Soybean milk maker control method

A control method and technology of soymilk machines, which are applied in the control field of soymilk machines, can solve problems affecting the safety of the whole machine, rising machine temperature, hidden safety hazards, etc., so as to avoid a sharp rise in the temperature rise of the whole machine, reduce heat, and ensure production efficiency. The effect of slurry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

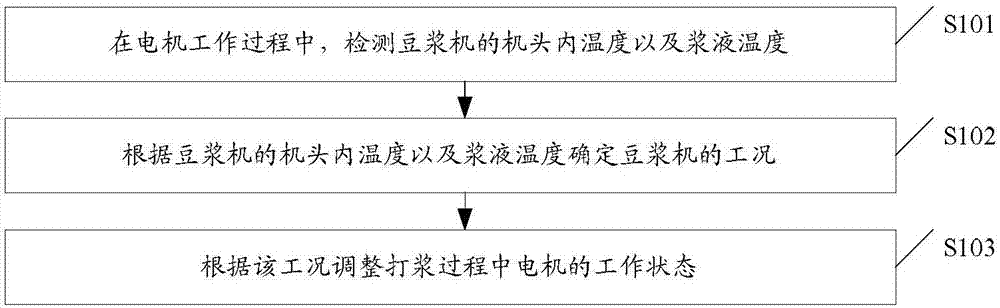

[0056] A control method for a soybean milk machine, such as figure 1 As shown, the method may include S101-S103:

[0057] S101. During the working process of the motor, detect the temperature inside the head of the soybean milk machine and the slurry temperature.

[0058] In the embodiment of the present invention, a thermistor can be pre-set in the upper space of the head of the soymilk machine to detect the temperature rise of the whole machine in the head (that is, the temperature inside the head of the soymilk machine), and a temperature sensor can be set at the lower part of the head. To check the slurry temperature. Set the temperature sensor at the lower part of the machine head as RT1, and the measured temperature is Tc1; the thermistor at the upper part of the machine head is RT2, and the measured temperature is Tc2; RT1 mainly detects the slurry temperature, and RT2 mainly detects the temperature inside the machine head.

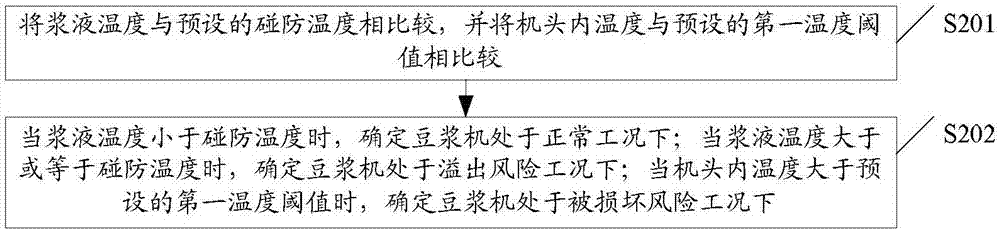

[0059] S102. Determine the working conditi...

Embodiment 2

[0085] The difference between this embodiment and the first embodiment is that the working condition of the soymilk maker is determined by the rate of temperature change, thereby limiting the working mode of the soymilk maker, so as to prevent the risk of overflow and the risk of failure of electronic components.

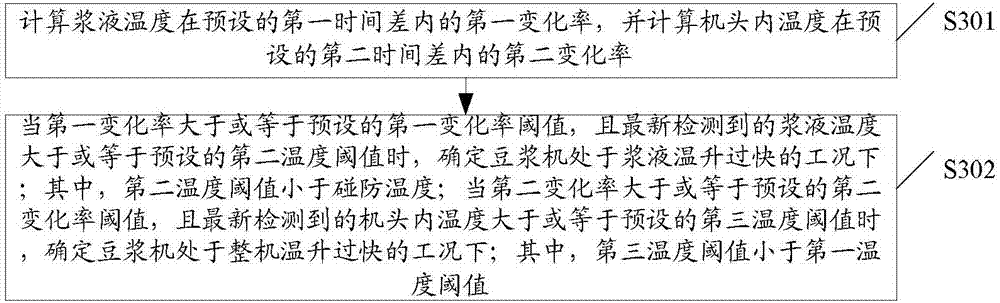

[0086] Optionally, as in image 3 As shown, determining the working conditions of the soymilk maker according to the temperature inside the head of the soymilk maker and the slurry temperature may also include S301-S302:

[0087] S301. Calculate the first change rate of the slurry temperature within the preset first time difference, and calculate the second change rate of the temperature in the head within the preset second time difference;

[0088] S302. When the first change rate is greater than or equal to the preset first change rate threshold and the latest detected slurry temperature is greater than or equal to the preset second temperature threshold, determin...

Embodiment 3

[0102] On the basis of Examples 1 and 2, this example provides a scheme for cooling down the temperature of the soymilk machine before beating.

[0103] Optionally, the method also includes:

[0104] If the temperature in the machine head is greater than or equal to the preset fourth temperature threshold before beating, then increase the waiting time before starting beating until the temperature in the machine head is less than or equal to the preset fifth temperature threshold, according to the preset The beating process starts beating; wherein, the fifth temperature threshold is smaller than the fourth temperature threshold.

[0105] In the embodiment of the present invention, the fourth temperature threshold and the fifth temperature threshold can be defined according to different application scenarios, and the specific values thereof are not limited. The fourth temperature threshold may include: 65°C-75°C, for example 70°C; the fifth temperature threshold may include: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com