Optical fingerprint sensor module and manufacturing method thereof

A technology of a fingerprint sensor and a manufacturing method, applied in the directions of instruments, character and pattern recognition, computer parts, etc., can solve the problems of complex manufacturing method steps, high cost, low efficiency, etc., and achieve easy control, improve yield, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

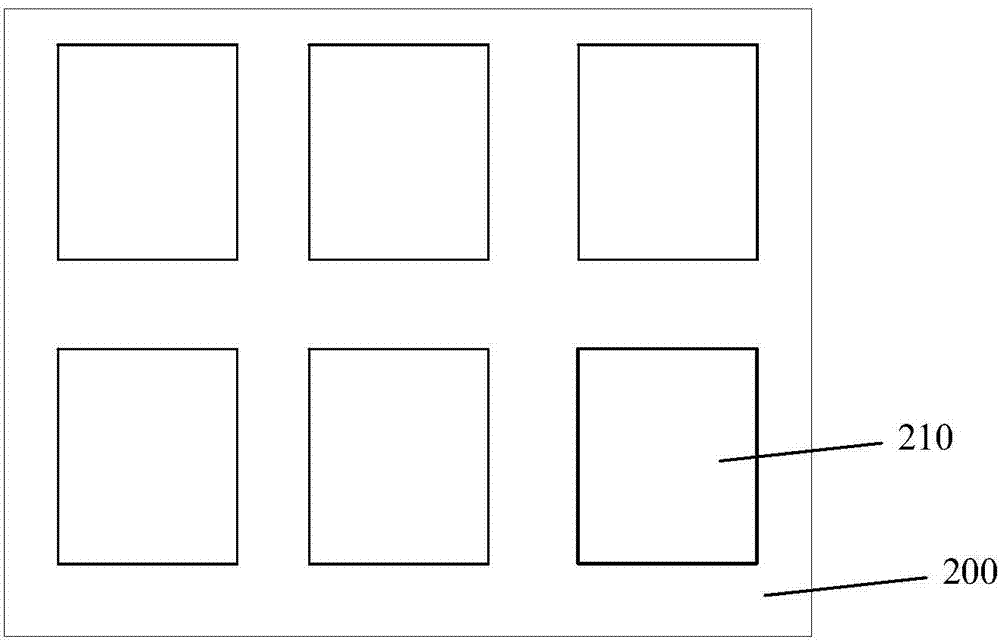

[0042] A manufacturing method of an existing optical fingerprint sensor module is as follows: Figure 2 to Figure 6 shown.

[0043] refer to figure 2 , provide a glass substrate 200, the glass substrate 200 includes a plurality of undivided sub-substrates 210, that is, the sub-substrate 210 is a part of the glass substrate 200 (the glass substrate 200 includes all the sub-substrates 210 and other sub-substrates 210 between the sub-substrates 210 part).

[0044] continue to refer figure 2 , fabricate the circuit block (not shown) of the optical fingerprint sensor on the surface of each sub-substrate 210 . One circuit block is fabricated on the surface of a sub-substrate 210 , that is, multiple independent circuit blocks are fabricated on the surface of the glass substrate 200 .

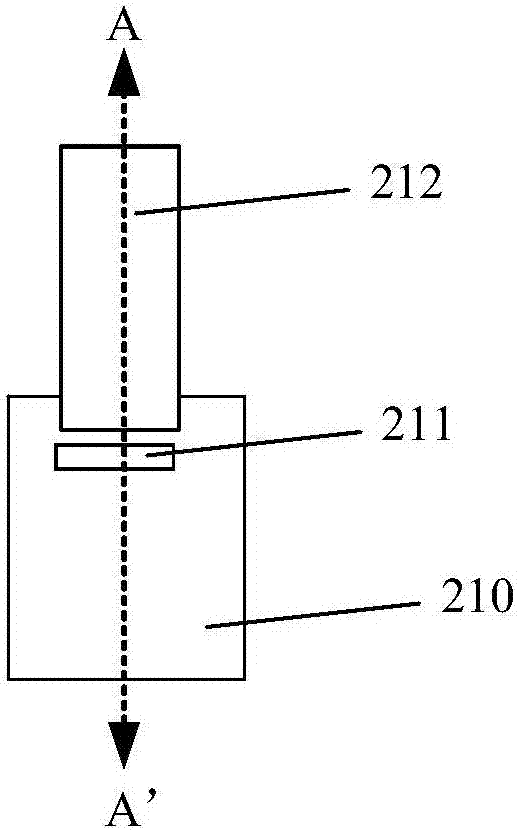

[0045] Please refer to image 3 , cutting the glass substrate 200 on which the circuit block is fabricated, and cutting into each sub-substrate 210 with the circuit block. Then, various binding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com