Sleeve grouting warehouse sealing tool for fabricated shear wall

A sleeve grouting and shear wall technology, which is applied in the direction of construction and building structure, can solve the problem that it is difficult to accurately delineate the arc groove-shaped sealing surface, the molding effect of the sealing surface is not beautiful, and the quality of the splicing gap can be solved. Defects and other problems, to ensure convenience and standardization, convenient glue sealing and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

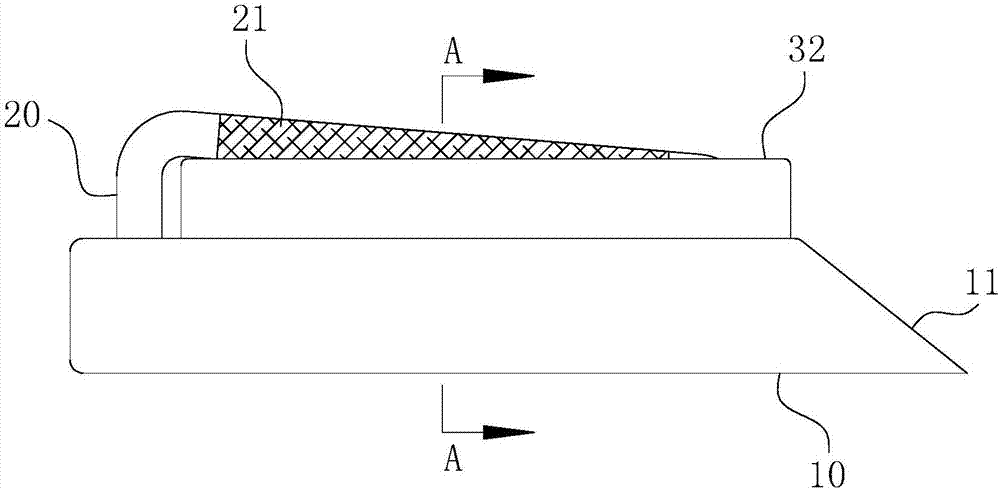

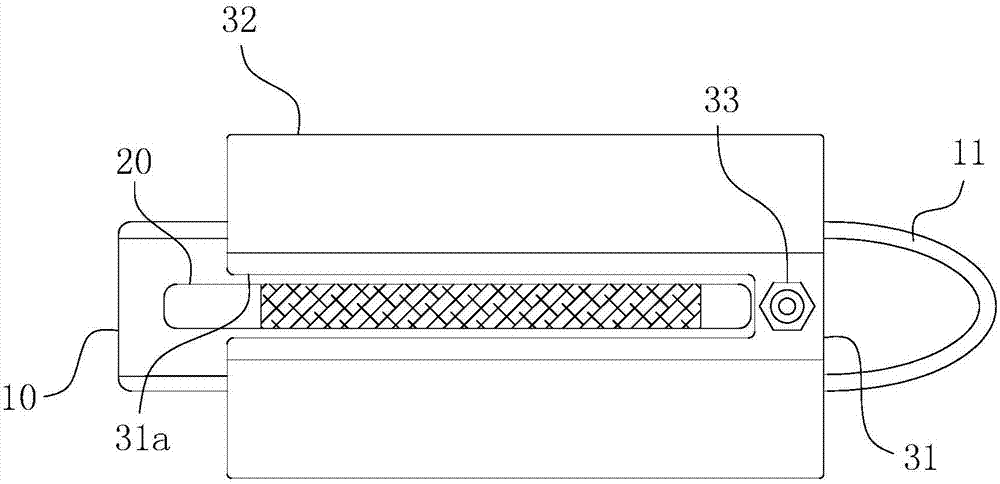

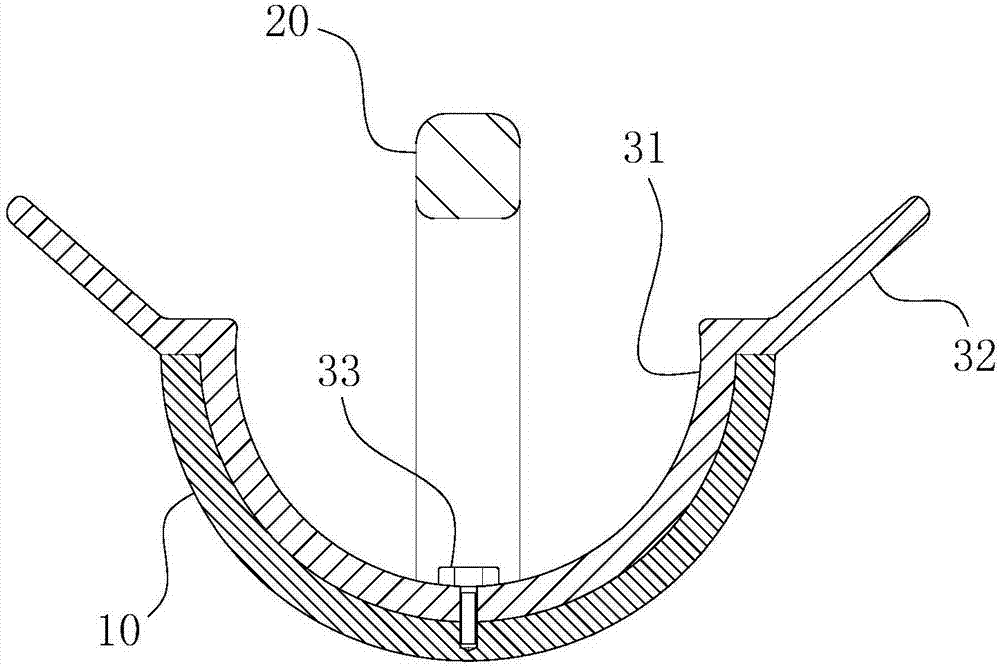

[0023] For ease of understanding, the attached Figure 1-3 , the concrete structure and working mode of the present invention are further described as follows:

[0024] The specific structure of the present invention refers to Figure 1-3 As shown, its main structure is composed of a closed arc plate 10, a handle 20, and a guide pendant. Wherein: the closed warehouse arc plate 10 may be considered to be made of an arc-shaped steel plate, and beveled at the front end of the closed warehouse arc plate 10 to form a slope 11 . The slope surface 11 can scrape the sealing mortar very well, so that the sealing mortar can be filled into the gap between the wallboards more conveniently and quickly. At the same time, a handle 20 made of Ф6mm steel bars is arranged vertically upward along the inner arc surface of the sealing arc plate 10, so that the user can hold and operate the sealing arc plate 10 to perform the corresponding sealing surface forming operation . The handle 20 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com