Framework type foldable combined material basket

A frame type and material basket technology, applied in the field of frame structure type material baskets, can solve the problems of inconvenient storage and turnover of idle material baskets, inconvenient storage and transportation of idle material baskets, and achieve the effect of convenient turnover transportation and saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A frame-type foldable composite basket of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

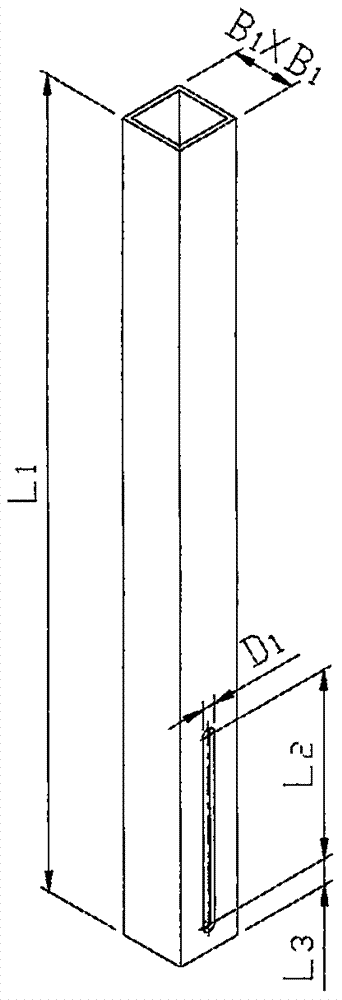

[0030] like figure 1 As shown, a frame-type foldable composite basket of the present invention mainly includes a base (1), a support leg (3), a limit plate I (2), a limit plate II (8), and a support sleeve (4) and support columns (6). The base (1) is welded by a Q235 square tube with a size of (50×50) mm, and the support legs (3) are welded under the base (1), and are used to limit the fork position of the forklift. 2) and the limit plate II (8) are welded to the side beam of the inner base (1) of the support leg (3), the distance between the limit plates is W=760mm, the thickness of the limit plate is 8mm, and the support sleeve (4) is welded to the base (1) Above, the reinforcing plate (7) used for strengthening is welded to the side beam of the inner base (1) of the support sleeve (4), the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com