Lightweight rapid-hardening structural fireproofing thermal-insulation prefabricated slab free of formwork removing and manufacturing method thereof

A technology of fire prevention and heat preservation and prefabricated panels, which is applied in the direction of heat preservation, fire protection, building construction, etc., and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

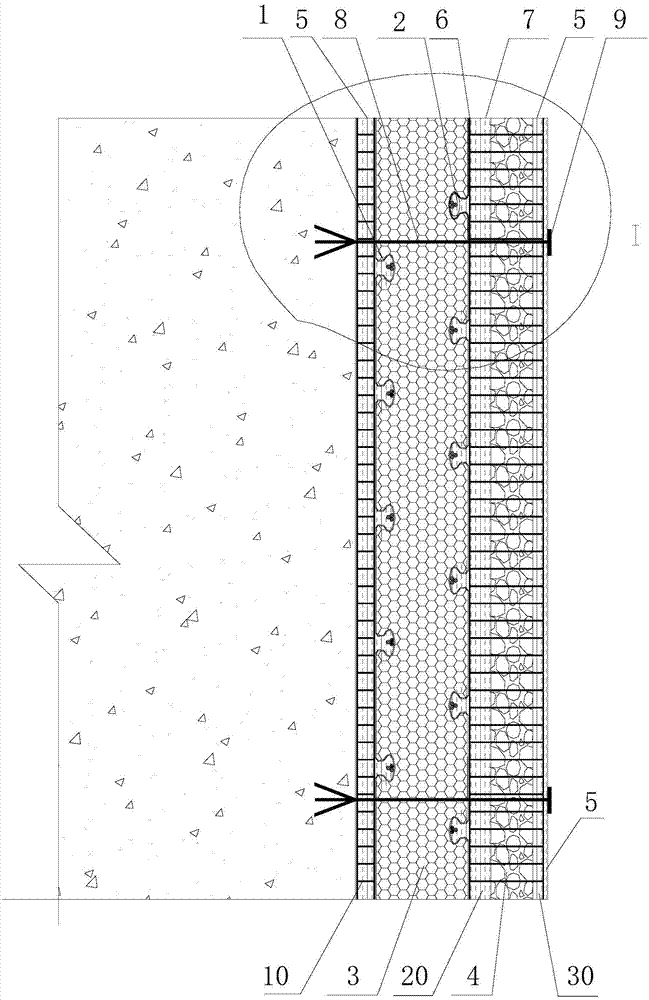

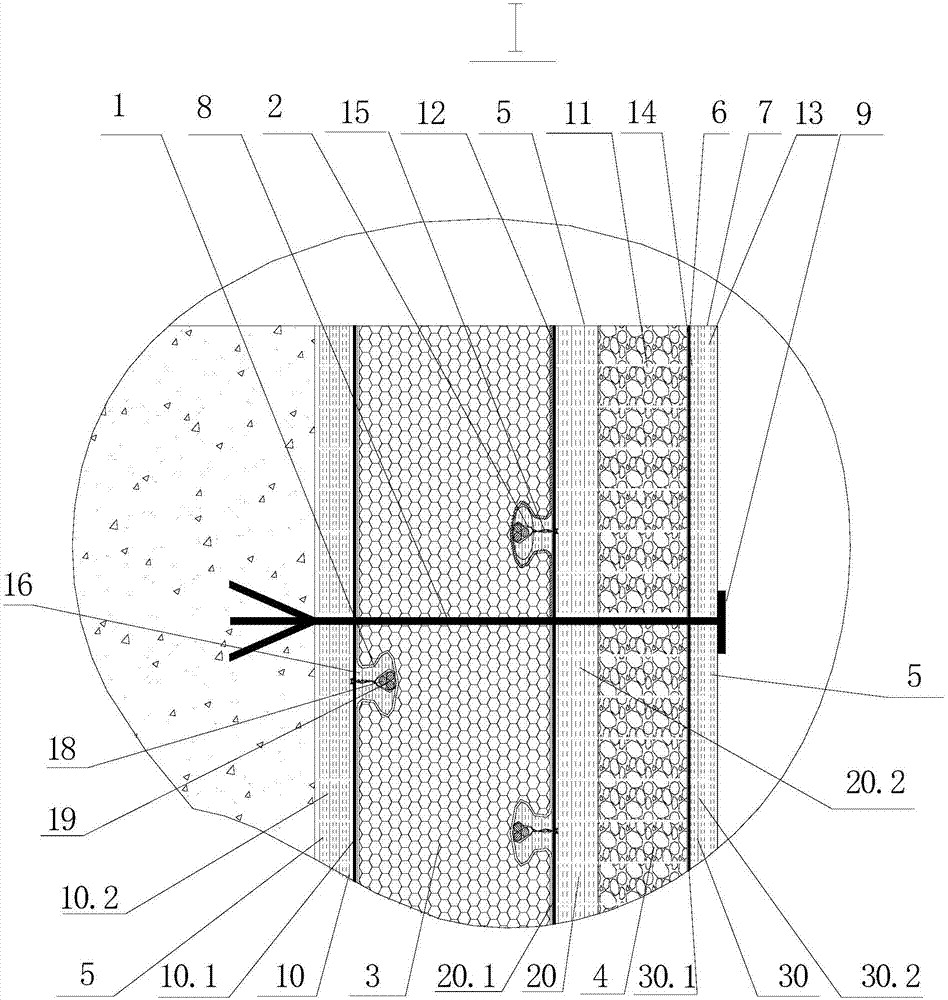

[0050] As shown in the figure, a light-weight, fast-hardening and form-removing-free structural fireproof and thermal insulation prefabricated panel can be directly used as the external formwork of cast-in-place concrete structural engineering, and can be integrally formed into concrete without formwork removal. The surface layer of the structural engineering, including the thermal insulation core layer 3, the lightweight rapid-hardening fireproof layer 4 and at least three layers of reinforced rapid-hardening structure 5, the enhanced rapid-hardening structure 5 includes a reinforcement mesh 6 and a rapid-hardening adhesive mortar layer 7; The enhanced rapid-hardening structure 5 is arranged between the thermal insulation core layer 3 and the light-weight rapid-hardening fireproof layer 4 .

