Full-automatic rotary inclined plane filling machine for resin lens

A resin lens, fully automatic technology, applied in other home appliances, optical components, home appliances and other directions, can solve the problems of low quality stability of lens production, serious environmental hazards, low work efficiency, etc., to reduce the labor intensity of employees, reduce The effect of labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

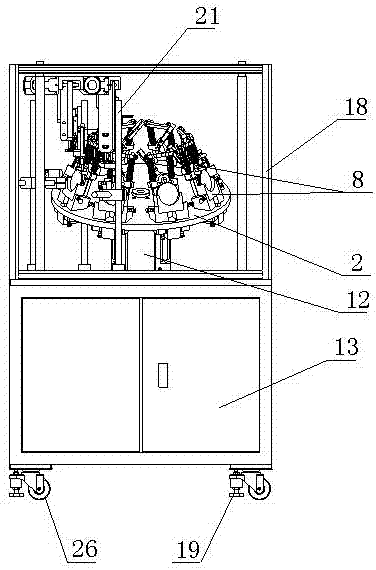

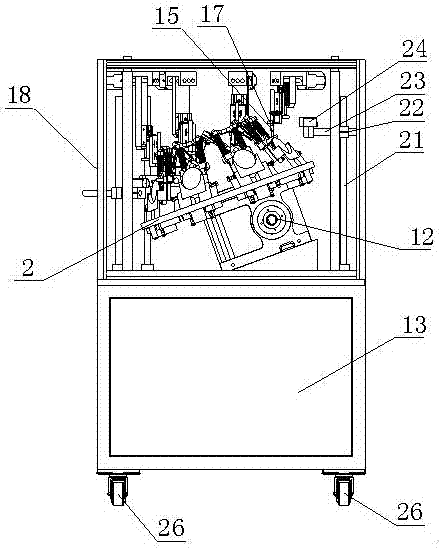

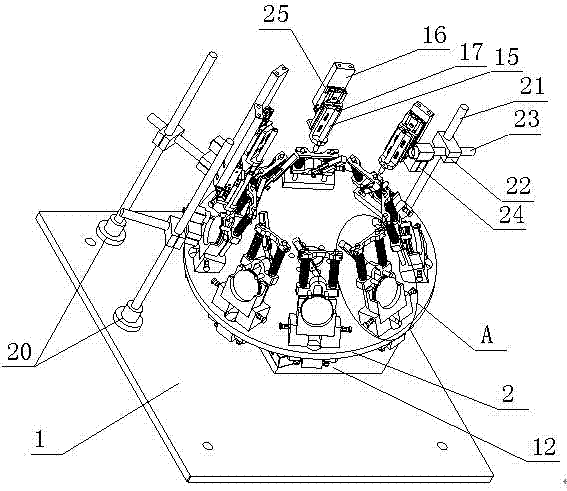

[0013] The present invention is described in further detail now in conjunction with accompanying drawing. The accompanying drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so that they only show the components relevant to the present invention.

[0014] For specific examples, see figure 1 , figure 2 , image 3 and Figure 4 , a fully automatic rotary slope filling machine for resin lenses, comprising an inclined rotating disk 2, a control cabinet 13, a protective cabinet 18, a vertical support rod 21 and a cylinder fixing plate 16, the protective cabinet 18 is arranged above the control cabinet 13, A workbench 1 is provided between the protective cabinet 18 and the control cabinet 13, and an eight-equal divider 12 is provided on the workbench 1, and the inclined rotating disk 2 is obliquely arranged on the eight-equal divider 12, so that Eight filling fixtures 8 are uniformly arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com