Novel roller quenching water-spraying device

A technology of water spraying device and roll, applied in quenching device, furnace type, heat treatment equipment, etc., can solve the problems of large quenching cracking tendency and high total alloy amount, and achieve the advantages of reducing internal stress, facilitating disassembly, and reducing the risk of quenching cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

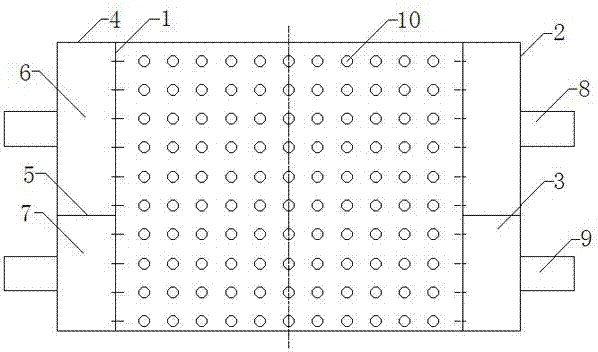

[0016] Such as figure 1 Shown: a new type of quenching water spraying device for rolls, the quenching water spraying device includes an inner cylinder 1 for water spraying and an outer cylinder 2 for water supply coaxially arranged, the inner cylinder 1 and the outer cylinder 2 formed between The two ends of the cavity 3 are respectively sealed with end caps 4 and the cavity 3 is separated by a partition plate 5 to form a sealed upper pressure water chamber 6 and a lower pressure water chamber 7 respectively. The axial length in the upper pressure water chamber 6 is the same as The ratio of the axial length of the lower pressure water chamber 7 is 7:3-4, and the upper pressure water chamber 6 and the lower pressure water chamber 7 pass through the upper water inlet pipe 8 and the lower water inlet pipe 9 provided on the outer cylinder 2 and the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com