Automatic filter element replacement type flue gas desulfurization device

A technology for automatic replacement and desulfurization device, which is applied in the field of mechanical devices and can solve the problems of uneven local desulfurization, long time consumption, and low desulfurization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

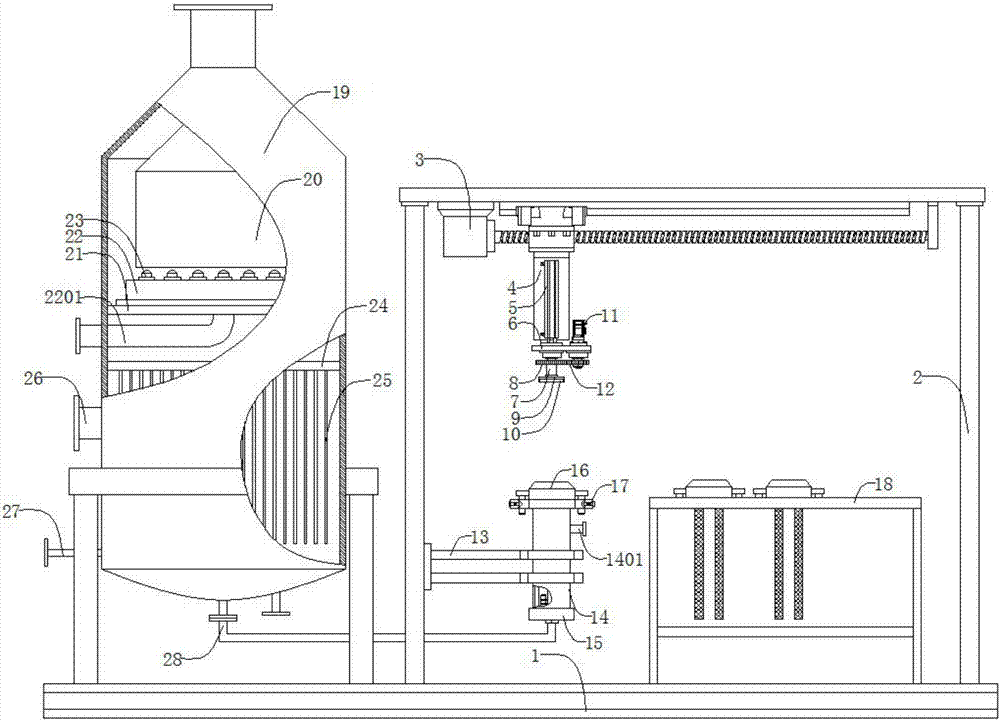

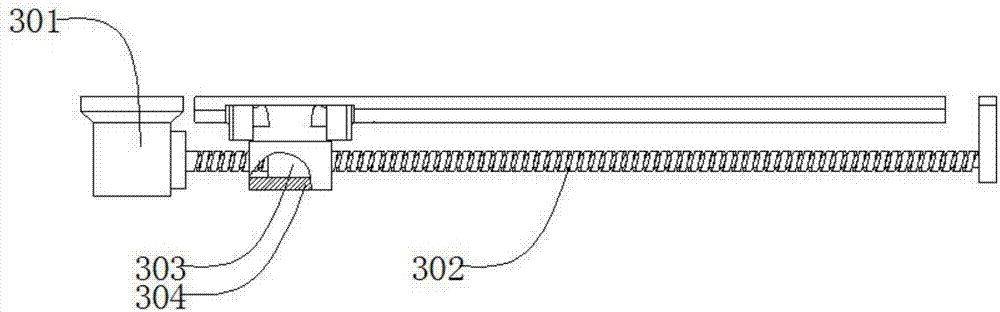

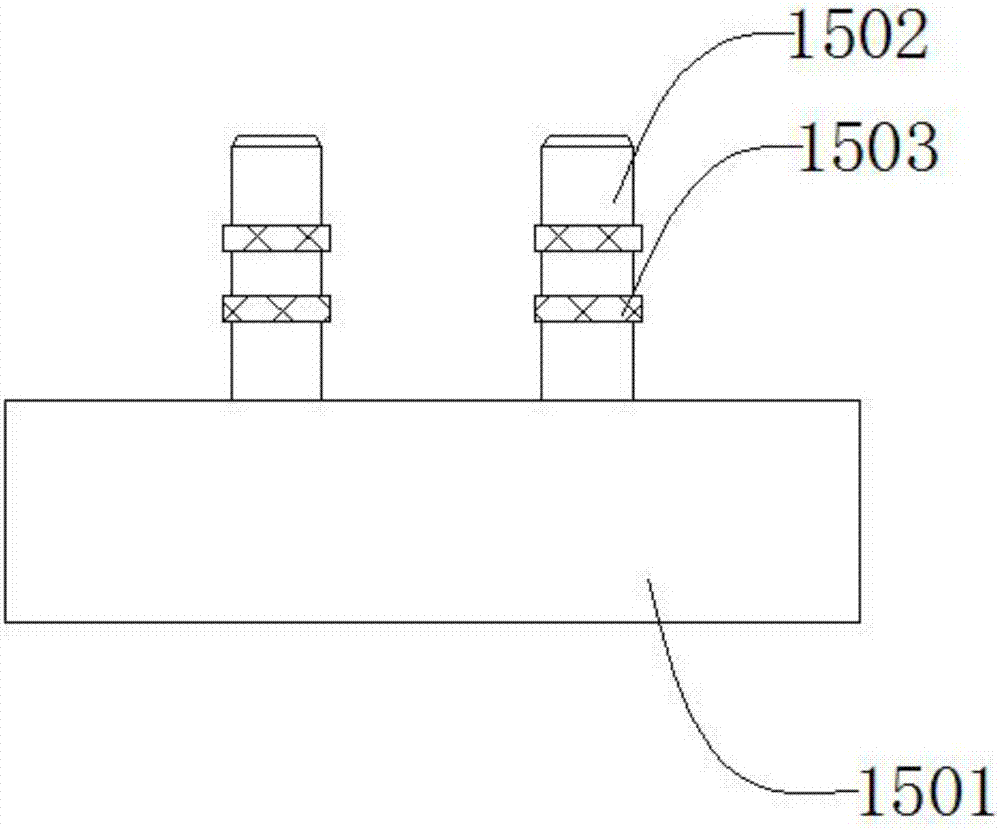

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a flue gas desulfurization device with automatic replacement of filter elements includes a base 1, a bracket 2, a feed mechanism 3, a bracket 4, a cylinder 5, a push plate 6, a rotating shaft 7, a first gear 8, a lock 9, and The lock head 9 is symmetrically arranged with two magnets 10, a first servo motor 11, a second gear 12, a fixed frame 13, a cylinder body 14, a liquid separation mechanism 15, a filter element mechanism 16, and uniformly arranged along the cylinder body 14. The locking mechanism 17, the placement frame 18, the tank body 19, the diffusion pipe 20, the support plate 21, the water tank 22, and the number of atomizing nozzles 23 evenly distributed along the water tank 22 are not less than 2 pieces. , a partition 24, an intubation tube 25, an air outlet pipe 26, a liquid inlet pipe 27, and a liquid discharge pipe 28 uniformly distributed along the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com