A composite vibrating mixer capable of classifying raw materials

A technology of grading treatment and compound vibration, applied in grading, cement mixing device, raw material supply device for sale, etc., can solve the problems of delaying the mixing time of the whole machine, fine powder sticking to the shaft, low mixing speed, etc., to enhance the microscopic uniformity , The effect of improving the performance of vibration compaction and reducing the amount of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

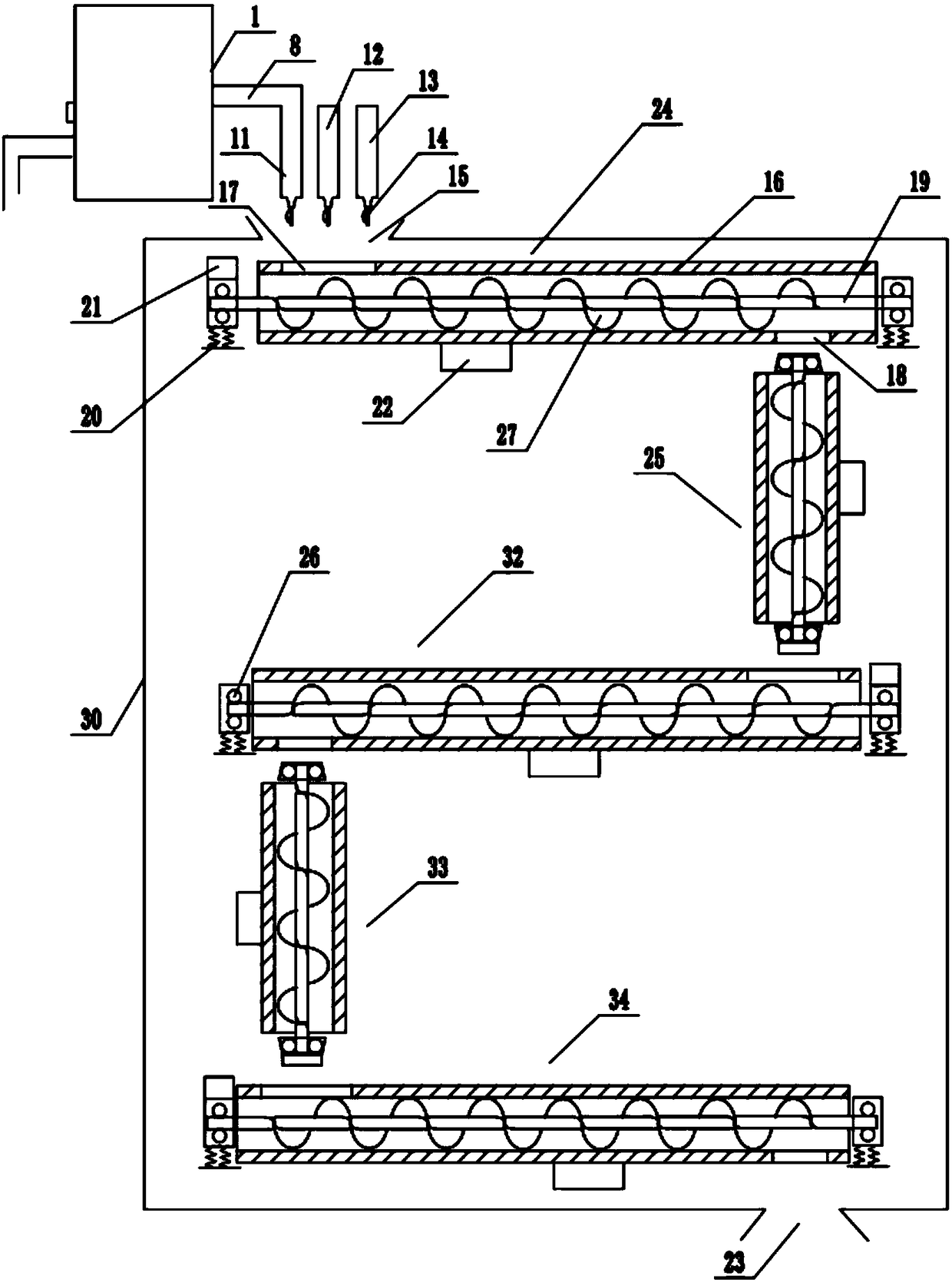

