Left-handed material based on cavel-shaped basic unit structure

A basic unit, left-handed material technology, applied in electrical components, antennas and other directions, can solve the problems of lack of application flexibility and diversity, low practical value, many adjustment restrictions, etc., to achieve compact structure, simple structure, high capacitance effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

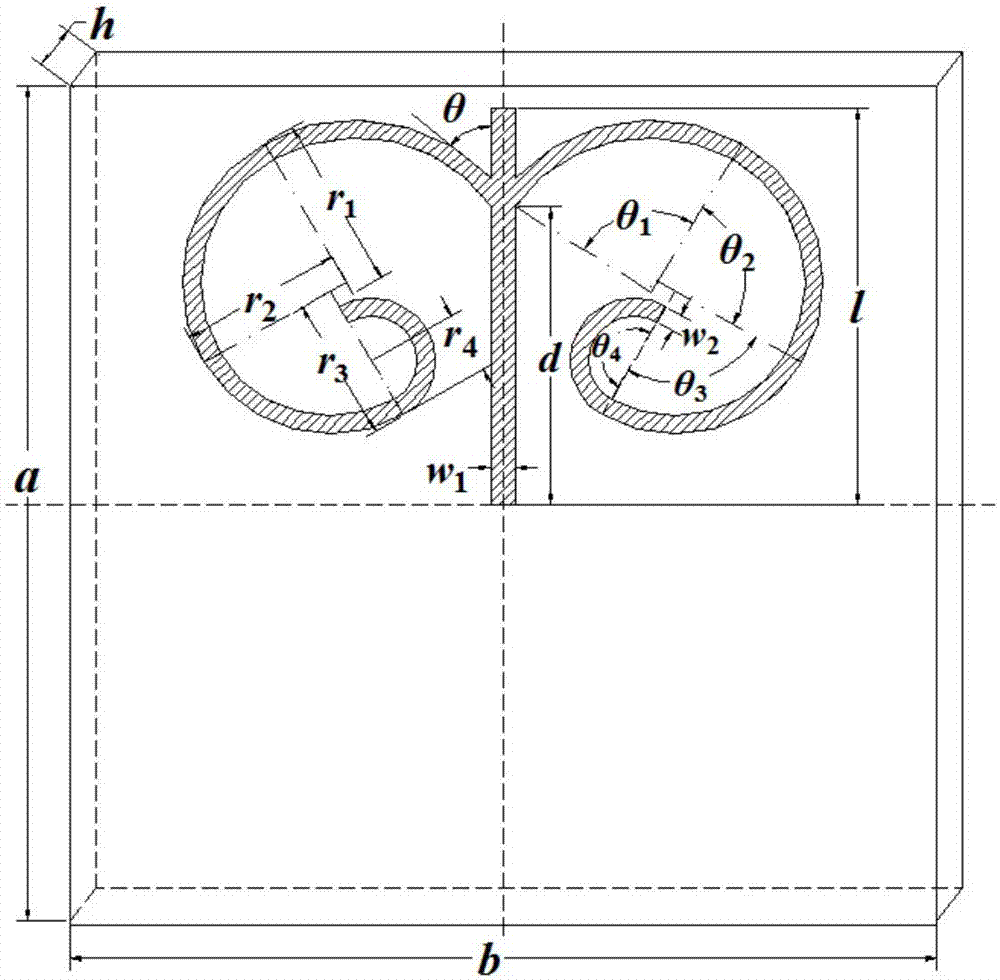

Embodiment 1

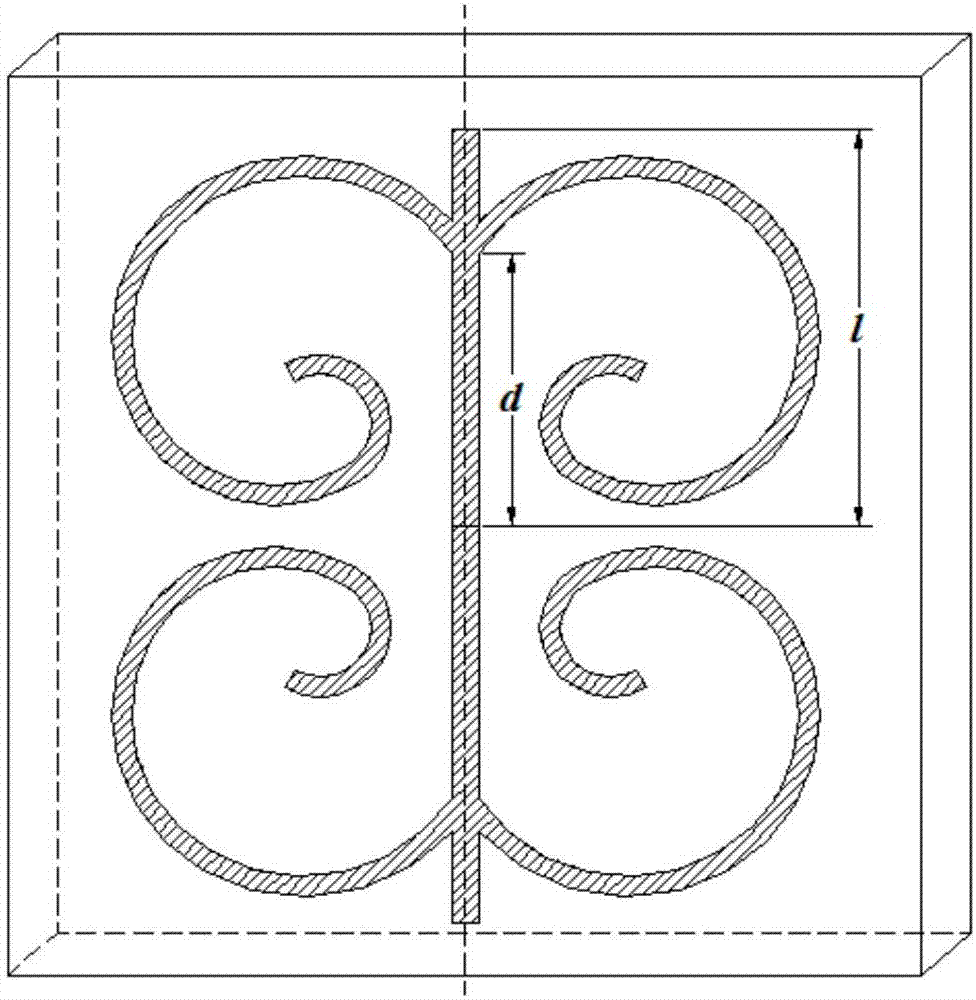

[0035] Embodiment 1: see figure 2 , parameterized with figure 1 same. In this embodiment, n=2, that is, figure 1 The claw-like structure of the Zhongliang conductor layer is copied into two parts, and they are rotated 180° with the midpoint of the bottom edge of the metal rod as the center of the circle, forming a two-piece petal-shaped left-handed material. The length of the metal rod is l=6mm and the width is w 1 = 0.4 mm. The distance from the connection point between the arc-shaped recursive spiral structure and the metal rod to the bottom edge of the metal rod is d=4.0mm. The angle between the tangent line at the starting point of the spiral structure and the metal rod is θ=30°, and the radii of the 4 arcs of the spiral structure are