Preparation method of CdS-loaded MIL-101(Cr) hydrogen-production photocatalyst

A technology of photocatalyst and aqueous solution, which is applied in the direction of catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, chemical instrument and method, etc. It can solve the problem of reducing surface area of photogenerated electrons, hole recombination rate, easy agglomeration, etc. problem, achieve the effect of reducing photocorrosion phenomenon and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

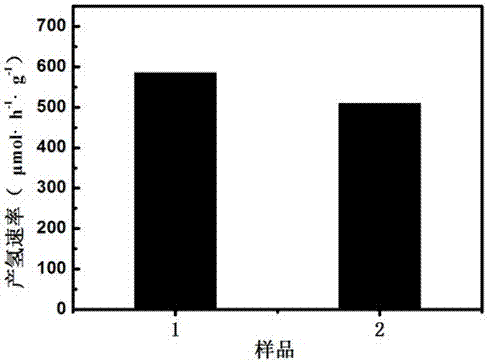

Embodiment 1

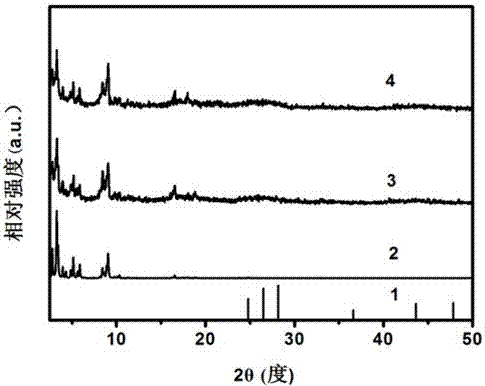

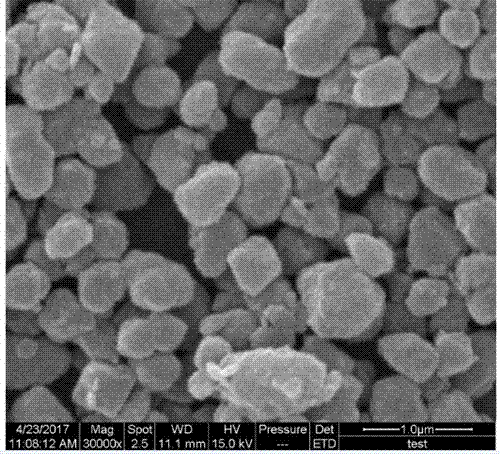

[0020] Example 1: The preparation method of a kind of MIL-101 (Cr) loaded CdS hydrogen production photocatalyst of the present embodiment is completed according to the following steps:

[0021] Step 1, the Cr(NO) of the terephthalic acid of 0.1656g and 0.3992g 3 ) 3 9H 2 O. 0.05mL of HF was added to distilled water, stirred with a glass rod for 3 minutes, then transferred to a high-temperature hydrothermal reaction kettle, reacted at 220°C for 8h, centrifuged to obtain a precipitate, and dried at 80°C to obtain 0.2g MIL-101(Cr);

[0022] Step 2: Put 0.2g of MIL-101(Cr) obtained in Step 1 into a round bottom flask and add 50mL of distilled water, then heat, stir, condense and reflux at 110°C in a constant temperature oil bath for 12h, centrifuge to obtain a precipitate, and dry at 80°C Finally, put MIL-101(Cr) into a round bottom flask and add 50mL of absolute ethanol, heat, stir, condense and reflux twice in a constant temperature oil bath at 80°C, each time for 12h; centrif...

Embodiment 2

[0026] The difference between this embodiment and Example 1 is: the Cd(AC) described in step 3 2 The concentration of the substance in the aqueous solution is 0.7mol / L, and the amount added is 0.15mL; Na described in step 3 2 The molar concentration of the S aqueous solution is 0.7mol / L, and the added amount is 0.15mL. Other steps and parameters are the same as in Example 1. A MIL-101(Cr)-supported CdS photocatalyst for hydrogen production was obtained with a mass fraction of MIL-101(Cr) of 85% and a mass fraction of CdS of 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com