Capacitive touch screen and gluing method thereof

A capacitive touch screen and bonding technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problem of high defects, achieve the effect of improving production yield, facilitating deformation, and improving bubble problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 of the present invention describes a capacitive touch screen bonding method, the method comprising:

[0037] Step 1. Apply an OCA optical adhesive layer 21 on the surface of the film sensor 2 . The OCA optical adhesive layer 21 is pasted on the surface of the film material sensor 2 to facilitate bonding of the film material sensor 2 and the cover glass 1 in subsequent steps. And OCA optical glue has the characteristics of colorless and transparent, light transmittance over 90%, and good bonding strength. Therefore, using OCA optical glue can not only make the film material sensor 2 and the protective glass 1 bond firmly, but also will not affect the touch screen. performance without affecting its display.

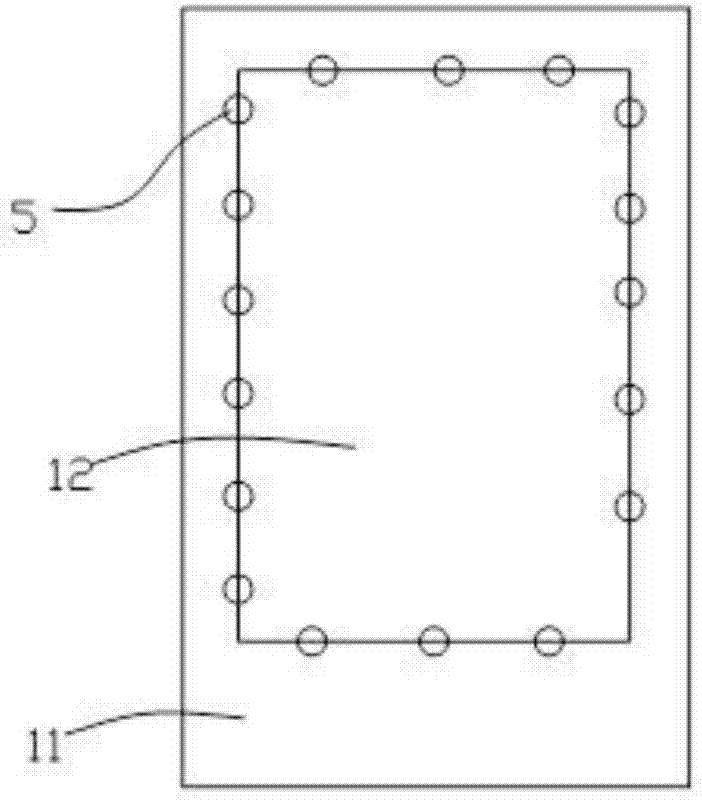

[0038] Step 2. Open a hole 5 in the thickness direction of the film sensor 2 with the OCA optical adhesive layer 21 attached in step 1, so that one end of the through hole 5 is in the ink level difference area 3 . Bubbles will inevitably occur when the...

Embodiment 2

[0052] Embodiment 2 of the present invention describes a capacitive touch screen, which includes:

[0053] The lower surface of the OCA optical adhesive layer 21 is attached to the film sensor 2 , and the upper surface of the OCA optical adhesive layer 21 is attached to the lower surface of the ink layer 11 on the back of the protective glass. The film sensor 2 realizes the touch control of the touch display product, and the OCA optical adhesive layer 21 is used to bond the film sensor 2 and the ink layer 11 on the back of the protective glass, and the ink layer 11 on the back of the protective glass can be used to display the product. Various colors required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com