Expansion type yielding anchor rod

A pressure anchor and expansion technology, applied in climate change adaptation, sheet pile walls, excavation, etc., can solve problems such as shortening the construction period, achieve the effects of shortening construction time, improving durability and safety, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

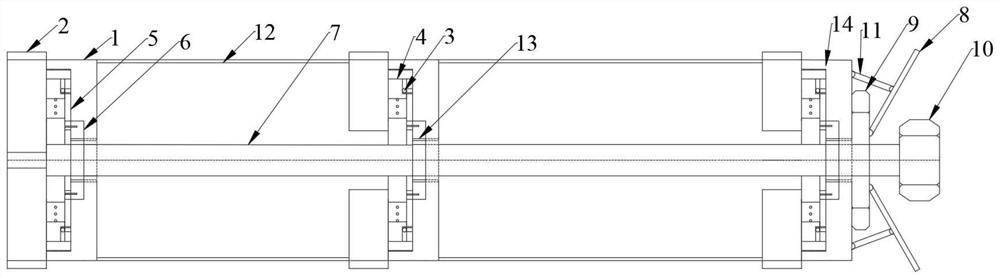

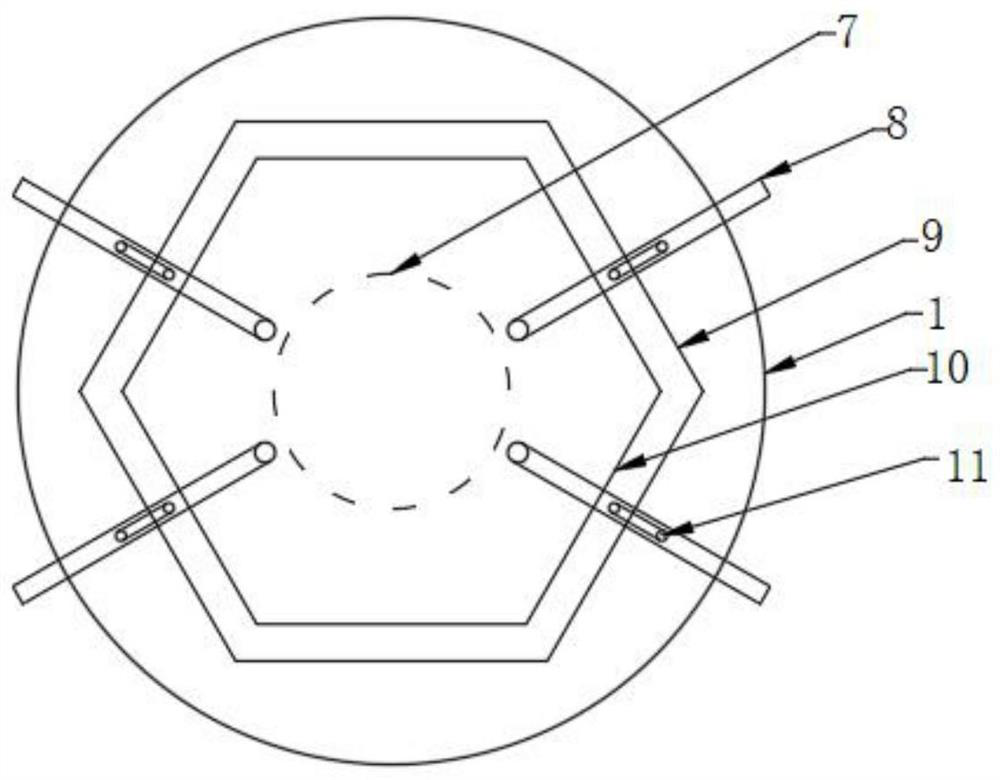

[0037] Example 1: Such as figure 1 As shown, an expansion type makes a barrier, including an outer anchor cylinder 1, an expansion, a pivot 7, a strut 8, anchor cap 10, and a bearing 12,

[0038] The outer anchor cylinder body 1 is provided with a pivot 7 in the axial center and the pivot 7 passes through the closed end of the outer anchor cylinder 1, and the anchor cap 10 is fixedly disposed on the end of the pivot 7 and anchor. The cap 10 is close to the closed end of the anchor cylinder 1, and the strut 8 is inclined to the closed end of the anchor barrel 1;

[0039] The expansion makes the pressing device comprises an inner anchor extension 2, a slider 4, a chute, and a transmission member;

[0040]The inner ring of the bearing 12 is fixed to the pivot 7, and the outer wall of the outer ring of the bearing 12 is in contact with the inner wall of the outer anchor cylinder body 1, and the outer anchor cylinder 1 is opened in the circumferential direction, the inner anchor expand...

