Sputtering target device for system-level ignition test of electric propulsion spacecraft

An ignition test and spacecraft technology, which is applied in jet engine testing, gas turbine engine testing, etc., can solve the problems of few ignition tests, short ignition duration of electric thrusters, and public reports of sputtering target design plans, so as to reduce the amount of sputtering. The effect of radiation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following introduces specific embodiments as the content of the present invention, and the content of the present invention will be further clarified below through specific embodiments. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention and should not be construed as limiting the scope of the present invention.

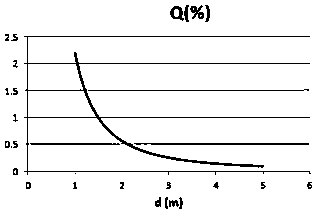

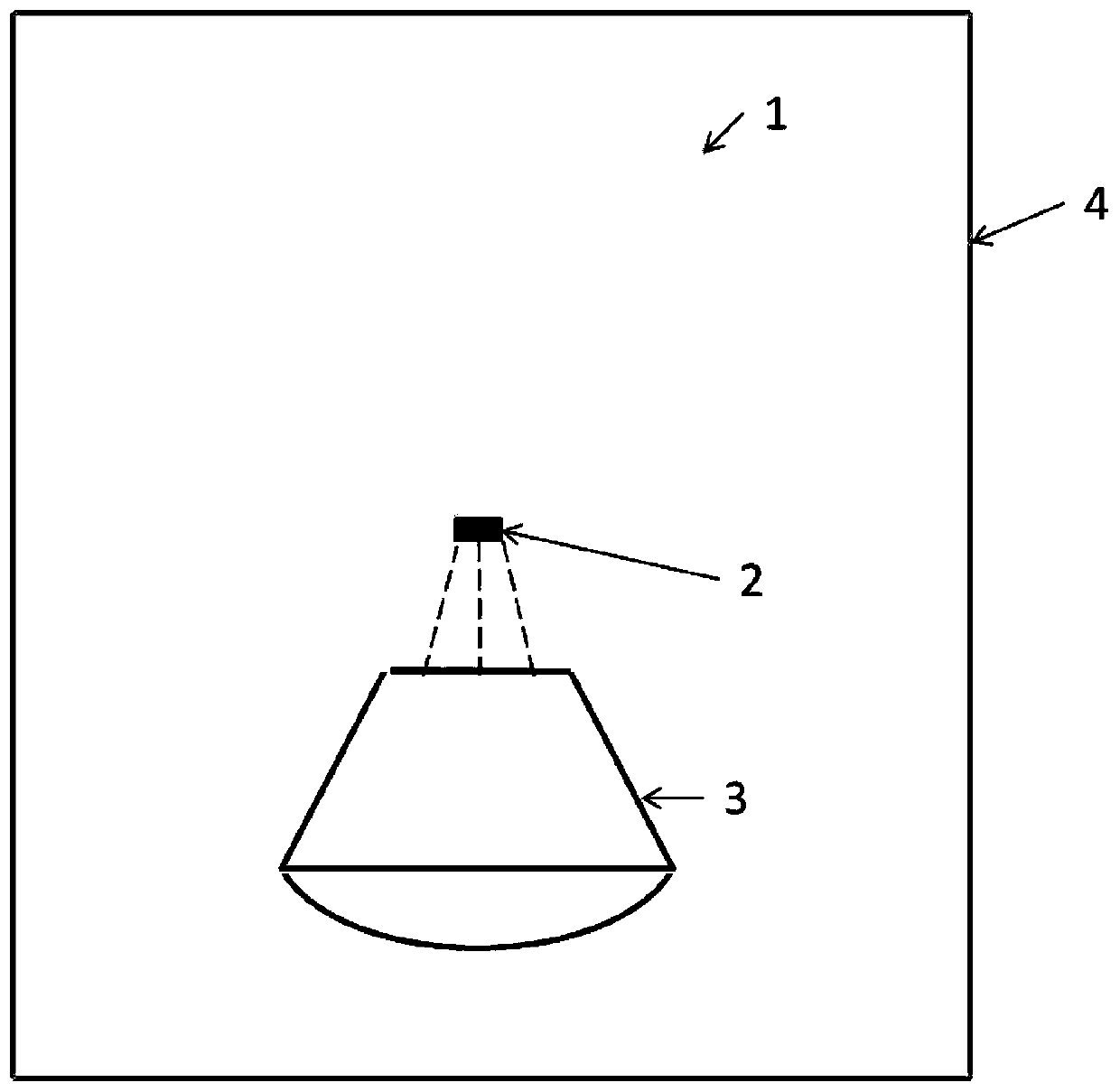

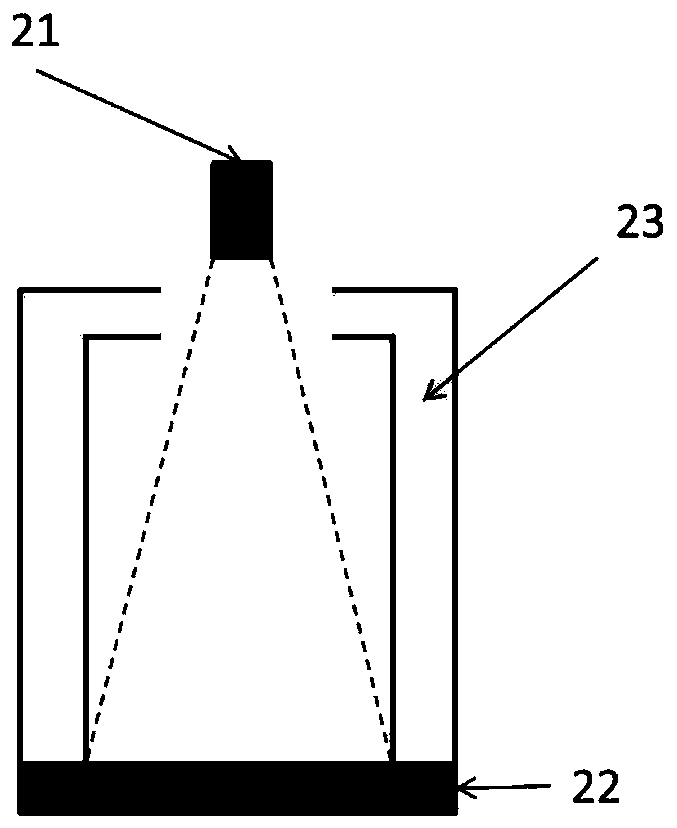

[0034] refer to figure 2 , the device of the present invention is facing the nozzle of the electric thruster 21 and is coaxial with the thruster. In order to achieve the effect of reducing sputtering pollution, the larger the target surface and the farther away from the thruster, the better, but the space left for the thruster sputtering target during the whole star test is limited, so a suitable distance must be determined first. Assuming that the distance between the center of the main target and the center of the thruster nozzle is d, in the case of vertical incidence of particles, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com