r 1 = 3mm, r 2 = 2.7 mm, r 3 = 2.4mm, r 4 =1.05mm, the width is w 2 = 0.3 mm. Depend on image 3 , 4 It can be seen that the equivalent dielectric constant is negative in the 2.00-2.82GHz and 3.60-5.00GHz frequency bands, the equ...

Embodiment 2

[0036] Example 2: see Image 6 , parameterized with figure 1 same. In this embodiment, n=6, that is, figure 1 The croissant structure of the Zhongliang conductor layer is copied into 6 parts, and they are rotated by 60° with the midpoint of the bottom edge of the metal rod as the center of the circle, forming a six-piece petal-shaped left-handed material. The length of the metal rod is l=5mm and the width is w 1 = 0.3 mm. The distance from the connection point between the arc-shaped recursive spiral structure and the metal rod to the bottom edge of the metal rod is d=3.7mm. The angle between the tangent line at the starting point of the spiral structure and the metal rod is θ=10°, and the radii of the 4 arcs of the spiral structure are r 1 = 1.06mm, r 2 = 0.91 mm, r 3 = 0.76mm, r 4 =0.305mm, width is w 2 = 0.15 mm. Depend on Figure 7-9 It can be seen that the real part of the equivalent permittivity of the structure in the simulation frequency range is below 0, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com