Preparation method and applications of porous carbon environment restoration material

A technology of environmental remediation and porous carbon, which is applied in the field of environmental remediation to achieve the effects of easy-to-obtain materials, stable performance, and high carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

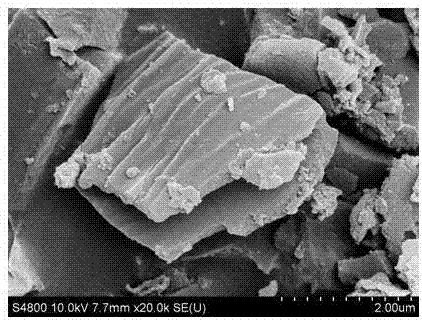

[0052] 1. Preparation of environmental remediation materials: Pour the dead leaves of Typha grass into a porcelain boat for compaction, heat them in a tube furnace at 600°C for 3 hours under ammonia gas, and take them out after cooling down to room temperature to obtain Typha grass carbon.

[0053] Then, the cattail grass carbon, thiourea and ammonium borate were mixed and ball-milled at a mass ratio of 2:5:1 to obtain a crude porous carbon environmental restoration material.

[0054] Add ethanol and H 2 O is washed to obtain the high-quality goods of porous carbon environmental restoration materials.

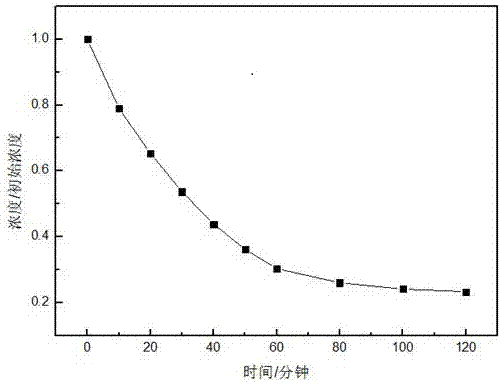

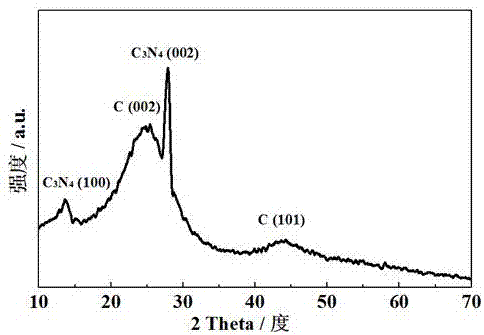

[0055] Further, obtain the XRD patterns of the porous carbon environmental restoration materials, such as figure 1 shown.

[0056] figure 1 In , g-C is generated around 13° 3 N 4 (100) peak, g-C is generated around 27° 3 N 4 (002) peak, it can be seen that the cattail carbon will be ground with thiourea and ammonium borate to produce g-C 3 N 4 . It shows that the meth...

Embodiment 2

[0063] 1. Preparation of environmental remediation materials: Pour the dead leaves of Typha grass into a porcelain boat for compaction, heat them in a tube furnace at 700°C for 3 hours under ammonia gas, and take them out after cooling down to room temperature to obtain Typha grass charcoal.

[0064] Then the cattail grass carbon was mixed with thiourea and ammonium borate at a mass ratio of 2:6:1 and ball-milled for 7 hours to obtain a crude porous carbon environmental restoration material.

[0065] Add ethanol and H 2 O is washed to obtain the high-quality goods of porous carbon environmental restoration materials.

[0066] 2. Application 1: Add the prepared restoration material into a container containing heavy metals or (and) organic polluted wastewater. The mass ratio of material to wastewater is 1:5000. Stir directly for 2 hours to absorb and degrade heavy metals or (and) in water. )Organic Pollutants

[0067] 3. Application 2: Add the prepared repair material to the s...

Embodiment 3

[0072] 1. Preparation of environmental remediation materials: Pour the dead leaves of Typha grass into a porcelain boat for compaction, heat them in a tube furnace at 800°C for 3 hours under ammonia gas, and take them out after cooling down to room temperature to obtain Typha grass charcoal.

[0073] Then the cattail grass carbon was mixed with thiourea and ammonium borate at a mass ratio of 2:7:1 and ball-milled for 8 hours to obtain a crude porous carbon environmental restoration material.

[0074] Add ethanol and H 2 O is washed to obtain the high-quality goods of porous carbon environmental restoration materials.

[0075] 2. Application 1: Add the prepared restoration material into a container containing heavy metals or (and) organic polluted wastewater. The mass ratio of material to wastewater is 1:6000. Stir directly for 2 hours to absorb and degrade heavy metals or (and) in water. )Organic Pollutants.

[0076] 3. Application 2: Add the prepared repair material to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com