OSB clipper

A planer and plank technology, which is applied to wood processing appliances, processing machines for manufacturing flat surfaces, manufacturing tools, etc., can solve the problems of OSB plank deviation, OSB plank fixation, OSB plank size deviation, etc., to prevent loosening. , avoid displacement, improve the effect of flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

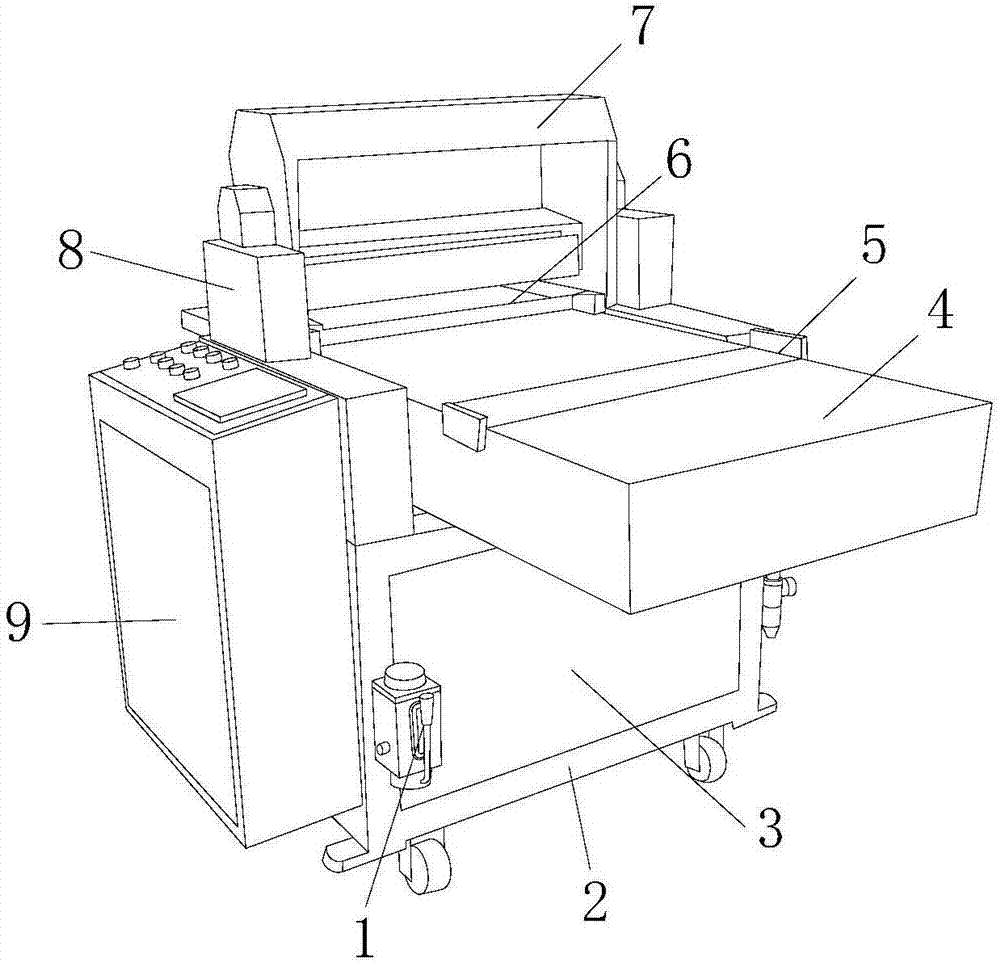

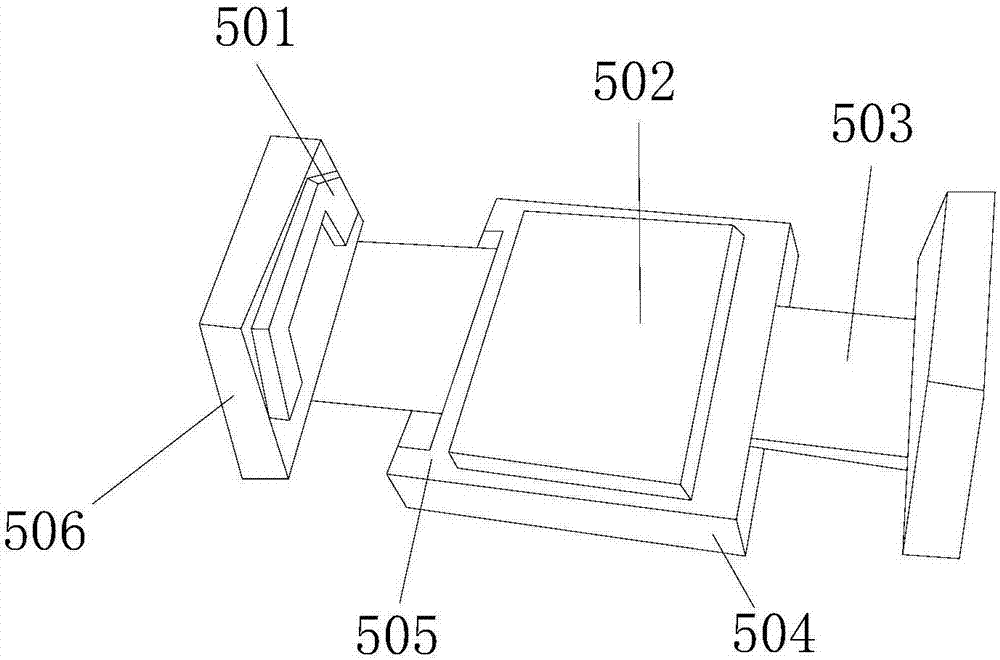

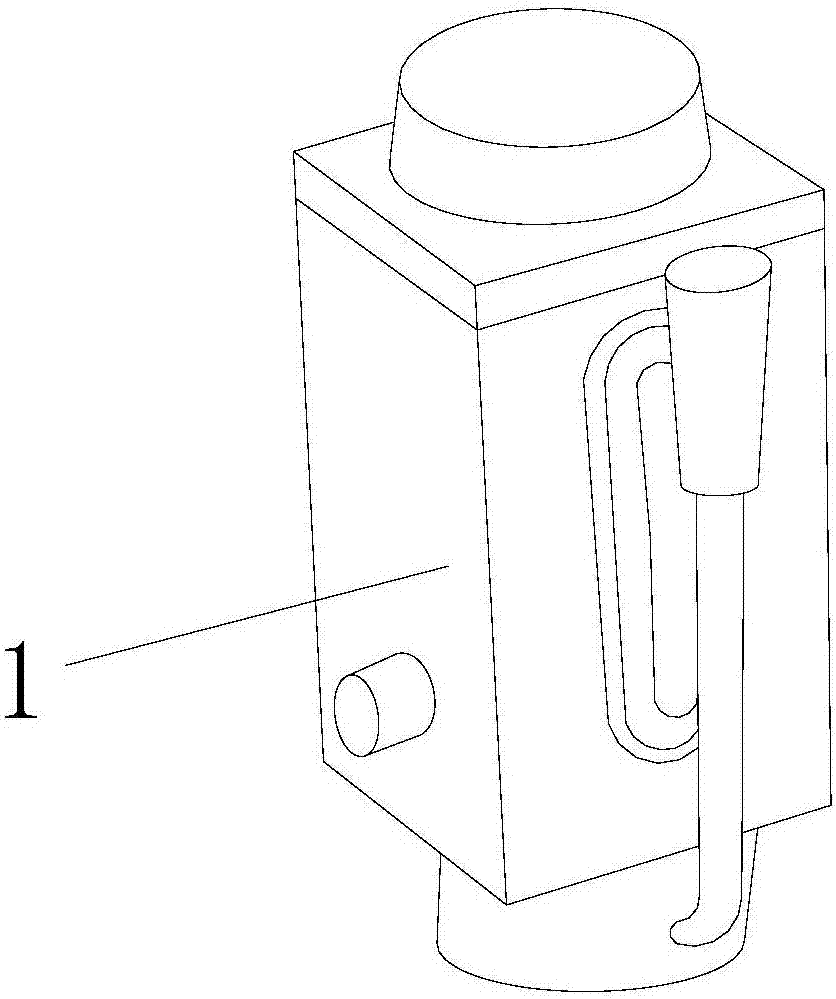

[0021] see Figure 1-Figure 3 , the present invention provides a technical solution: an OSB wood planer, the structure of which includes a speed governor 1, a bottom box 2, a motor 3, a workbench 4, a telescopic clamp 5, a planer main body 6, and an arched frame 7 , the driver 8, the control box 9, the workbench 4 is a cuboid structure with a hard outer wall and a hollow interior, the bottom surface and the top surface of the bottom box 2 are movably connected by welding and form a T shape, and the height of the workbench 4 is 8cm. The arched frame 7 is N-shaped with a hard outer wall and a hollow inner side. The bottom surface is arranged on the top surface of the bottom box 2 and forms a mouth shape. The height of the arched frame 7 is 35cm-45cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com