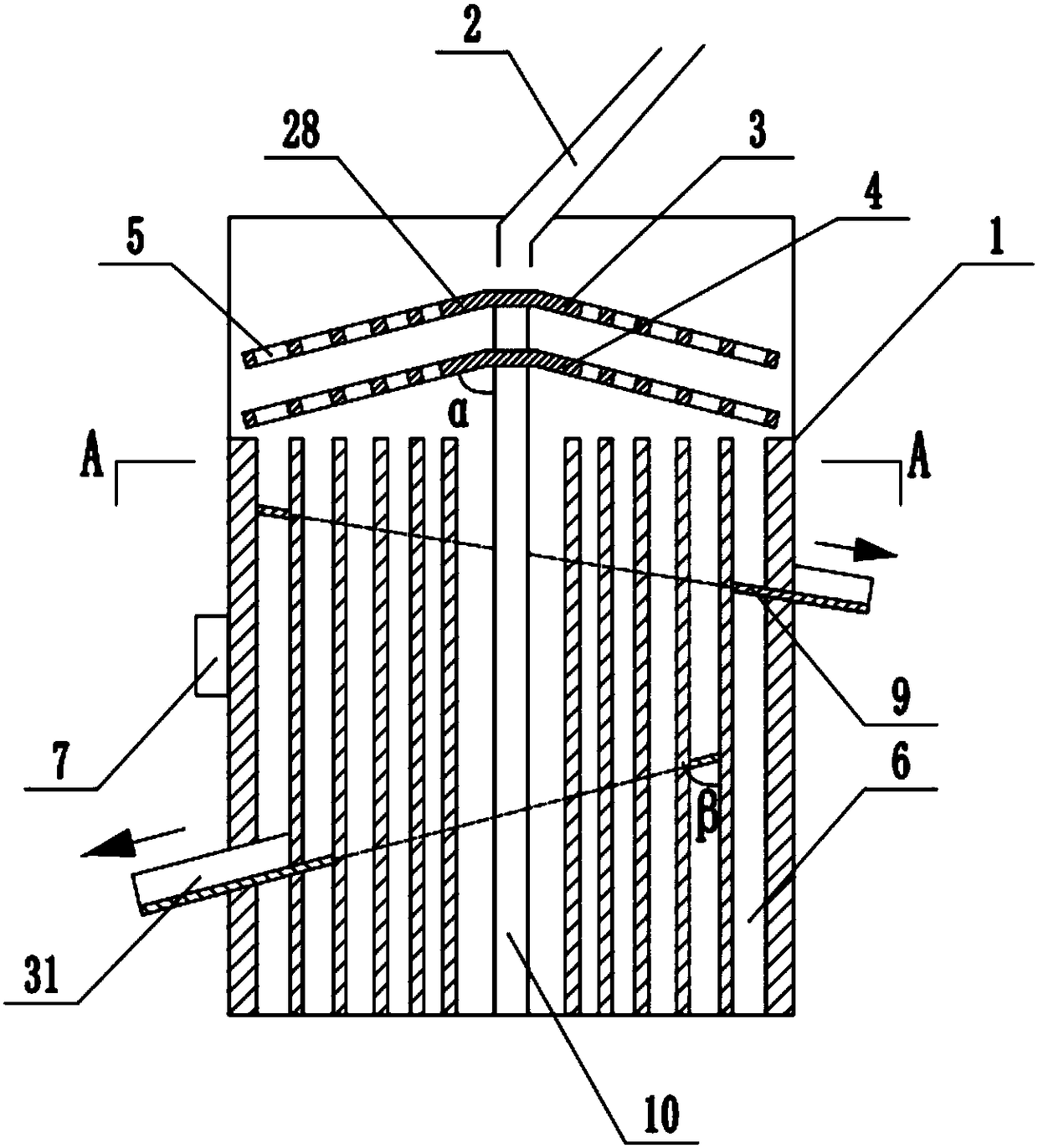

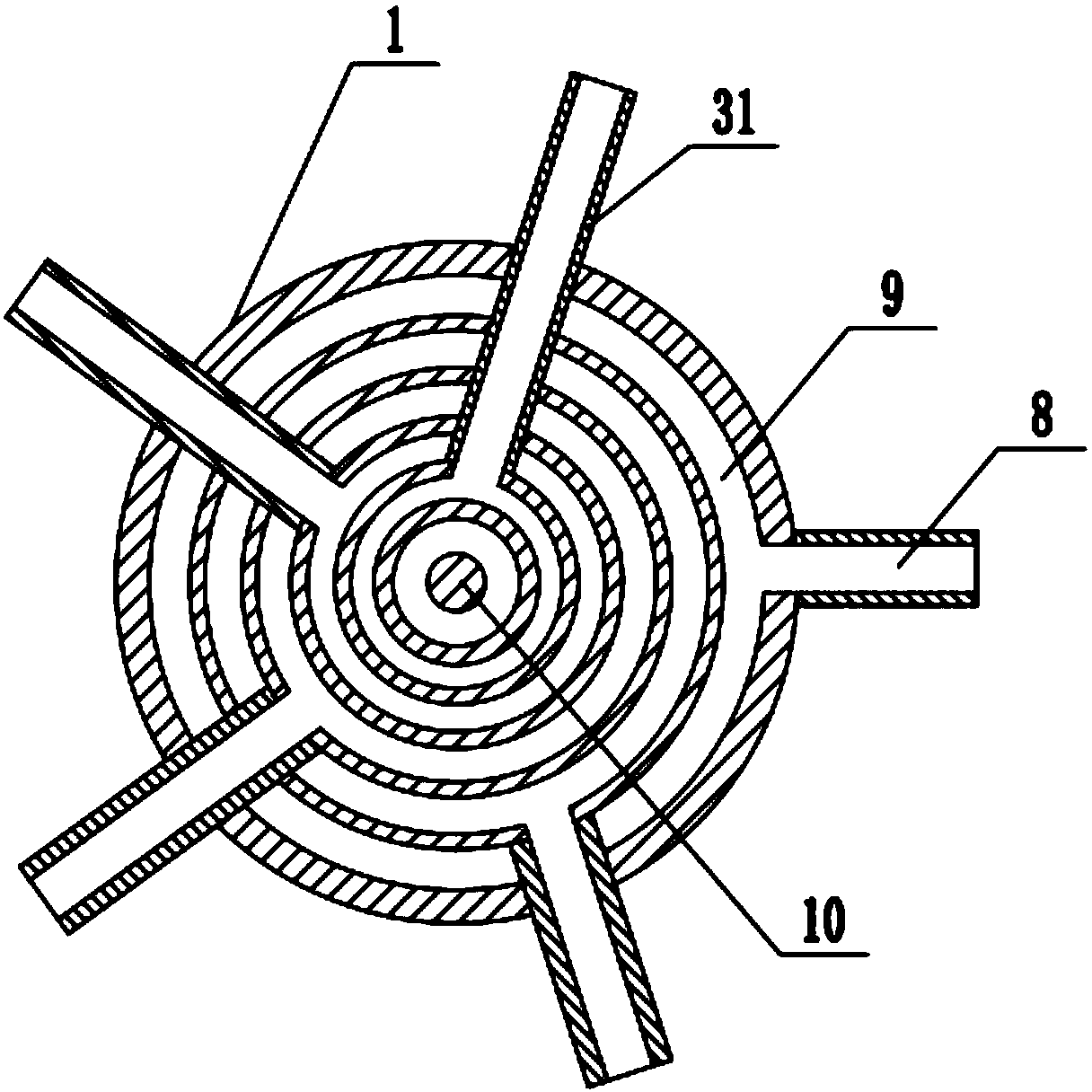

[0023] See attached figure 1 , 2 , the present invention includes a grading part and a stirring part, the grading part includes a grading cylinder wall 1, a first rotary table 3 and a rotating shaft 10, and the first rotating table 3 and the rotating shaft 10 are arranged in the grading cylinder wall 1, so The top of the classification cylinder wall 1 is provided with a stone inlet 2, and the blanking place of the stone inlet 2 is arranged at the center of the first rotary table 3, and the second rotary table 4 is arranged at the bottom of the first rotary table 3, and the first rotary table 3 and the second rotary table 3 are connected to each other. The two rotating tables 4 are jointly arranged on the rotating shaft 10, and the rotating shaft 10 drives the first rotating table 3 and the second rotating table 4 to rotate together, and the rotating panels 28 of the first rotating table 3 and the second rotating table 4 are provided with leakage holes 5, Leak holes 5 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com