Energy-saving auxiliary cooling device of concrete milling machine

A technology of auxiliary cooling and milling machine, which is applied in the cooling of engine, heat treatment device of fuel, liquid cooling, etc., can solve the problems of increased risk, waste of resources, and reduced working efficiency of milling machine, etc., and achieves increased cooling efficiency, Cool full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

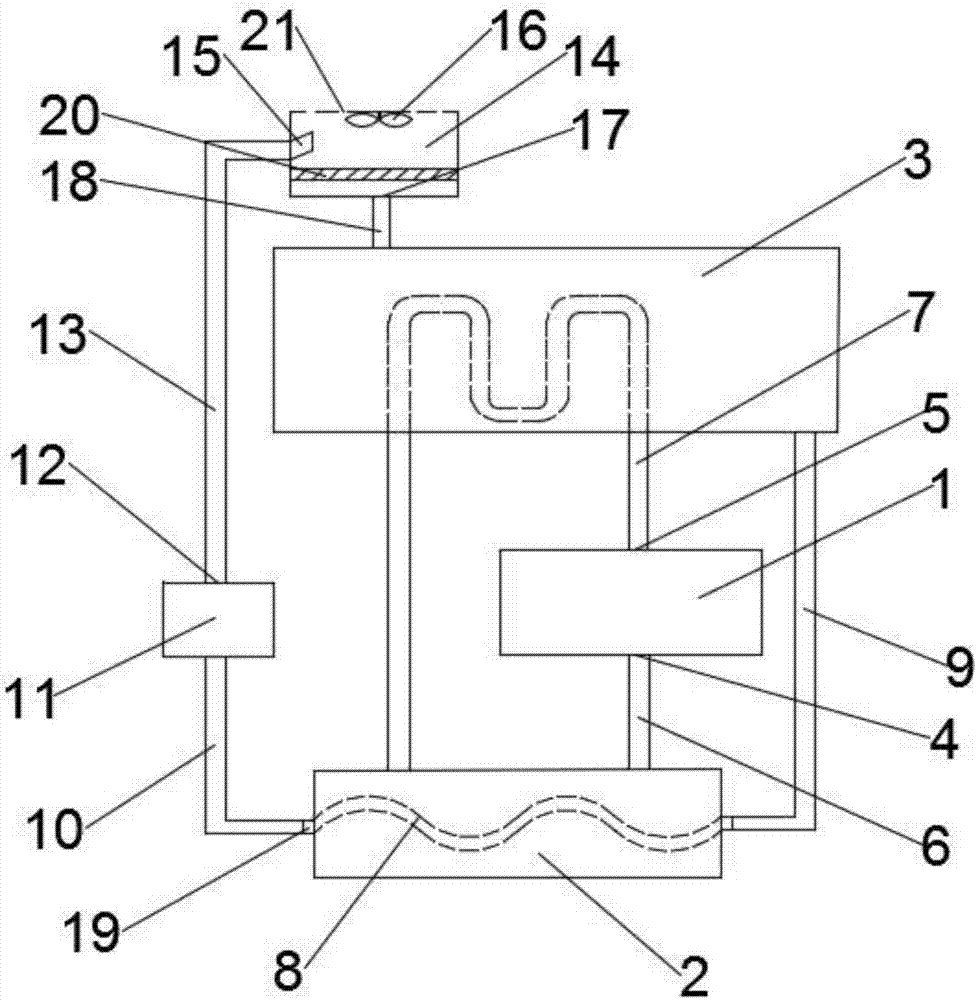

[0021] Such as figure 1 As shown, the present invention provides an auxiliary cooling device for a concrete energy-saving milling machine, which includes a fuel tank 1, an engine 2 and a water tank 3, and is characterized in that: the bottom of the fuel tank 1 is provided with an oil suction port 4, and The top of the tank 1 is provided with an oil return port 5, one side of the engine 2 is connected to the oil suction port 4 through the oil suction pipe 6, and the other side is connected to the oil return port 5 through the oil return pipe 7, and the oil return pipe 7 part Placed in the water tank 3, and twisted and folded in the water tank 3, the engine 2 is provided with a cooling water pipe 8, one end of the cooling water pipe 8 is connected to the bottom of the water tank 3 through the water inlet pipe 9, and the other end is connected to the water pump through the suction pipe 10 11. The water outlet 12 of the water pump 11 is connected with a water outlet pipe 13, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com