Closed rectangular-section FRP stirrup and manufacturing method thereof

A technology with a rectangular cross-section and a manufacturing method, which is applied to structural elements, building components, building reinforcements, etc., can solve problems such as bond-slip damage and low strength of the bending section of FRP stirrups, and achieve stress concentration relief and superior restraint , the effect of avoiding the corrosion of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

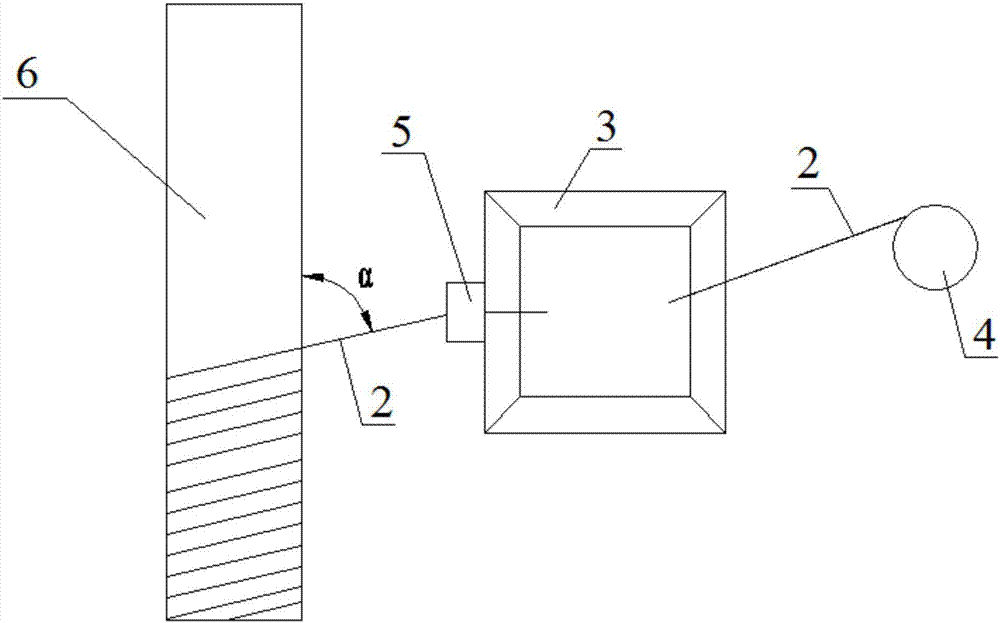

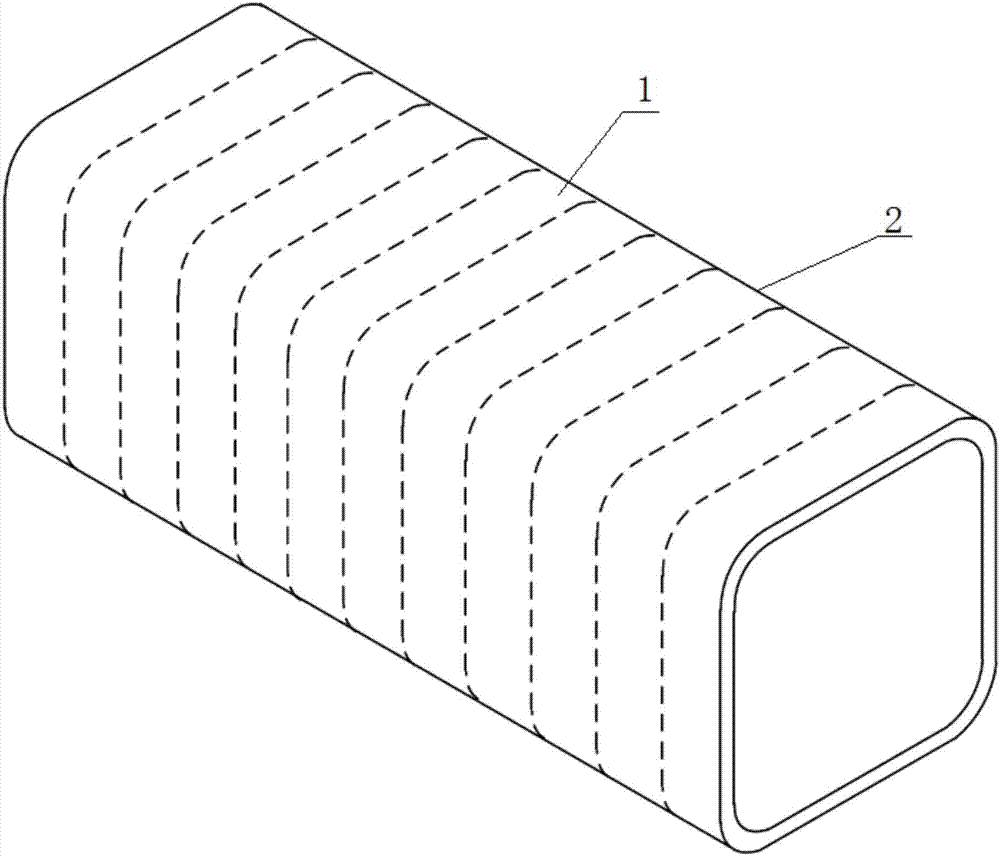

[0034] Specific implementation mode one: combine Figure 3 to Figure 11 To illustrate this embodiment, a closed rectangular cross-section FRP stirrup described in this embodiment includes a stirrup body 1, and the stirrup body 1 is formed by winding FRP bundles 2 impregnated with resin layer by layer along the circumferential direction of the stirrup. The cross-sectional shape of the body 1 along the direction perpendicular to the perimeter is rectangular.

specific Embodiment approach 2

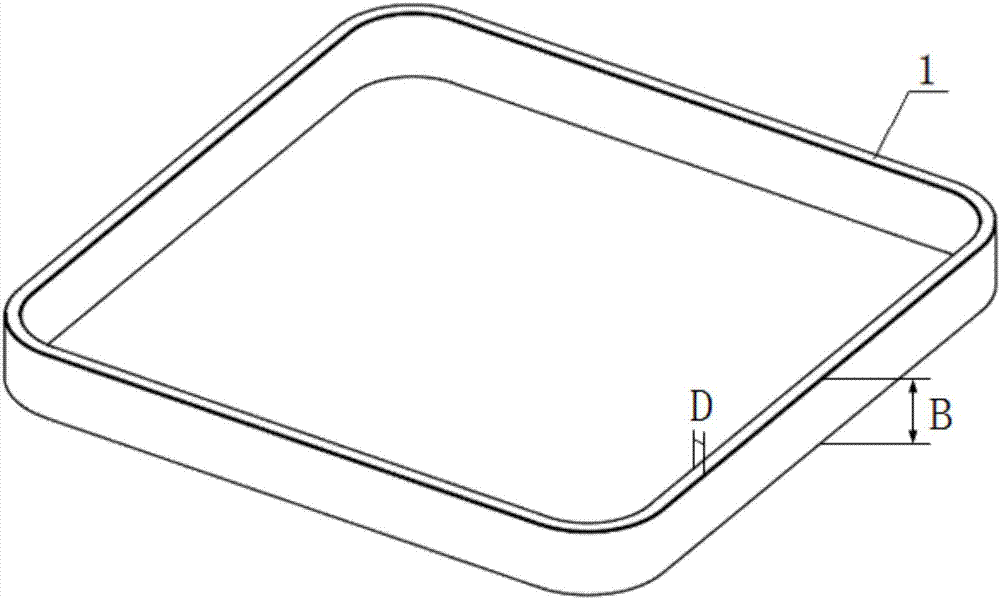

[0035] Specific implementation mode two: combination Figure 3 to Figure 11 To illustrate this embodiment, the thickness D of the rectangular cross section of the stirrup body 1 in this embodiment is 3 mm to 10 mm, and the width B of the rectangular cross section of the stirrup body 1 is 10 mm to 30 mm. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0036] In this embodiment, the thickness D of the rectangular cross-section of the stirrup body 1 and the range value of the width B of the rectangular cross-section of the stirrup body 1 are all commonly used optimal range values, which can be selected according to actual needs in the actual application process, and Not limited to the above range values.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination Figure 3 to Figure 11 To illustrate this embodiment, the cross-sectional shape of the stirrup body 1 in this embodiment along the circumferential direction is a closed circle, rhombus or rectangle. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0038] The circle in this embodiment includes an ellipse, and the rectangle includes a square.

[0039] The stirrup body 1 described in this embodiment is formed by sequentially winding FRP bundles 2 without overlapping sections. Its rectangular cross-sectional area and aspect ratio can be selected according to actual needs. For the rectangular closed rectangular section FRP stirrups, the chamfer radius and thickness ratio can be determined according to the molding process, actual construction feasibility and mechanical performance requirements. When used in combination, the stirrup bodies 1 of different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com