Hosiery knitter sinker cap controller

A technology of raw hood and controller, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of slow slider response speed, broken needles, defective products, etc., and achieve short displacement time and easy adjustment. , the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

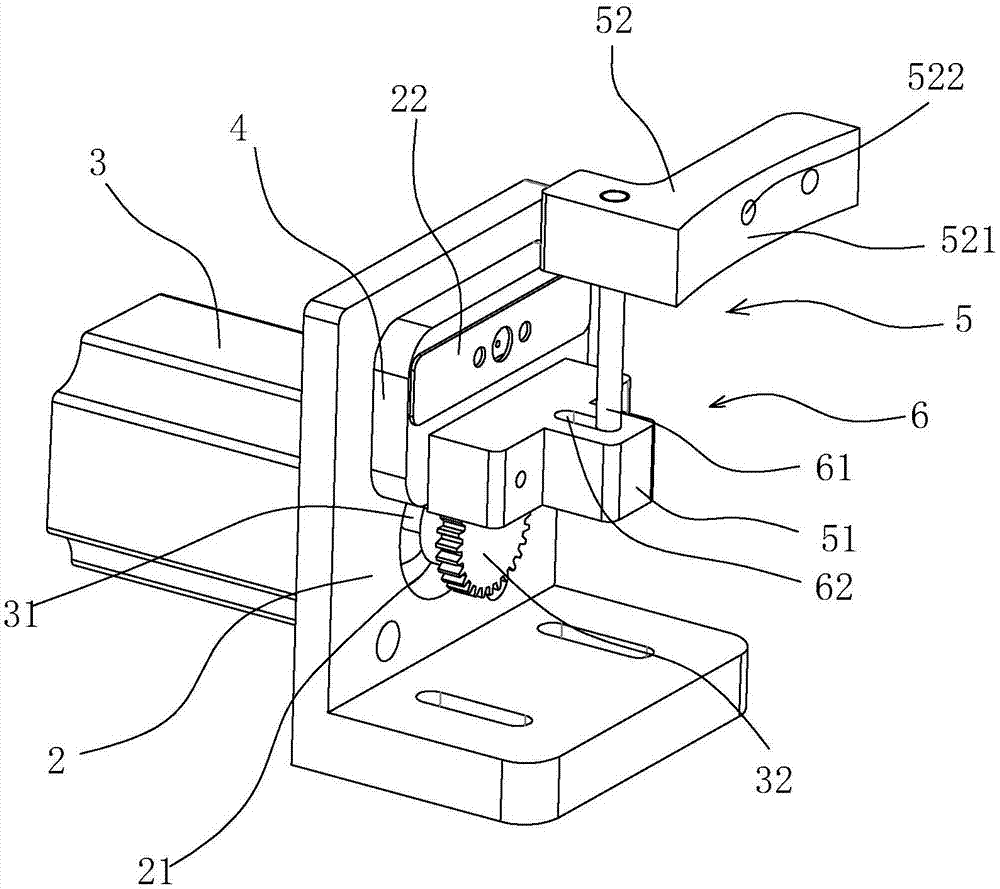

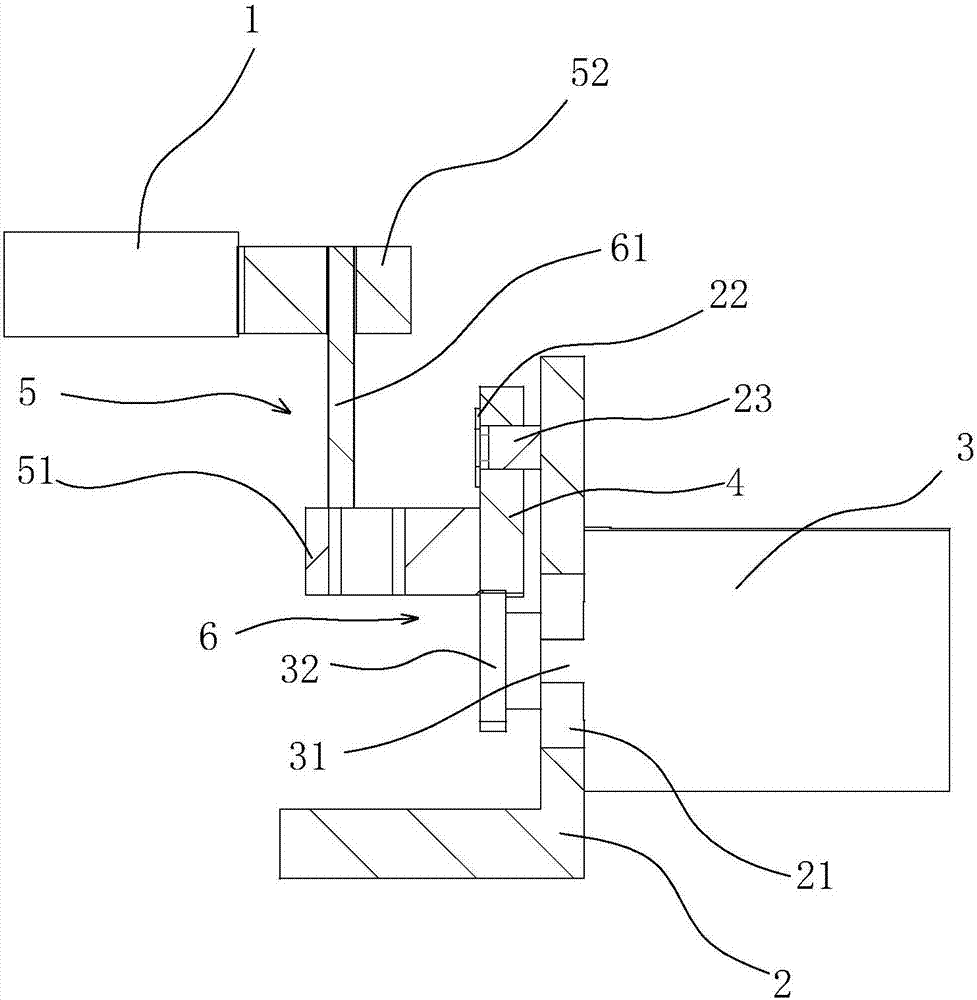

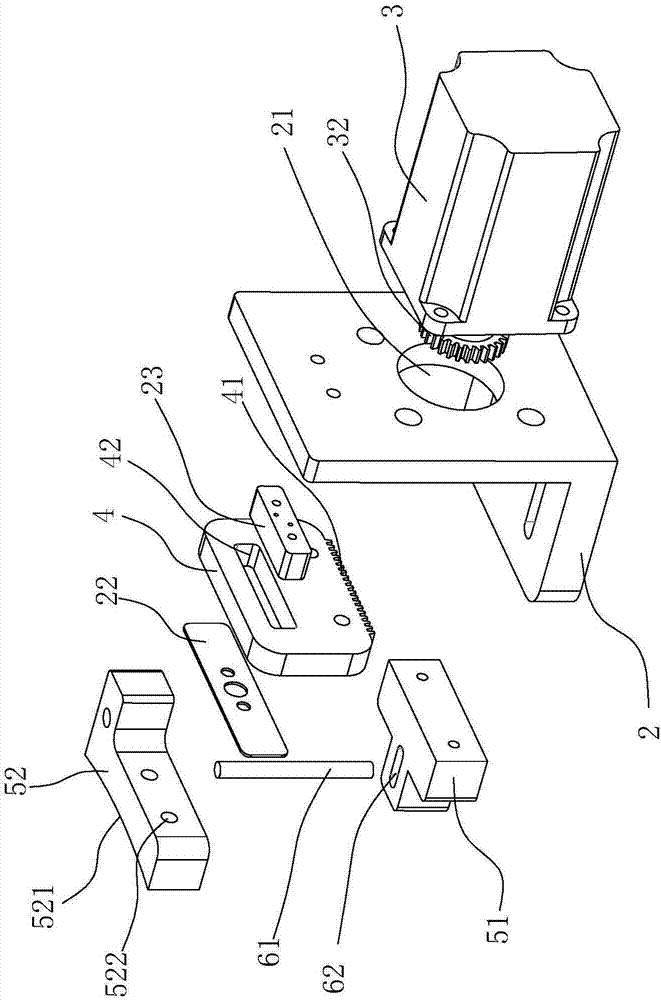

[0023] Such as Figure 1-2 As shown, a sock knitting machine shredder controller includes a base 2 and a translation slider 4 arranged on the periphery of the shredder 1, and a controllable rotary driver 3 is fixedly installed on the base 2, and the The controllable rotary driver 3 is provided with a rotating shaft 31 and is connected with a driving gear 32 on the rotating shaft 31. The driving gear 32 is engaged with the rack 41 arranged on the translation slider 4, and the translation slider 4 is connected to There is a transmission mechanism 5 and is connected with the Sinker cover 1 through the transmission mechanism 5 to control the circumferential swing of the Sinker cover 1 .

[0024] The controllable rotary driver 3 drives the driving gear 32, and the driving gear 32 drives the rack 41 to drive the translation slider 4 to make a linear motion, and the translation slider 4 converts the linear motion into a rotary motion through the transmission mechanism 5 and drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com