A quantum water processor and functional materials for water treatment

A functional material and water processor technology, applied in the field of water treatment, can solve the problems of high cost and uneven water purification capacity, and achieve the effects of long service life, space saving and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

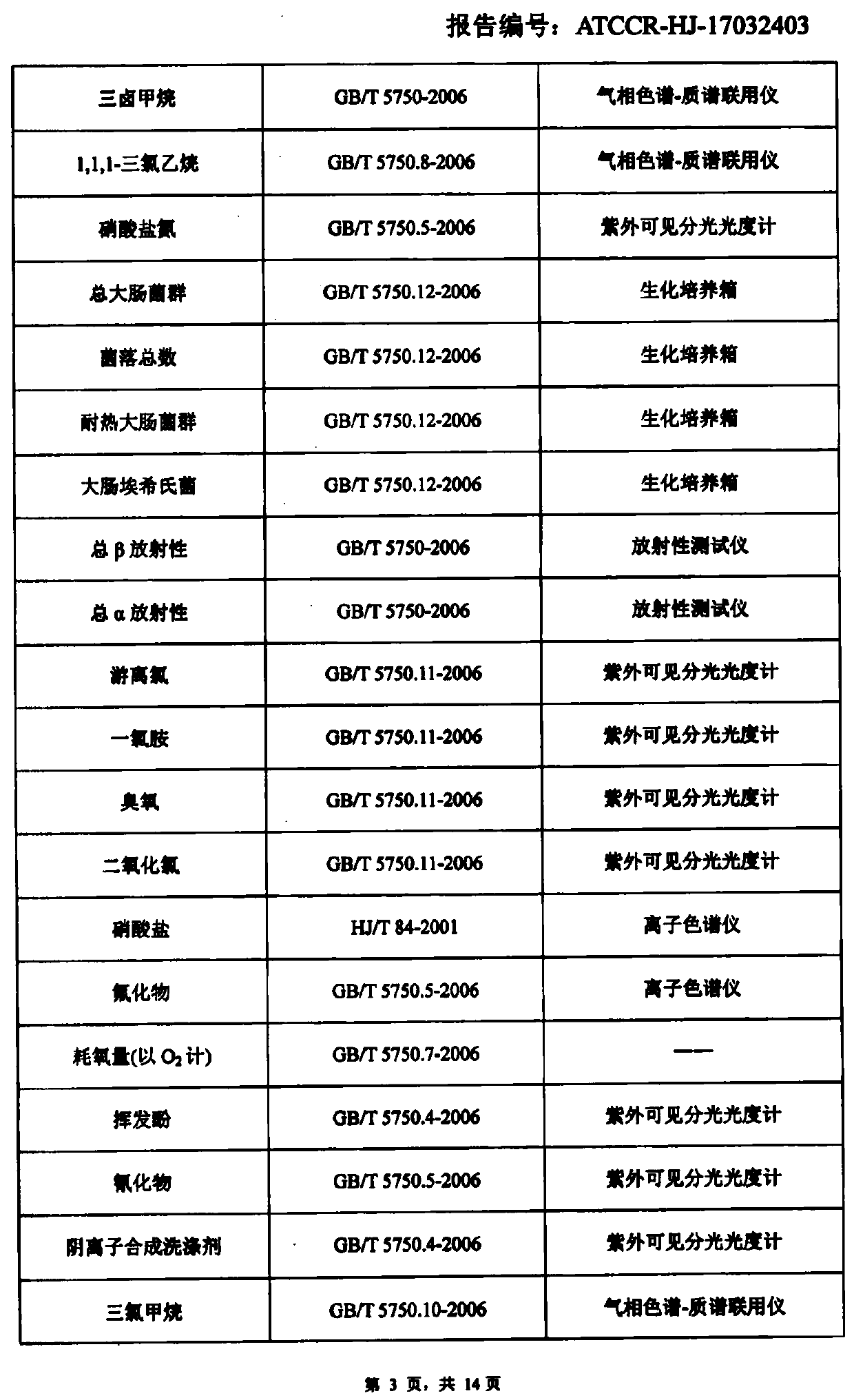

Image

Examples

Embodiment 1- Embodiment 6

[0020] A functional material for water treatment, the composition elements and mass percentages are shown in Table 1.

[0021] Table 1 Examples 1-6 are used for the constituent elements and mass percentages of functional materials for water treatment

[0022] Example 1 2 3 4 5 6 Ce 2.3 2.1 2.7 2.2 1.3 3.5 Pm 3.5 2.6 3.6 2.8 2.4 4.1 Co 7.2 6.5 7.5 7.0 5.7 8.9 Sc 3.1 3.1 4.2 3.5 2.5 4.5 Pr 4 3 4.1 3.5 2.7 4.5 La 2.2 2 2.3 2.1 1.8 2.5 Y 4.1 3.7 -- -- 7.9 5.1 Sm -- -- -- 4.1 -- 5.1 Nd 4.5 4.2 10 -- -- -- Fe margin margin margin margin margin margin

Embodiment 7

[0024] A functional material for water treatment, which is composed of the following elements by mass percentage: Ce 1.7%, Pm2.5%, Co 8.2%, Sc 4.1%, Pr 3.2%, La 1.9%, Sm 3.7%, Nd5 .6%, Fe 69.1%, the preparation method is as follows:

[0025] (1), carry out ingredients according to the chemical composition and mass percentage of the functional material for water treatment, place it in a vacuum intermediate frequency induction furnace, evacuate, and fill with argon for protection, the filling pressure is 0.05Mpa, and the other is The temperature of the molten alloy reaches 1580 °C to obtain a molten liquid alloy;

[0026] (2) The molten liquid alloy obtained in step (1) is placed in a vacuum heat treatment furnace, and after vacuuming, an inert gas is introduced. Functional materials for water treatment, in which the furnace cooling rate is 15°C / h.

Embodiment 8

[0028] A functional material for water treatment, which is composed of the following elements by mass percentage: Ce 2.5%, Pm 3.5%, Co 7.2%, Sc 4.5%, Pr 4.0%, La 1.9%, Y 4.6%, Sm 1.1%, Nd 5.1%, Fe 68%, the preparation method is as follows:

[0029] (1) Carry out ingredients according to the chemical composition and mass percentage of the functional material for water treatment, place it in a vacuum intermediate frequency induction furnace, evacuate, and fill with helium for protection, the filling pressure is 1.3Mpa, and the other is The temperature of the molten alloy reaches 1850 °C to obtain a molten liquid alloy;

[0030] (2) The molten liquid alloy obtained in step (1) is placed in a vacuum heat treatment furnace, and after vacuuming, an inert gas is introduced. Functional materials for water treatment, in which the furnace cooling rate is 25°C / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com