Two-component sound-absorbing cotton with super sound absorbing effect

A two-component, sound-absorbing cotton technology, applied in the field of sound-absorbing materials, can solve problems such as poor shockproof and heat insulation effects, difficulty in recycling sound-absorbing cotton scraps, and sound-absorbing effects that cannot meet expectations, so as to increase the aesthetic feeling, Strong decoration and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

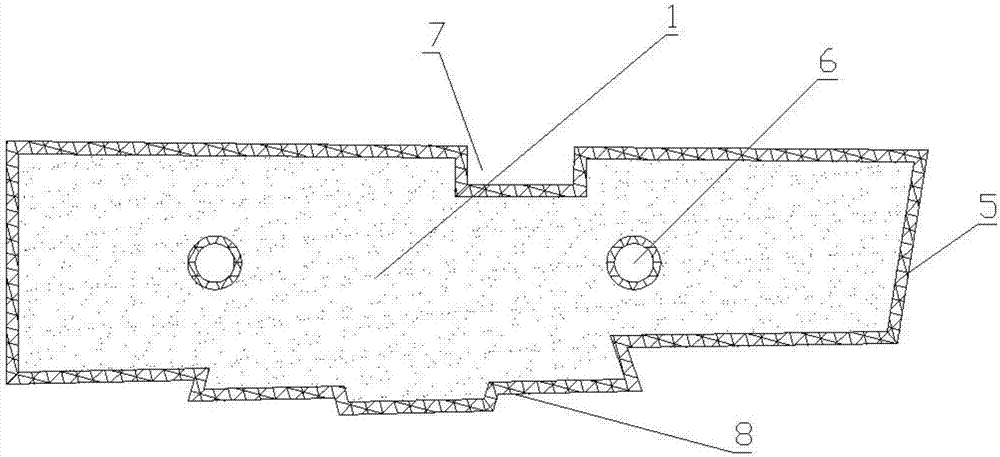

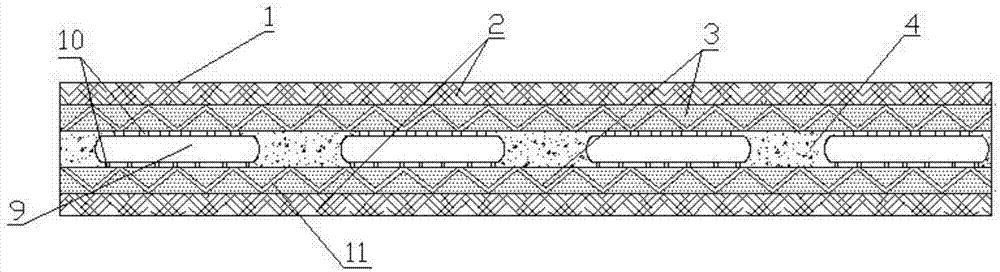

[0027] see Figure 1-2 As shown, the present invention provides a technical solution: a two-component sound-absorbing cotton with super sound-absorbing effect, the two-component sound-absorbing cotton includes a main cotton core 1, an outer layer 2, a middle surface layer 3, an inner surface layer 4, Double-sided edge banding 5, circular through hole 6, square groove 7, three-pointed protrusion platform 8, sound-absorbing cavity 9, sound-absorbing conduit 10 and V-shaped sound-absorbing hole 11, the edge of the main body cotton core 1 is fixed and designed as Double-sided edge banding 5, two symmetrical circular through-holes 6 are fixedly arranged on the main body cotton core 1, a square groove 7 is opened in the upper center of the main body cotton core 1, and the main body cotton core 1 The lower side middle part is fixedly designed with a three-pointed raised platform 8.

[0028] Further, the internal structure of the main body cotton core 1 is designed with 2 outer layer...

Embodiment 2

[0043] A new type of sound-absorbing cotton for the inner panel of the channel. The difference between this embodiment and Embodiment 1 is that the middle surface layer 3 is made of plant fibers evenly laid and pressed.

[0044] Plant stalks or leaves are squeezed and dried to obtain white plant fibers, which have the same excellent sound-absorbing function as the polylactate plastic fiber layer.

Embodiment 3

[0046]A new type of channel inner panel sound-absorbing cotton, the difference between this embodiment and embodiment 1 is that the middle surface layer 3 is made of silicon rubber foam plastic material.

[0047] The silicone rubber plastic is dissolved into a liquid at high temperature and then cooled rapidly by inert gas. The interior contains a bubble structure to obtain a silicone rubber foam. The silicone rubber foam has the same excellent sound-absorbing function as the polylactate plastic fiber layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com