Automatic jacking truss crane system construction operation platform for mounting of steel structure

A work platform and steel structure technology, which is applied in the direction of scaffolding supported by housing structure, housing structure support, housing structure support, etc., to achieve the effect of saving cost, improving overall stability, safety and reliability, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

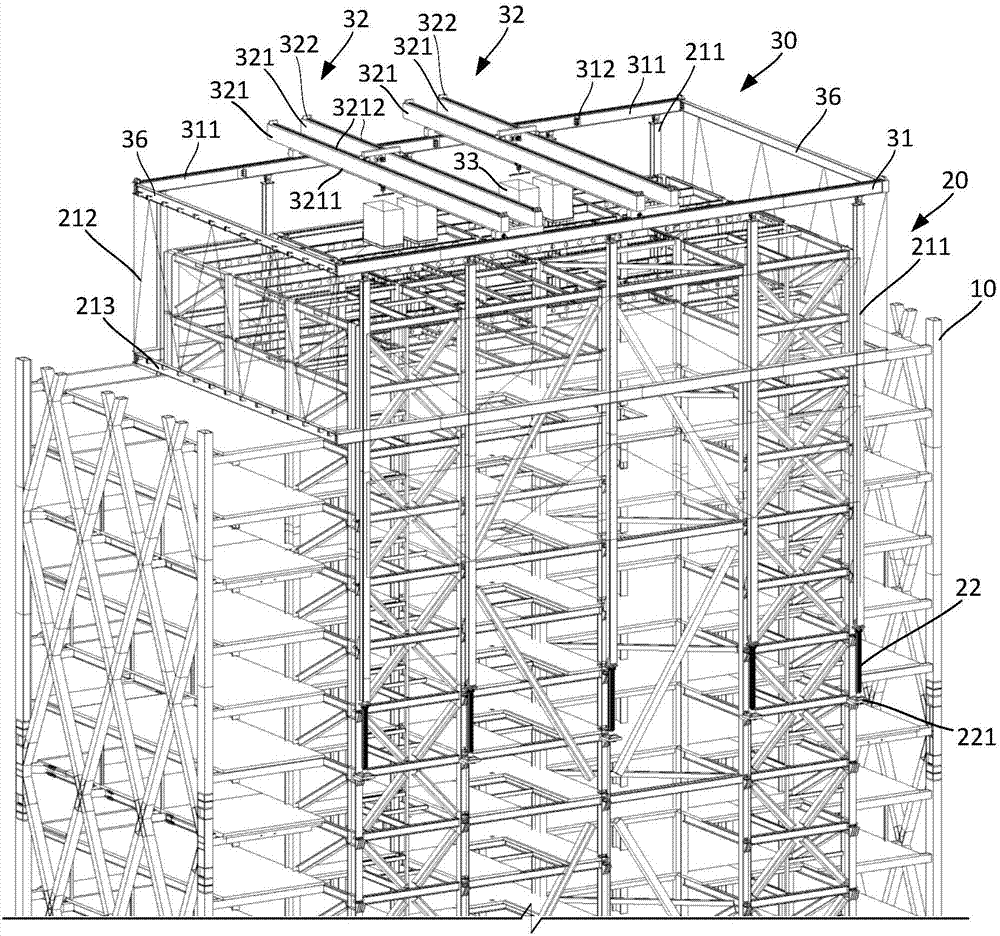

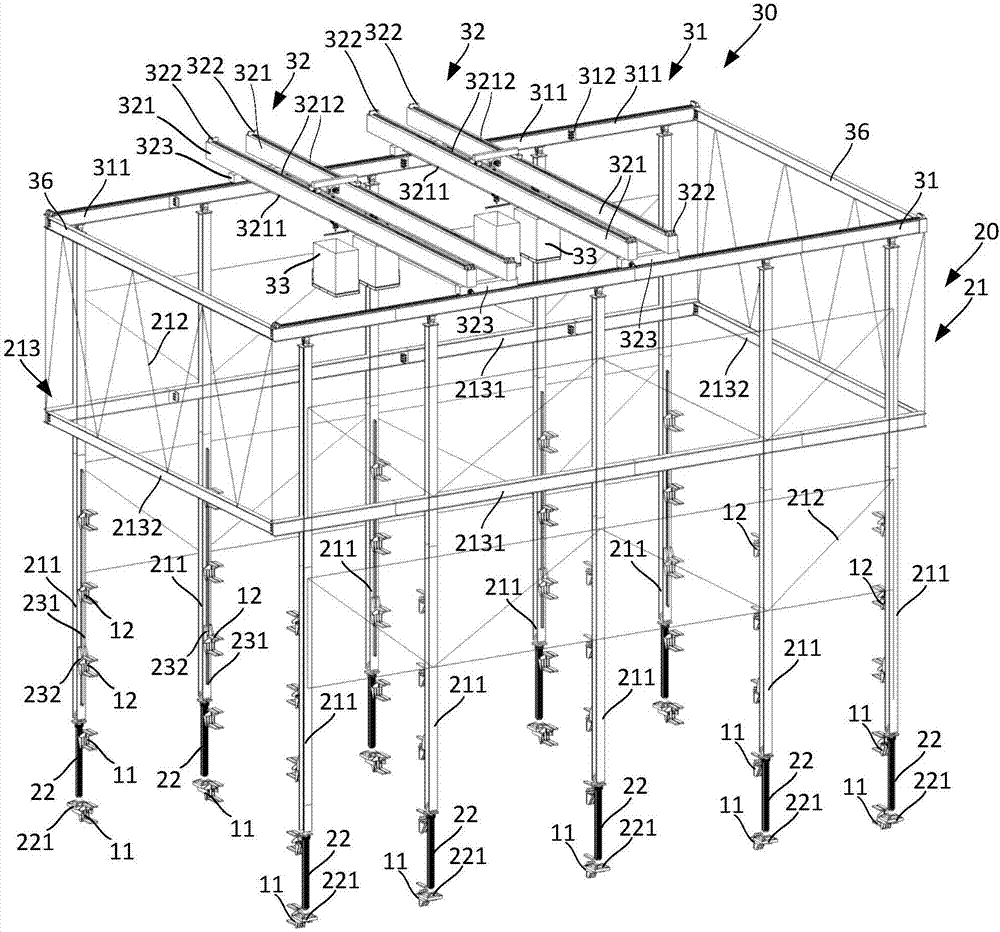

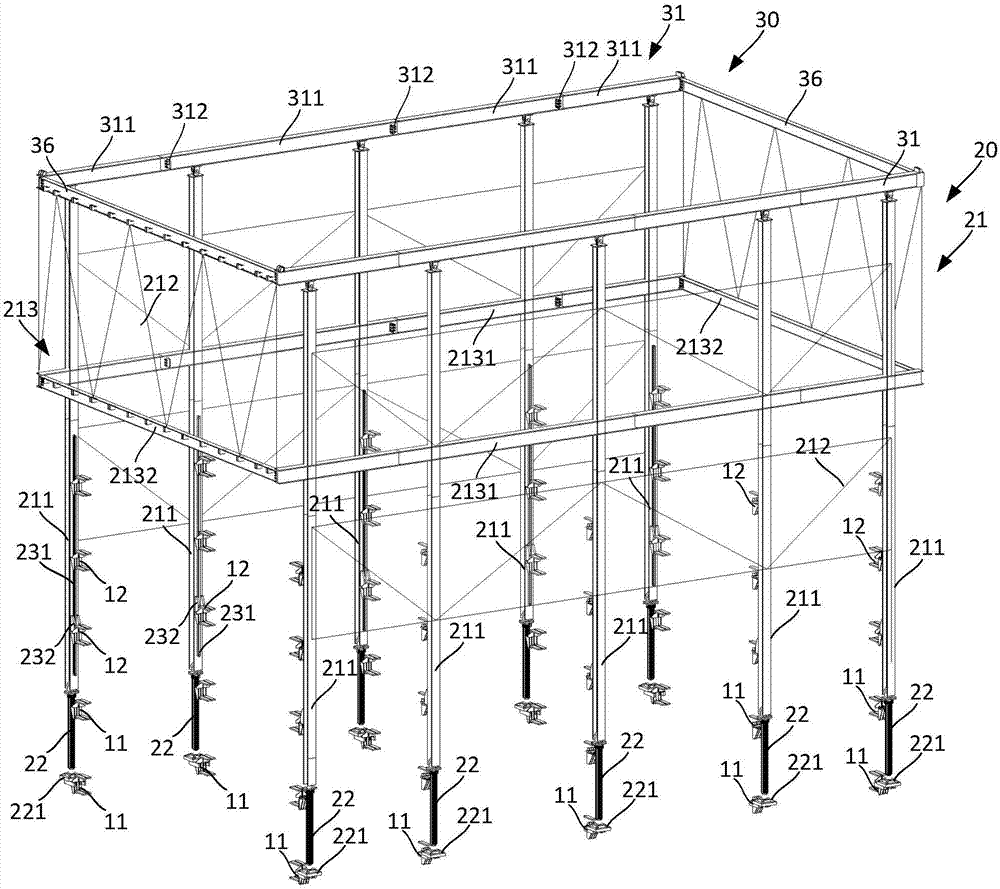

[0058] refer to figure 1 , The present invention provides a construction operation platform of an automatic jacking truss crane system for steel structure installation, which is used for the construction of steel structures, including the assembly construction of steel structure buildings, and also includes the assembled construction of steel components. The automatic climbing construction operation platform system of the present invention is attached to the steel structure, and automatically climbs up with the construction of the steel structure, providing a convenient construction operation platform for the construction of the steel structure, and the components of the steel structure are hoisted without using a tower crane. The truss crane system in the automatic climbing construction work platform system of the present invention can realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com