A silicon core processing device

A technology for processing devices and silicon cores, applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of not meeting the requirements of silicon core processing, difficult to guarantee quality, affecting stable production, etc., to achieve convenient modification, Guarantee the effect of continuous processing and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

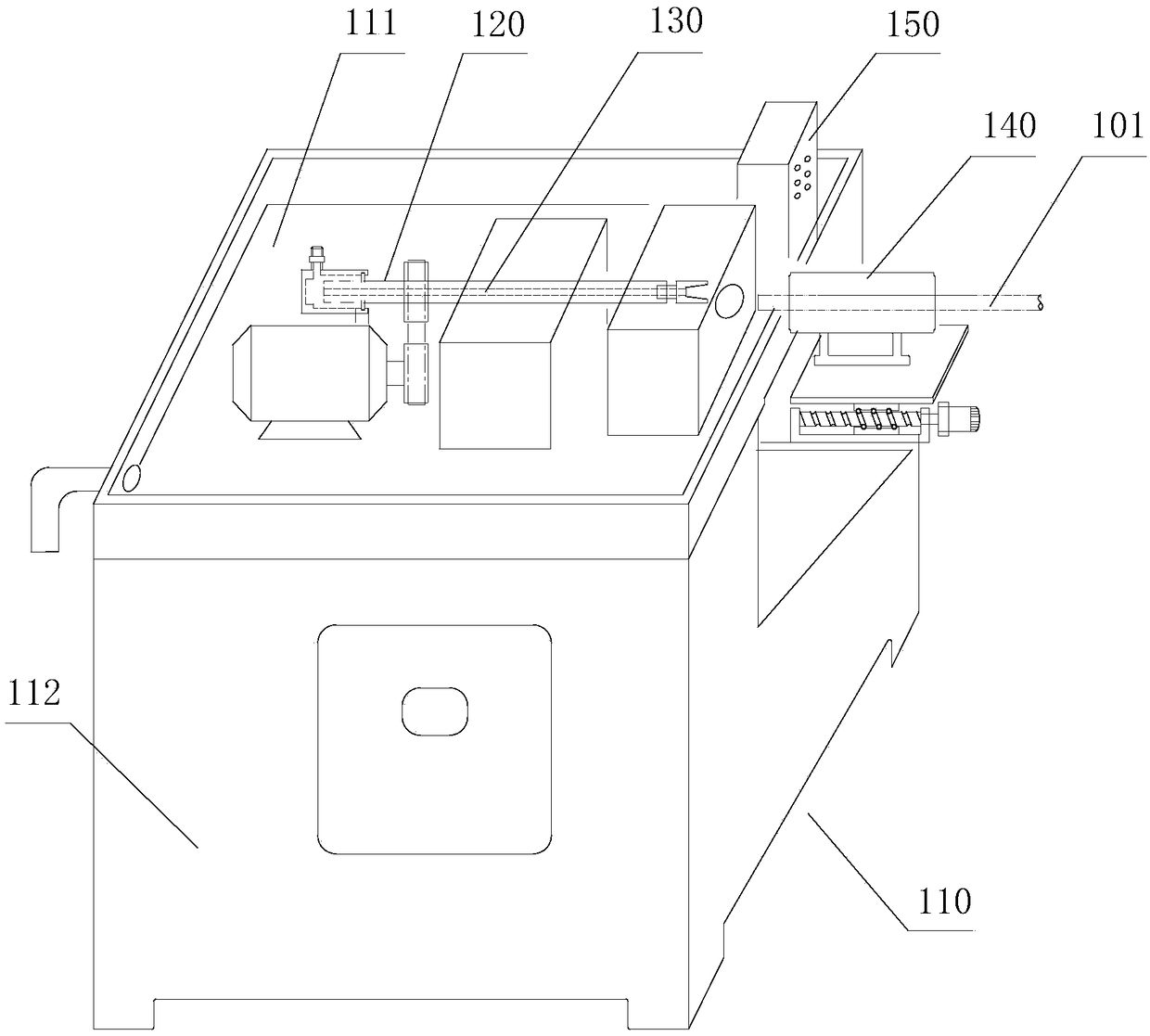

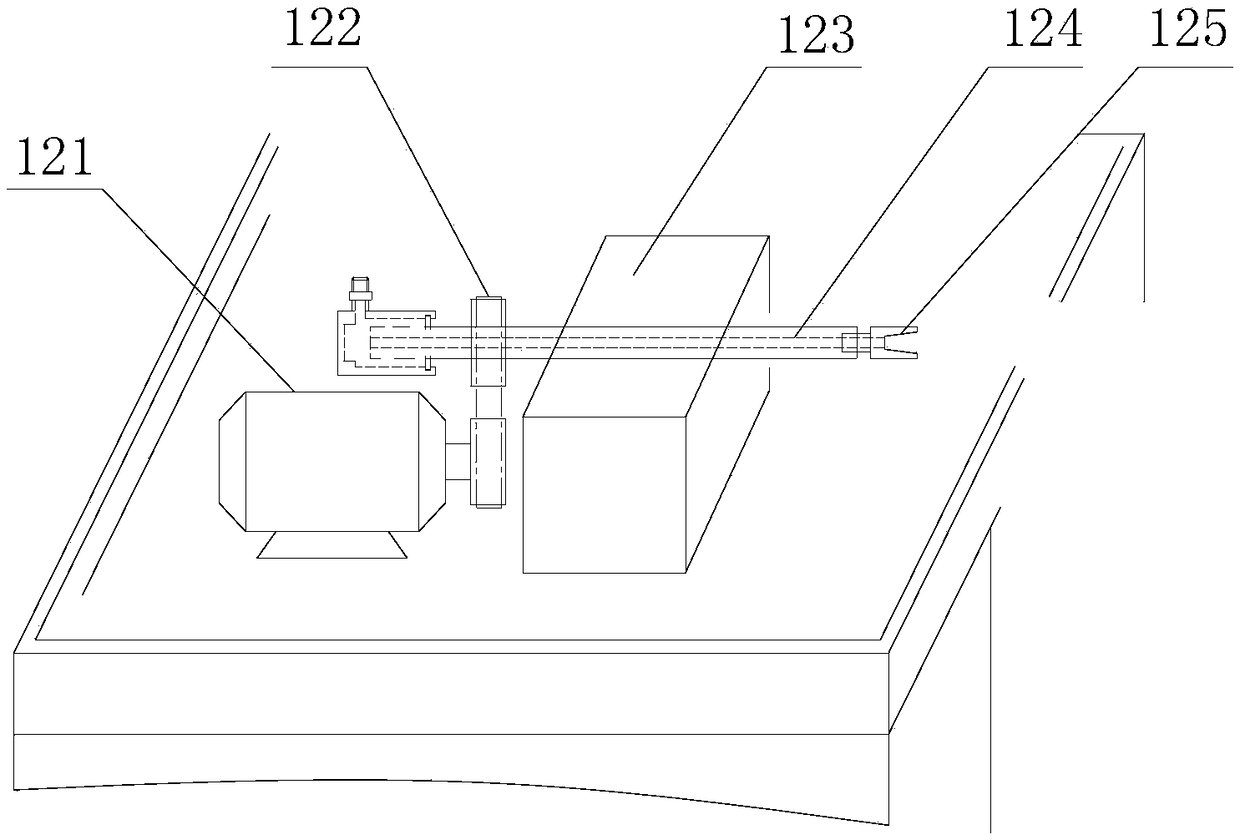

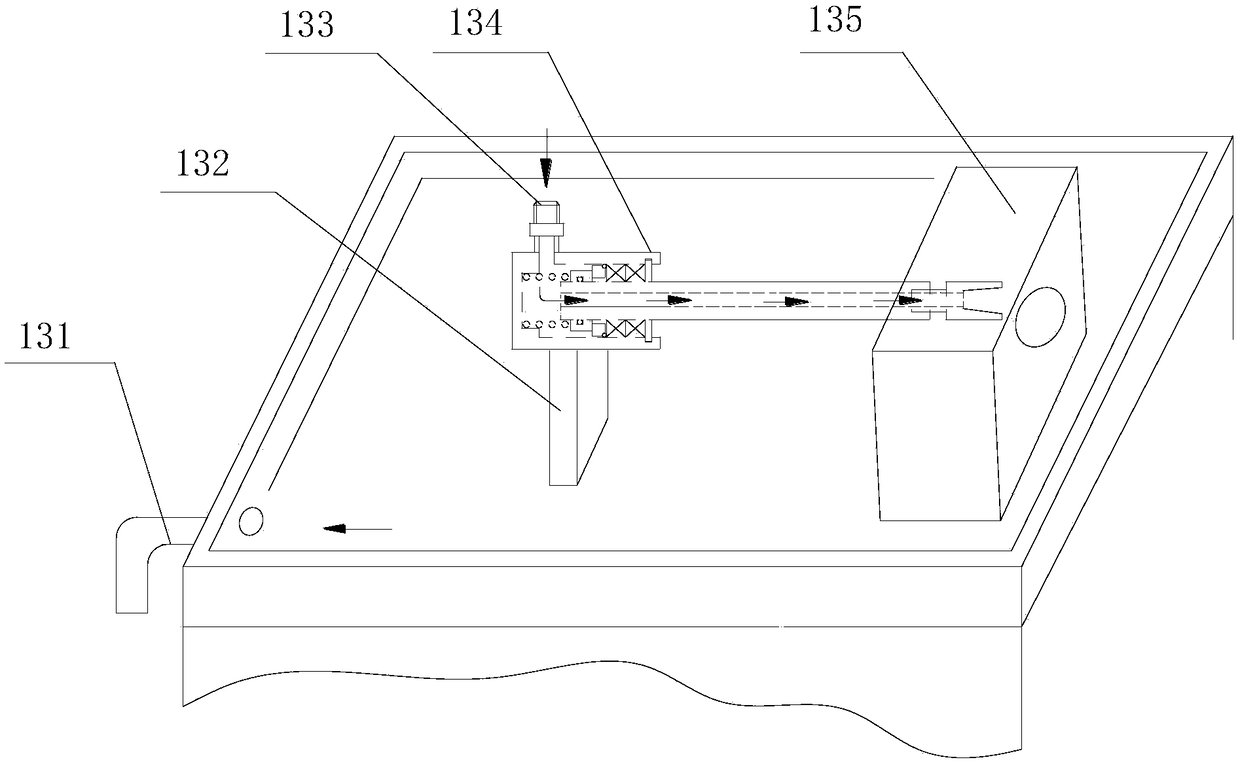

[0024] In this example, refer to Figure 1-Figure 6 , the silicon core processing device includes a box body 110, a spindle system 120, a cooling system 130, a positioning device 140 for fixing the silicon core 101, and a control system 150, the spindle system 120 is arranged on the box body 110, and the spindle system 120 is connected to the The control system 150 is connected, and the movement of the main shaft 124 is controlled by the control system 150; the water supply mechanism 133 of the cooling system 130 is set in the main shaft system 120, and the water return mechanism 131 is attached to the box body 110; the positioning device 140 is set on the side of the box body 110, positioning The device 140 is connected with the control system 150, and the silicon core 101 is installed on the positioning device 140. When the silicon core 101 is processed, the control system 150 controls the positioning device 140 to act according to the programmed stored program to complete th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com