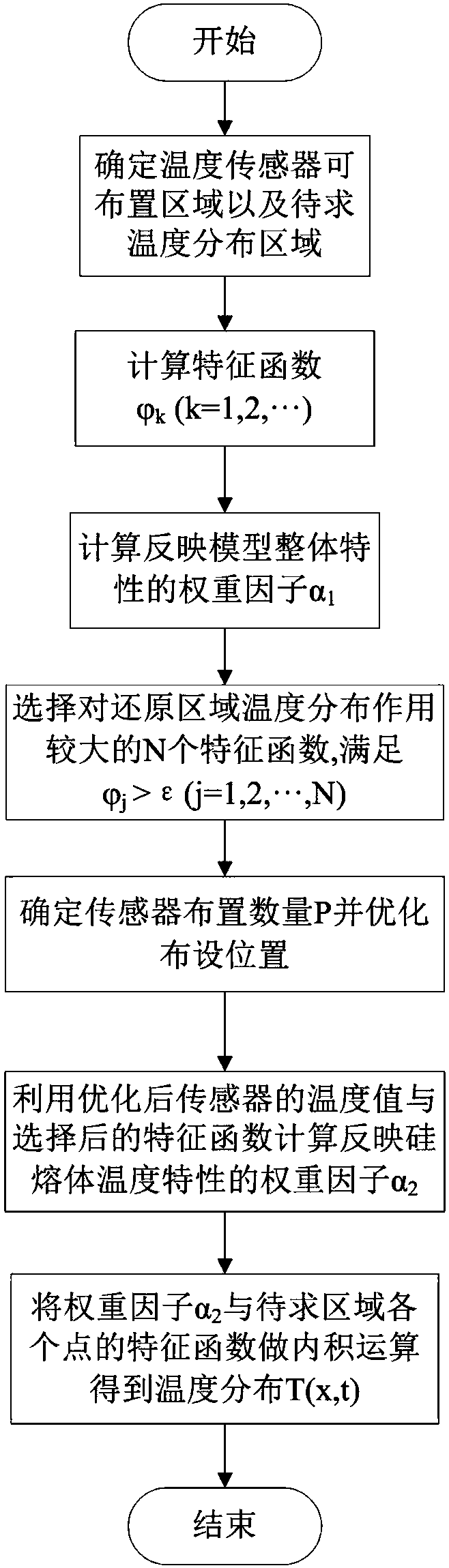

[0045] Such as figure 1 As shown, the silicon melt temperature field reconstruction method based on free liquid surface temperature measurement and characteristic function interpolation is implemented according to the following steps:

[0046] Step 1: Establish a two-dimensional axisymmetric silicon melt geometric model of the TDR-120 single crystal furnace; model the temperature field of the silicon melt in the isodiametric stage of the crystal growth process, and the free liquid surface is the area where temperature sensors can be arranged П, silicon The melt is the temperature field region Γ to be reconstructed. Using COMSOLMultiphysics software to calculate the thermal equation to obtain the temperature distribution in the silicon melt region Where x represents the coordinates of the inner point of the silicon melt; the results are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com