Exhaust structure of smoke exhaust

The technology of a range hood and a casing is applied in the field of kitchen and bathroom, which can solve the problems of incapability of relative movement and relative rotation, and achieve the effect of improving operation flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

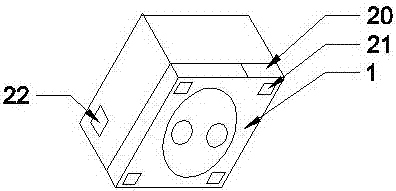

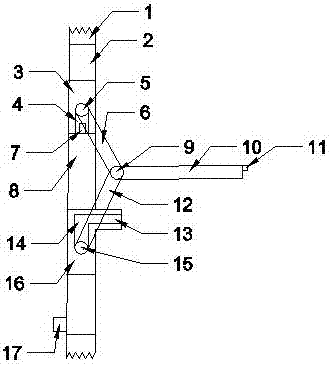

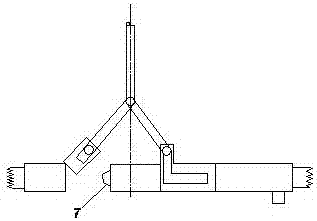

[0023] An exhaust structure of a range hood, wherein the range hood includes: a casing, an exhaust structure, a lighting lamp, an alarm, an exhaust pipe (not shown in the figure), a touch screen and touch buttons arranged on the touch screen; the exhaust structure Including disc body, first valve plate, first slide rail, first slide pin, first pole, contact point, middle seat, pivot point, valve stem, transmission pin, second pole, second slide rail, second pole Three slide rails, the second sliding pin, the second valve plate, the handle and the driving part; the driving part includes an electromagnetic coil, an armature, and the armature is connected to the valve stem. The upper and lower half-ring grooves are connected to each other; the transmission pin protrudes from the upper side of the valve stem, the transmission pin is stepped, the diameter of the upper end is larger than the diameter of the lower end, and the transmission pin is sleeved in the double half-ring groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com