Liquid-phase discharge reactor for treatment of high-salinity organic wastewater

A technology of organic wastewater treatment and liquid phase discharge, which is applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., which can solve the problems of high conductivity discharge difficulties and improve operating efficiency , Improve the processing capacity, and the effect of liquid phase discharge uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

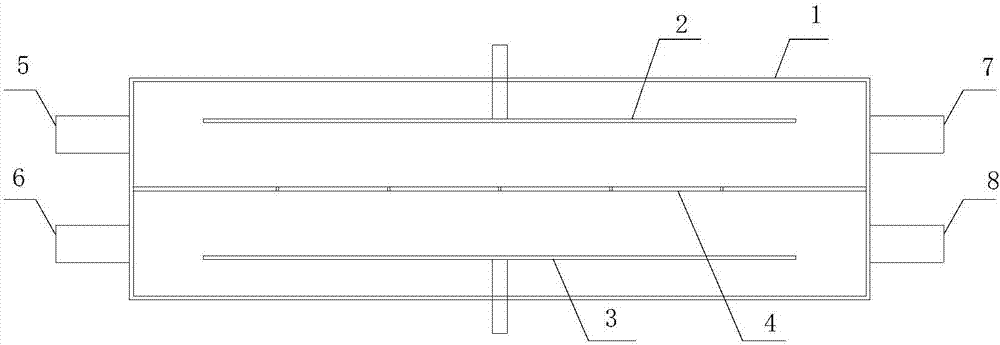

[0028] The invention provides a liquid-phase discharge reactor for the treatment of high-salt organic wastewater, such as figure 1 As shown, the reactor includes a reactor shell 1 , an electrode 2 connected to a high voltage plate, a ground electrode 3 and an insulating plate 4 with holes. The perforated insulating plate 4 is arranged inside the reactor shell 1 and divides the inside of the reactor shell 1 into two cavities. The electrode 2 connected to the high voltage plate and the ground electrode 3 are respectively arranged in two cavities. Each cavity is provided with a water inlet and a water outlet connected to the cavity. In this embodiment, an upper water inlet 5 , an upper water outlet 7 , a lower water inlet 6 and a lower water outlet 8 are provided. The reactor shell is an insulated closed container, which provides a reaction space for liquid phase discharge.

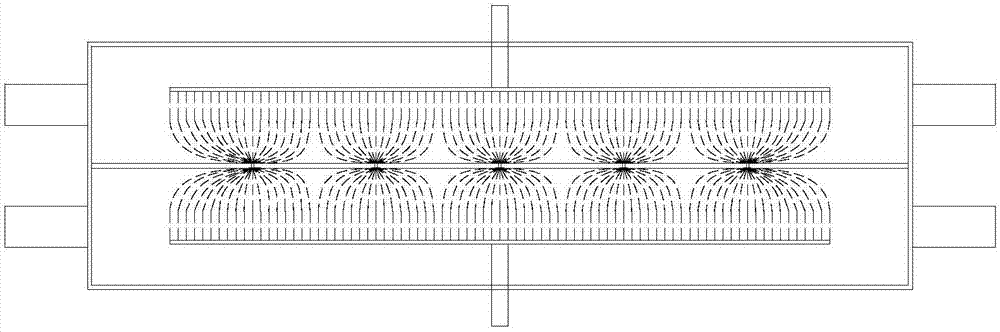

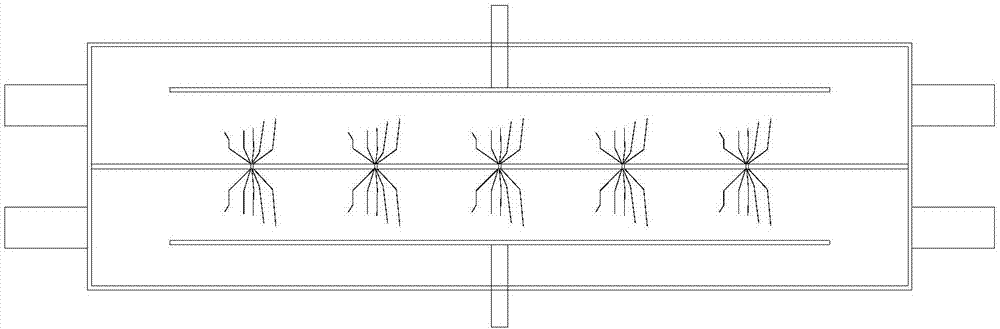

[0029] An electric field is formed between the two electrodes, and the distribution is shown in figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com