Preparation Method for Improving the Inhomogeneity of Eutectic Carbide in Cr12 Die Steel

A technology of eutectic carbide and uniformity is applied in the field of preparation of improving the non-uniformity of eutectic carbide of Cr12 forging work die steel, which can solve the problem that the non-uniformity is difficult to meet the requirements, and reduce the difficult deformation area. , The effect of reducing the degree of segregation and improving the surface plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

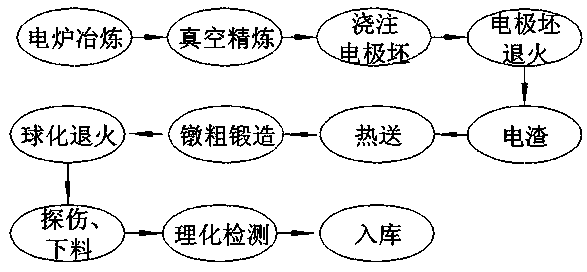

[0021] A preparation method for improving the unevenness of eutectic carbides in Cr12 type die steel, such as figure 1 , 2 As shown, the process flow of the method is as follows: electric furnace smelting + vacuum refining + casting electrode blank + electrode blank annealing, hot-cut riser → electroslag + heat transfer → heating + upsetting forging to finished product → annealing → blanking, flaw detection, physical and chemical testing; This preparation method comprises the steps:

[0022] Step S01: steelmaking, electric furnace smelting + vacuum refining + low-temperature casting electrode blank (φ500), the chemical composition is shown in Table 2 below;

[0023] Table 2 Chemical composition

[0024]

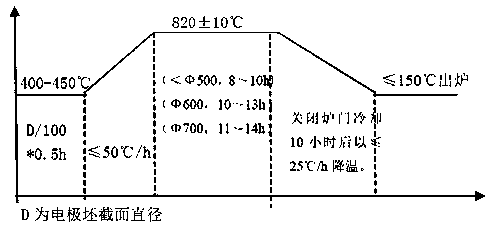

[0025] Step S02: Anneal the electrode blank, measure the temperature of the electrode blank ingot body after the electrode is eagerly cut the riser, the measured minimum temperature is 380°C, and the electrode blank is kept at 400-450°C for 2.5h as required, and the hold...

Embodiment example 2

[0031] A preparation method for improving the unevenness of eutectic carbides in Cr12 type die steel, such as figure 1 , 3 As shown, the process flow of the method is as follows: electric furnace smelting + vacuum refining + casting electrode blank + electrode blank annealing, hot-cut riser → electroslag + heat transfer → heating + upsetting forging to finished product → annealing → blanking, flaw detection, physical and chemical testing; This preparation method comprises the steps:

[0032] Step S01: Steelmaking, electric furnace smelting + vacuum refining + low temperature casting electrode billet (φ600), the smelting composition is shown in Table 3 below;

[0033] Table 3 Chemical composition

[0034]

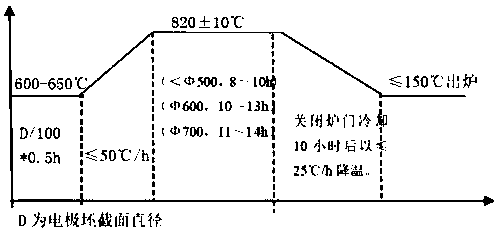

[0035] Step S02: Anneal the electrode blank, measure the temperature of the electrode blank ingot after the electrode is eagerly cut the riser, the measured minimum temperature is 545°C, and the electrode blank is kept at 600-650°C for 3 hours as required, and the holdi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com