Adjustable welding clamp device

A welding fixture and adjustable technology, applied in the field of tooling and fixtures, can solve the problems of inability to locate and adjust the welding position, fail to achieve the pass rate of the shock absorber, increase the difficulty of welding, etc., to achieve convenient positioning and adjustment, convenient assembly, The effect of reducing the difficulty of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

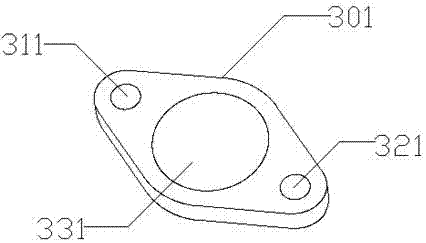

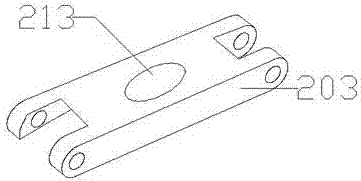

[0012] Such as Figure 1 ~ Figure 3 As shown in the structural diagram of the present invention, an adjustable welding fixture device includes a base 1, a welding adjustment clamping mechanism 2 and a shock absorber 3, and the welding adjustment clamping mechanism 2 is arranged above the base 1 The welding adjustment clamping mechanism 2 includes a first mechanical arm 201, a second mechanical arm 202, a support 203, a lifting device 204 and an adjustment mechanism 205; the adjustment mechanism 205 includes a pressure rod 215 and a regulator 225; The shock absorber 3 includes a flange 301 and a shock absorber body 302; the flange 301 is provided with a first fixing hole 311, a second fixing hole 321 and an assembly hole 331; the shock absorber body 302 passes through the assembly The hole 331 is connected to the flange 301; the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com