Movable-robot-type liquid metal printing device and method

A liquid metal, robotic technology, applied in the field of circuit printing, which can solve the problems of complex use process, limited design size of printed circuit size equipment, and inability to be fed into printing equipment by non-destructive means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

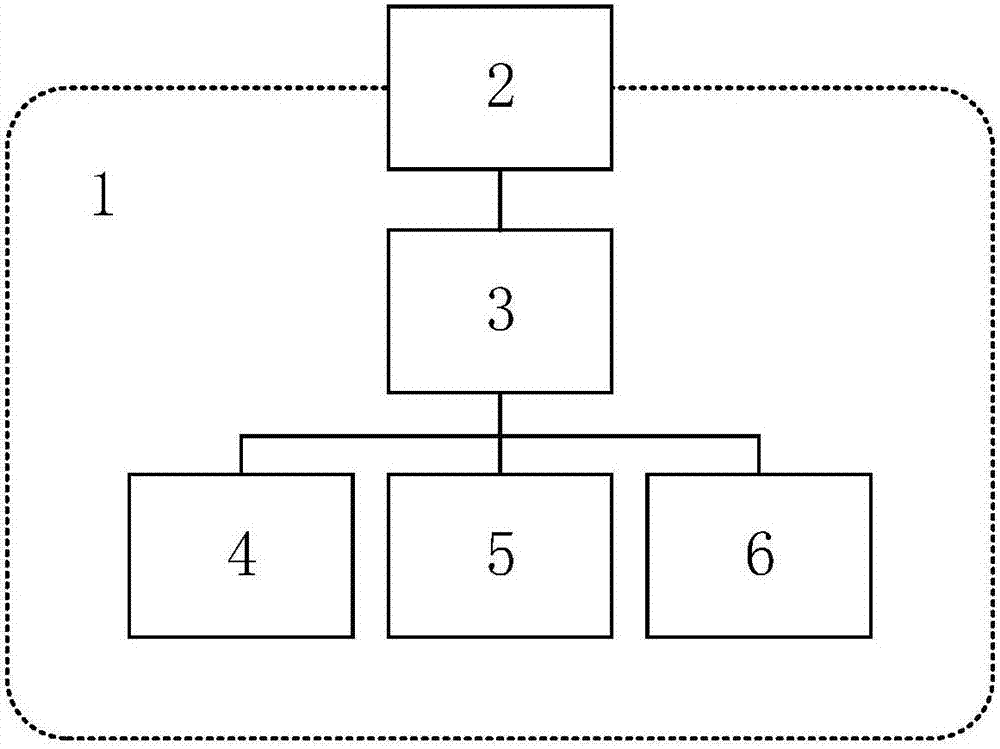

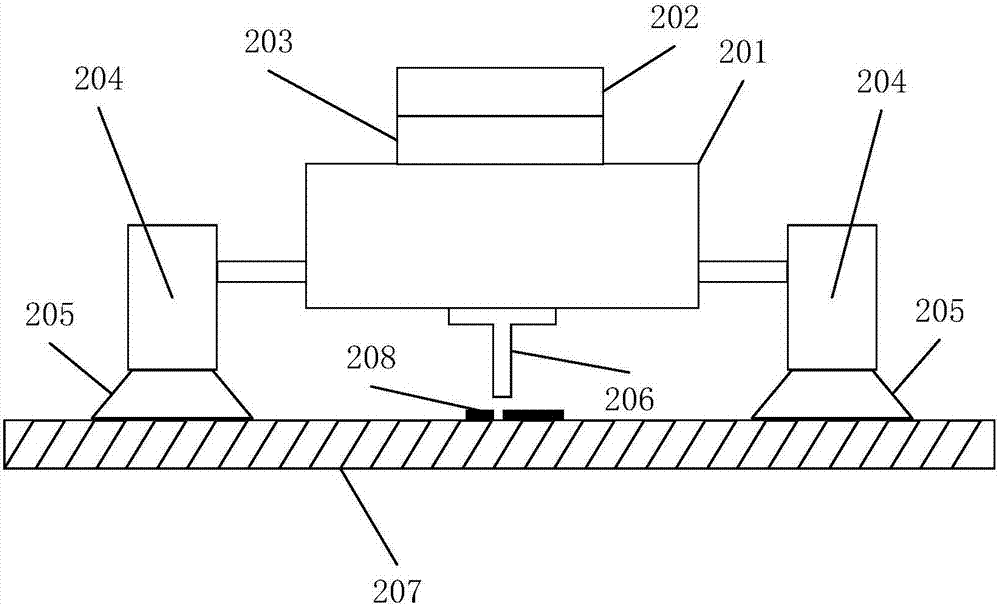

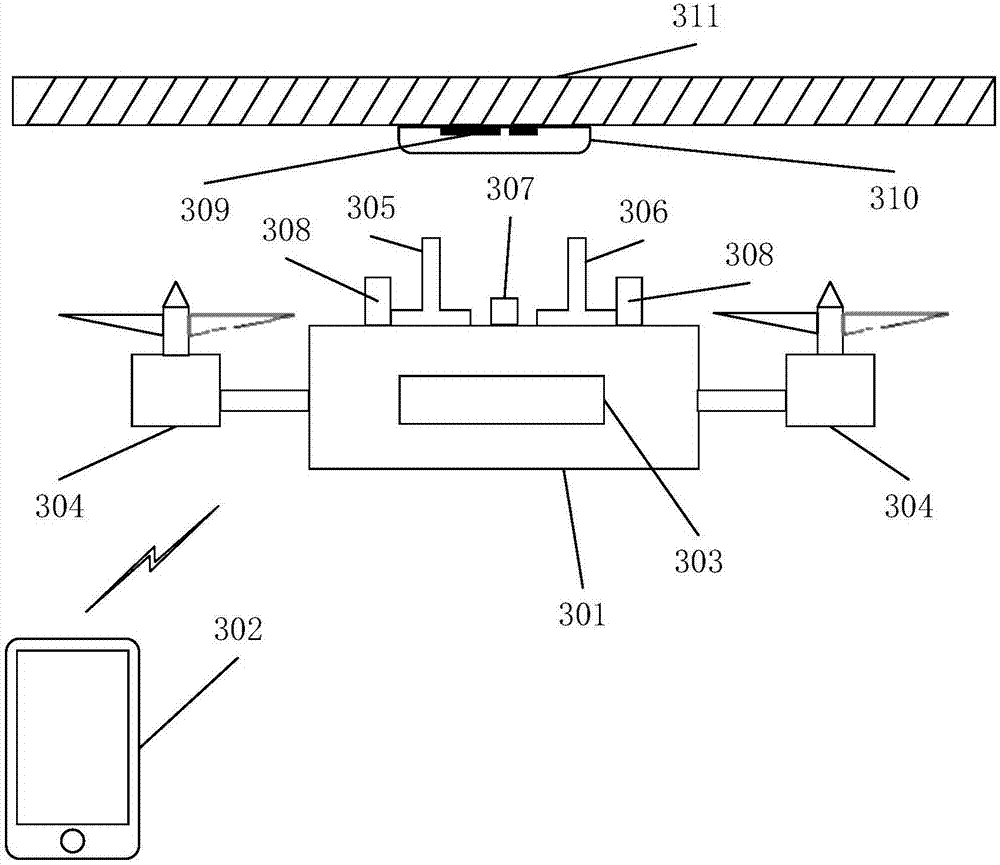

[0033] Mobile robotic liquid metal printing devices, such as figure 1 As shown, the device includes a control unit 2, a drive unit 3, a moving unit 4, an attaching unit 5, and a printing unit 6; the control unit is used to obtain and analyze circuit files and related configuration files to obtain printing circuits, according to the The printing circuit generates a control command, sends the control command to the drive unit, and receives a feedback signal from the drive unit. The driving unit is used to receive the control instruction sent by the control unit and convert it into a moving instruction, an attaching instruction and a printing instruction of the moving unit, the attaching unit, and the printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com