Preparation method of pork chop

A technology for pork chops and pork chops, which is applied in the functions of food ingredients, food preservation, egg preservation, etc., can solve problems such as time-consuming, human health hazards, and aging of meat quality, so as to prevent changes in meat quality, reduce blood pressure, and reduce blood pressure. The effect of tenderizing pork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

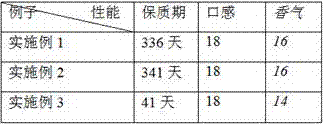

Embodiment 1

[0025] 1) Raw material trimming: Trim the unpacked frozen pork steak with a bone sawing machine, the thickness of the trimmed bone is 12-14 mm, and try to control each pork steak to be complete and uniform in thickness;

[0026] 2) Low temperature thawing: put the trimmed pork chops in the thawing solution, thaw until the meat center temperature is 1-5°C, take out and drain; the composition of the thawing solution is: 0.5wt% NaCl, 15wt% ginger juice , the balance is water;

[0027] 3) Vacuum tumbling: Add the drained pork ribs and compound seasonings into the tumbler for tumbling; the tumbling time is 1 hour, the temperature of the tumbling chamber is below 10°C, and the temperature of the product is 15°C. Below ℃; add the following compound seasonings for every 100kg pork steak: 60g green tea juice, 150g fungus juice, 50g Chinese toon juice, 200g water chestnut extract, 300g edible salt, 1000g monosodium glutamate, 500g shrimp paste, 1100g shrimp juice, 1kg soybean protein, ...

Embodiment 2

[0031] 1) Raw material trimming: Trim the unpacked frozen pork steak with a bone sawing machine, the thickness of the trimmed bone is 12-14 mm, and try to control each pork steak to be complete and uniform in thickness;

[0032] 2) Low-temperature thawing: put the trimmed pork chops in the thawing solution, thaw until the meat center temperature is 1-5°C, take out and drain; the composition of the thawing solution is: 0.8wt% NaCl, 13wt% ginger juice , the balance is water;

[0033] 3) Vacuum tumbling: Add the drained pork ribs and compound seasonings into the tumbler for tumbling; the tumbling time is 1 hour, the temperature of the tumbling chamber is below 10°C, and the temperature of the product is 15°C. Below ℃; add the following compound seasonings for every 100kg pork steak: 70g green tea juice, 110g fungus juice, 65g Chinese toon juice, 150g water chestnut extract, 350g edible salt, 700g monosodium glutamate, 550g shrimp paste, 950g shrimp juice, 2kg soybean protein, Mo...

Embodiment 3

[0037] 1) Raw material trimming: Trim the unpacked frozen pork steak with a bone sawing machine, the thickness of the trimmed bone is 12-14 mm, and try to control each pork steak to be complete and uniform in thickness;

[0038] 2) Low-temperature thawing: put the trimmed pork chops in the thawing solution, thaw until the meat center temperature is 1-5°C, take out and drain; the composition of the thawing solution is: 1.0wt% NaCl, 10wt% ginger juice , the balance is water;

[0039] 3) Vacuum tumbling: Add the drained pork ribs and compound seasonings into the tumbler for tumbling; the tumbling time is 1 hour, the temperature of the tumbling chamber is below 10°C, and the temperature of the product is 15°C. Below ℃; add the following compound seasonings for every 100kg pork steak: 80g green tea juice, 80g fungus juice, 80g Chinese toon juice, 100g water chestnut extract, 400g edible salt, 450g monosodium glutamate, 600g shrimp paste, 800g shrimp juice, 3kg soybean protein, Mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com