Polishing brush for curved surface board and plane board

A grinding brush and plane technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of labor waste, unfavorable handling, high cost, reduce the use cost, avoid excessive grinding, and facilitate transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

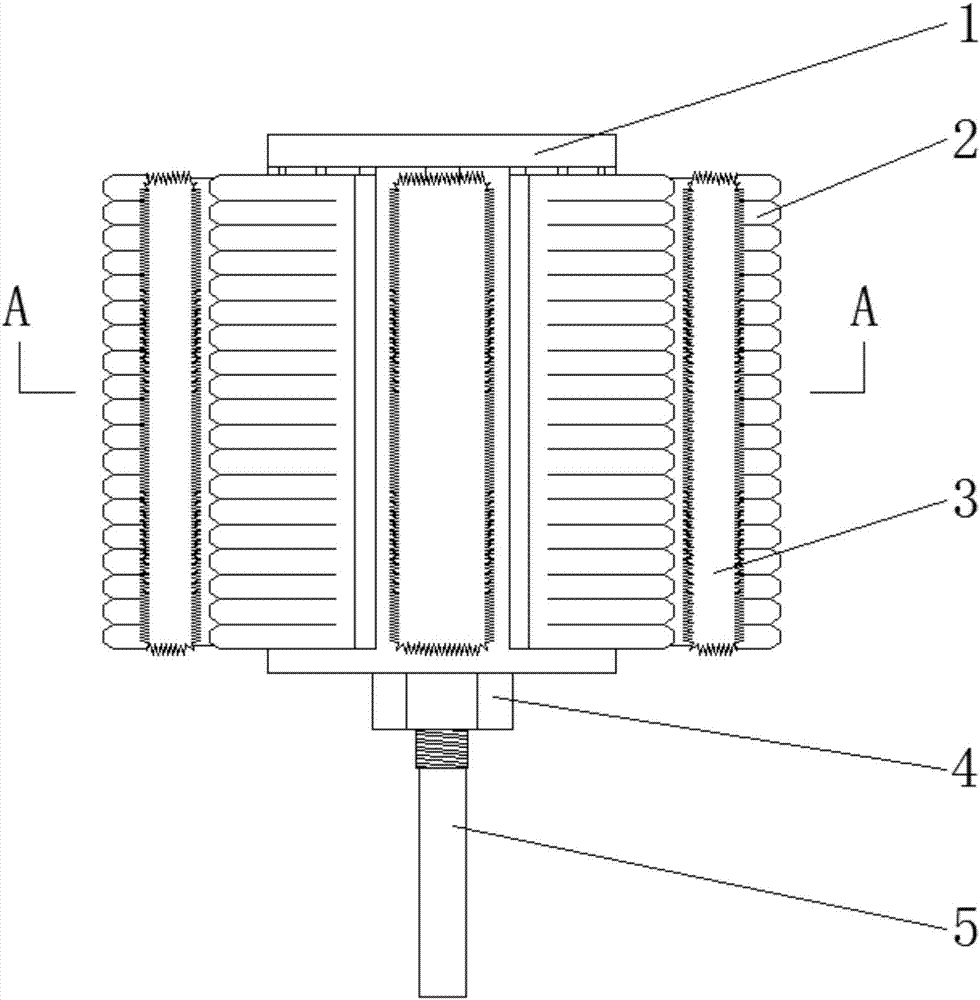

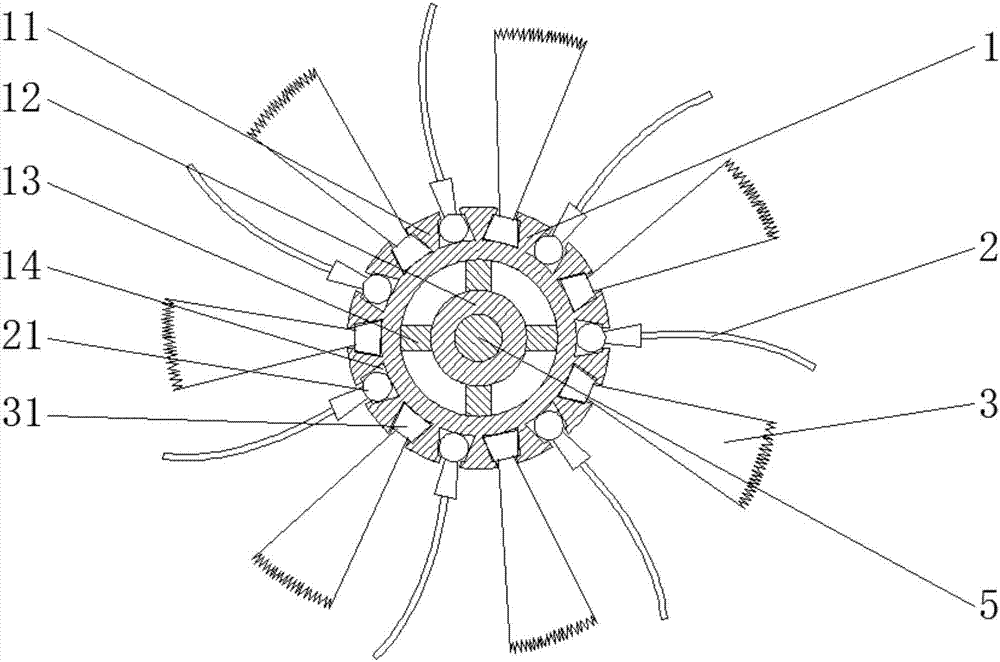

[0030] Such as Figure 1-4 As shown, the present invention discloses a curved surface and planar wood polishing brush, comprising a drum 1, a sanding cloth 2, a brush bar 3, a nut 4, and a screw 5, and one side of the sanding cloth 2 is connected to the outer wall of the rotating drum 1 , the connecting edge of the abrasive cloth 2 and the drum 1 is parallel to the axis of the drum 1; the bottom edge of the brush bar 3 is connected with the outer wall of the drum 1, and the bottom edge of the brush bar 3 is parallel to the axis of the drum 1; the abrasive cloth 2 Alternately arranged with the brush strips 3; the screw 5 runs through the central axis of the drum 1, the nut 4 is mounted on the screw 5, and the drum 1 is compressed between the nut 4 and the head of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com