Embodiment 2

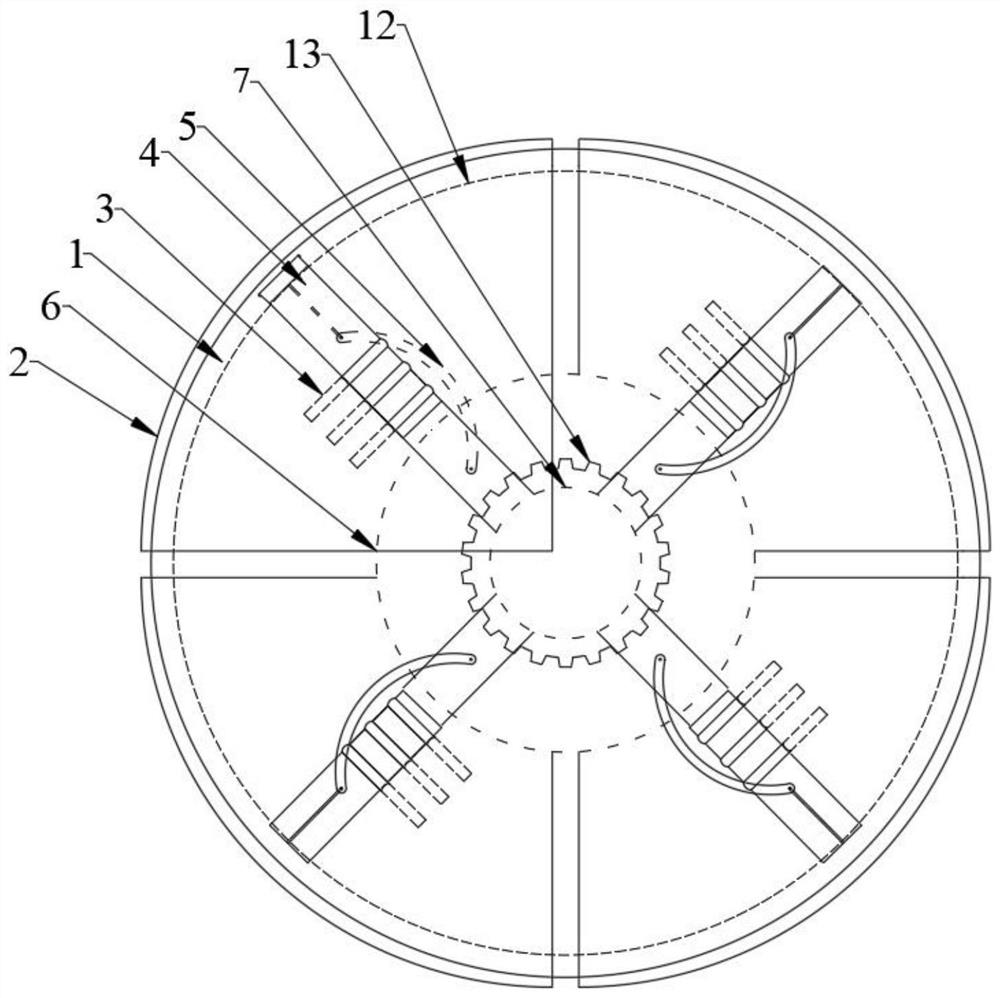

[0042] Example 2: The expansion type of the present embodiment is substantially the same as the expansion type of Example 1, and the difference is that figure 2 As shown, the sidewall of the chute has a bolt hole, and the bolt hole is fixedly provided which is stretchable shear bolt III, and the shear bolt III is perpendicular to the sliding direction of the slider 4;

[0043] The transmission member includes a transmission shaft 5, a rotary disk 6, and a gear 13, and the gear 13 is fixedly disposed on the pivot 7, the inner ring of the rotary disk 6 is engaged with the gear 13, and the rotary disk 6 is fixedly provided with a pin shaft I, the drive shaft 5 One end is arranged on the pin shaft I and the drive shaft 5 can rotate about the pin shaft 1, and the slider 4 is fixed to the pin shaft II, and the other end of the drive shaft 5 is arranged on the pin shaft II and the pin II can be wound. Pin II rotates;

[0044] The rotating disk 6 is provided with a space area having a siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com