[0051] The inner surface of the thermal insulation core layer 3 is uniformly provided with first grooves 1 along the length direction, and the outer surface of the thermal insulation core...

Embodiment 2

[0070] As shown in the figure, other structures are the same as those in Embodiment 1, and the enhancement network is improved as follows.

[0071] The first rapid-hardening reinforcement structure 10 includes a first reinforcement net 10.1 and a first rapid-hardening adhesive mortar layer 10.2, the first reinforcement net 10.1 is a three-dimensional net 11, and the three-dimensional net 11 includes a bottom line net 12 and an upper line Net 13, the nodes of the bottom line net 12 and the surface line net 13 are fixedly connected with vertical ribs 14. The three-dimensional net 11 can be a net woven with high-strength engineering plastic fiber bundles, and the vertical ribs 14 have a certain rigidity and can support the space of the required three-dimensional net so as to fill the rapid-hardening adhesive mortar layer. The bottom line net 12 is located on the inner surface of the heat preservation core layer 3; the surface line net 13 is 3-6mm away from the outer surface of th...

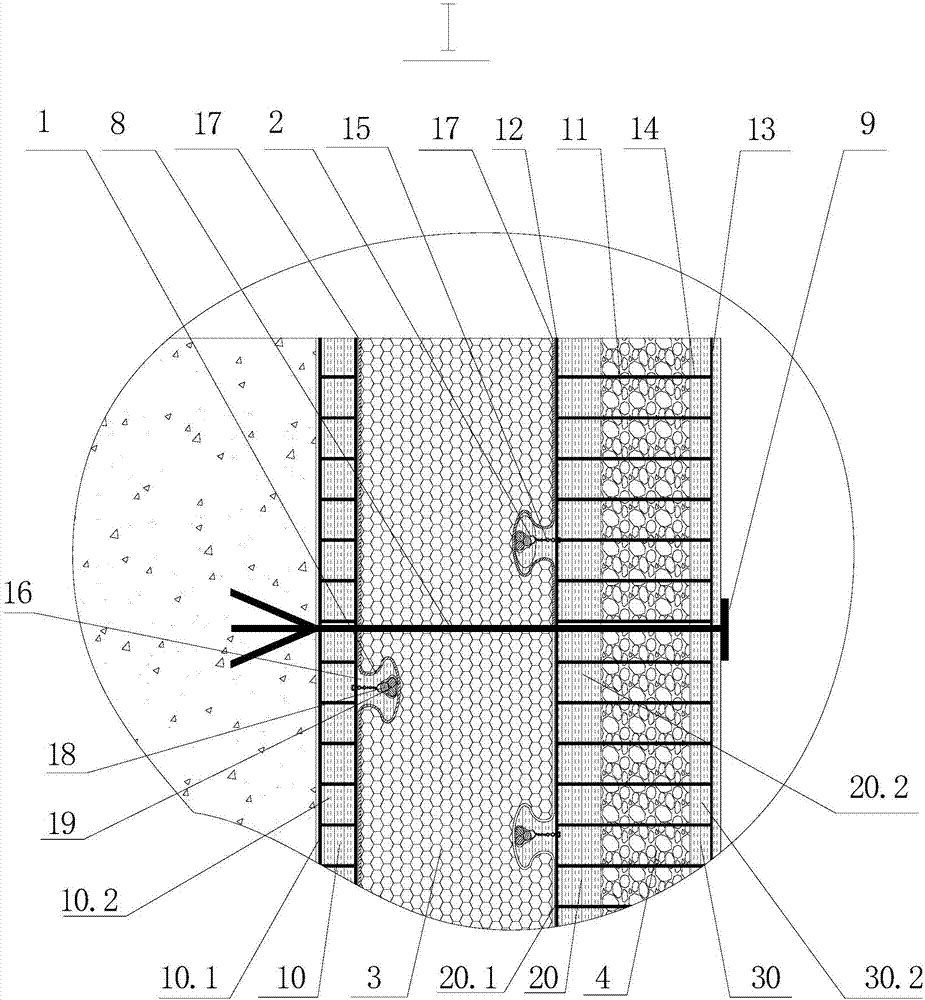

Embodiment 3

[0085] The upper and lower surfaces of the thermal insulation core layer 3 are bonded and fixed with aluminum foil 17, and the aluminum foil 17 also passes through and covers the inner surface of the second groove. The thickness of the aluminum foil 17 is preferably 0.5-2 mm, because the second groove The groove is in a concave shape with a large inside and a small outside, which enables the insulation board with aluminum foil and the reinforced rapid hardening structure to be integrated with high strength. At the same time, the fireproof performance of the thermal insulation board is greatly enhanced, and the thermal conductivity is also greatly reduced. The thermal conductivity of the light-weight, fast-hardening and form-removing-free structural fireproof and thermal insulation prefabricated panel is as low as 0.01W / (m·K).

[0086] Further, at least one layer of fiber prepreg is bonded and fixed on the outside of the aluminum foil; the fiber prepreg is bidirectional carbon f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com