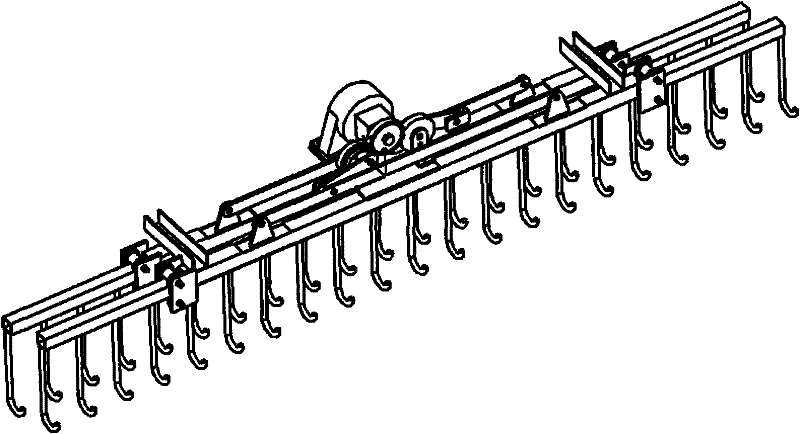

Special-purpose farm work rake for farm work machine in salt pan

A technology of live stubble machine and salt field, applied in the direction of alkali metal chloride, etc., can solve the problems of long rake body, unsatisfactory effect of live stubble operation, inconvenient driving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

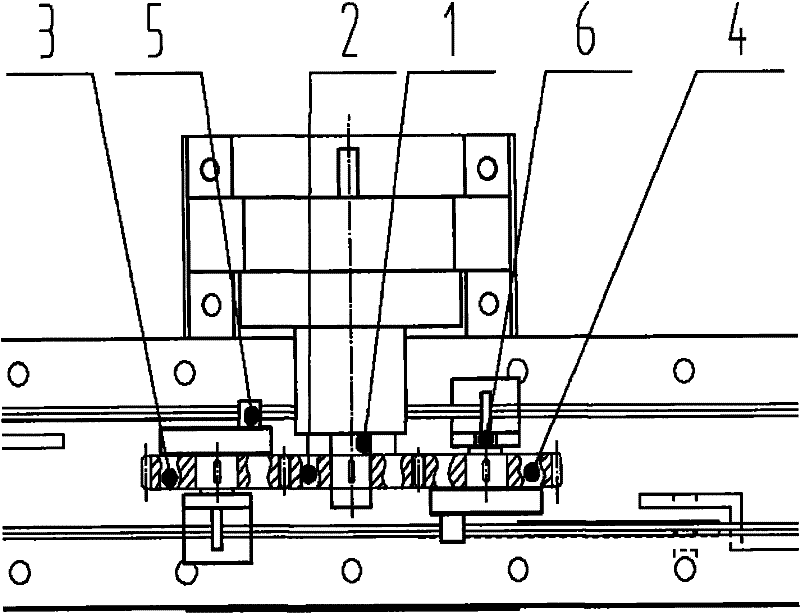

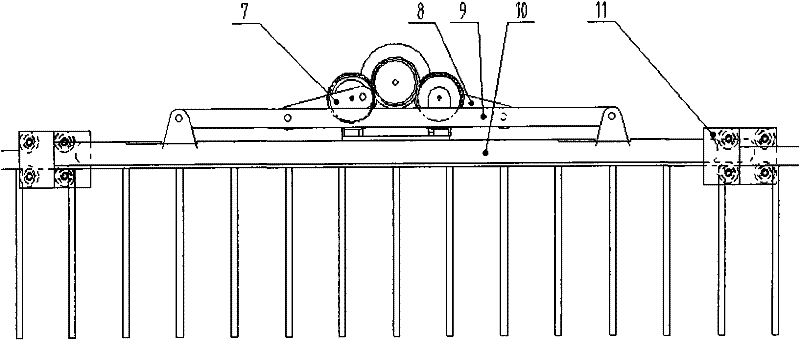

[0009] When the output power of the live stubble machine gearbox is transmitted to the main shaft (1), the main shaft (1) drives the driving wheel (2) to rotate, and the driving wheel (2) drives the driven wheel 1 (3) and the driven wheel 2 (4) to rotate, These two driven wheels respectively drive crank 1 (7) and crank 2 (8) through eccentric shaft 1 (5) and eccentric shaft 2 (6), and these two cranks drive the connected rake through their respective connecting rods (9) (10) Form left and right reciprocating motion on the rolling bearing (11) of vehicle frame body, finally reach the purpose of realizing the live stubble operation in Yantian.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com