Low-noise alarming disc type brake pad

A disc brake pad, low-noise technology, applied in the direction of noise/vibration control, brake type, brake components, etc., can solve problems such as unimaginable consequences, friction pad falling off, brake pad falling off, etc., to prevent safety accidents and prevent friction. The effect of smaller coefficients and better braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

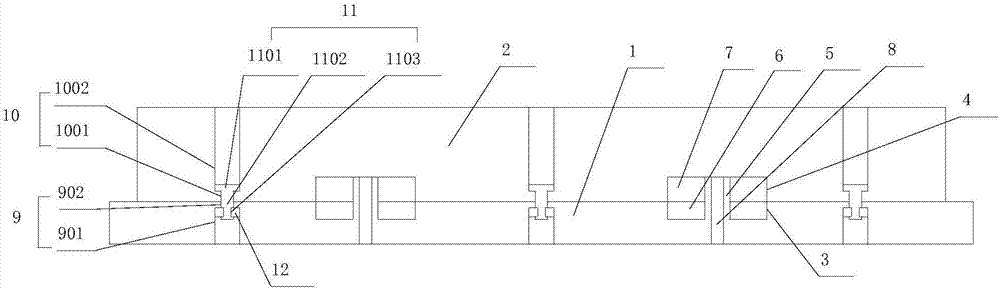

[0011] refer to figure 1 , the present invention proposes a low-noise alarm disc brake pad, including a steel plate 1 and a friction plate 2, wherein:

[0012] The friction plate 2 is fixed on the steel plate 1, and the side of the steel plate 1 close to the friction plate 2 is provided with a plurality of first grooves 3, and the side of the friction plate 2 close to the steel plate 1 is provided with the first groove 3 at a position corresponding to the first groove 3. The second groove 4 connected to the groove 3, the first groove 3 is provided with a boss 5 integrally formed with the steel plate 1, the height of the boss 5 is equal to the sum of the depth of the first groove 3 and the second groove 4, the steel plate 1 is located below the boss 5 and is provided with cooling holes 8 and the boss 5 is penetrated by the cooling holes 8 , and the number of the cooling holes 8 is consistent with the number of the bosses 5 . The first groove 3 is provided with a sound-absorbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com