Segmented serial electric rotor turbofan engine and control method thereof

A turbofan engine, tandem technology, applied in the direction of machine/engine, jet propulsion, etc., can solve the problems of occupying combustion chamber space, prone to surge, low combustion efficiency, etc., to increase combustion space and reduce surge The probability of vibration and the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

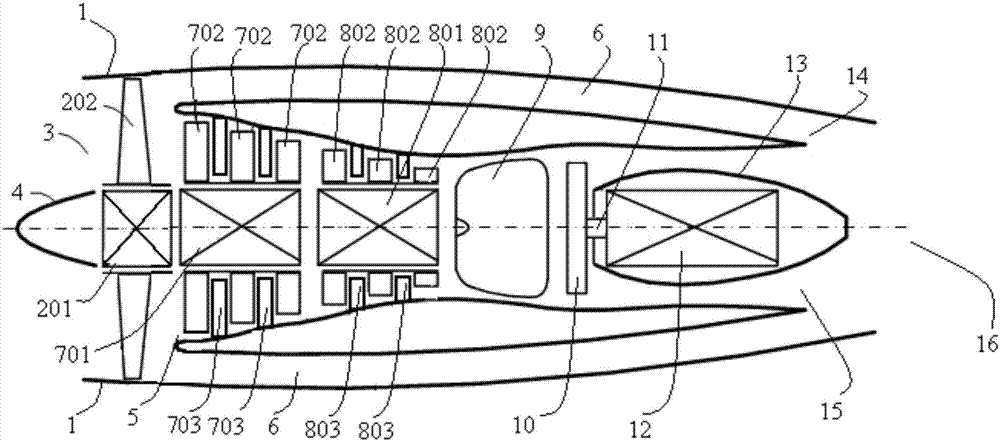

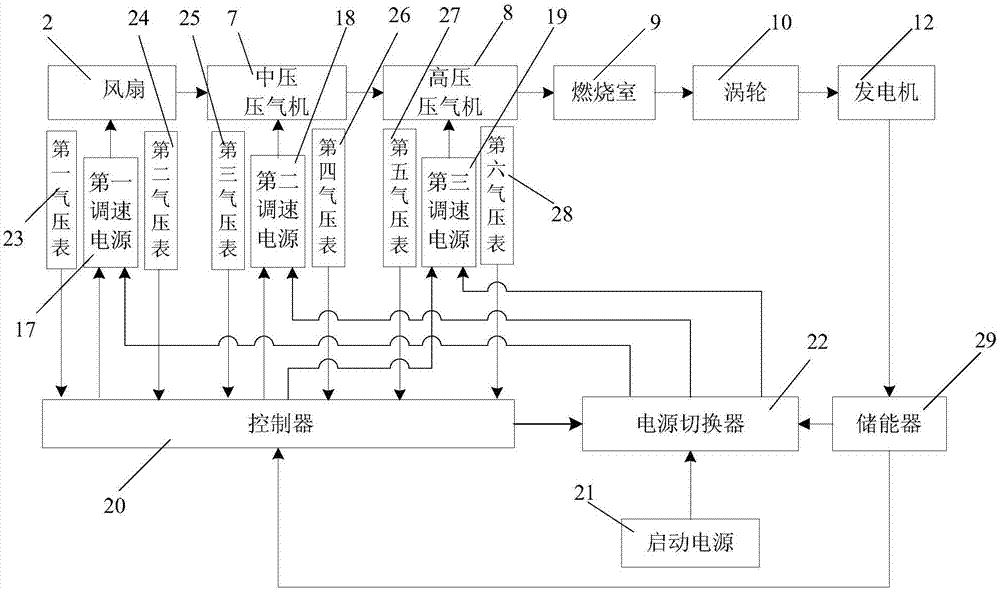

[0046] refer to figure 1 , the segmented tandem electric rotor turbofan engine of the present invention comprises: casing 1, engine inlet 3, fan 2, medium pressure compressor 7, high pressure compressor 8, combustion chamber 9, turbine 10, generator 12 and control system.

[0047] The casing 1 is provided with an engine air inlet 3, and the front portion of the engine air inlet 3 is provided with a fan 2, the fan 2 is an axial fan, and the fan 2 is fixed in the casing 1 by a fan bracket; The middle part is divided into an inner duct 5 and an outer duct 6, the end of the inner duct 5 is provided with an inner duct exhaust port 15, the rear of the outer duct 6 is provided with an exhaust cone 13, and the tail end of the outer duct 6 is provided with a Outer duct exhaust port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com