Special adhesive for foam glass insulation system as well as preparation method and use method of adhesive

A thermal insulation system and foam glass technology, applied in thermal insulation, building components, climate change adaptation, etc., can solve problems such as cracking and bonding failure, achieve excellent water-resistant tensile bonding strength, and increase the economic benefits of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

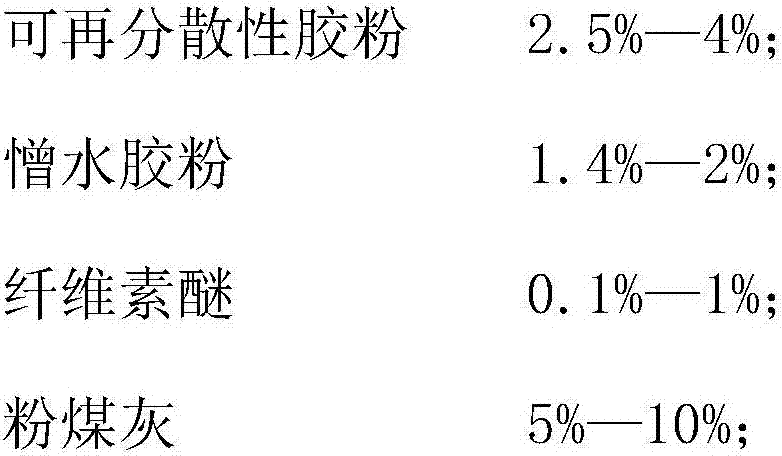

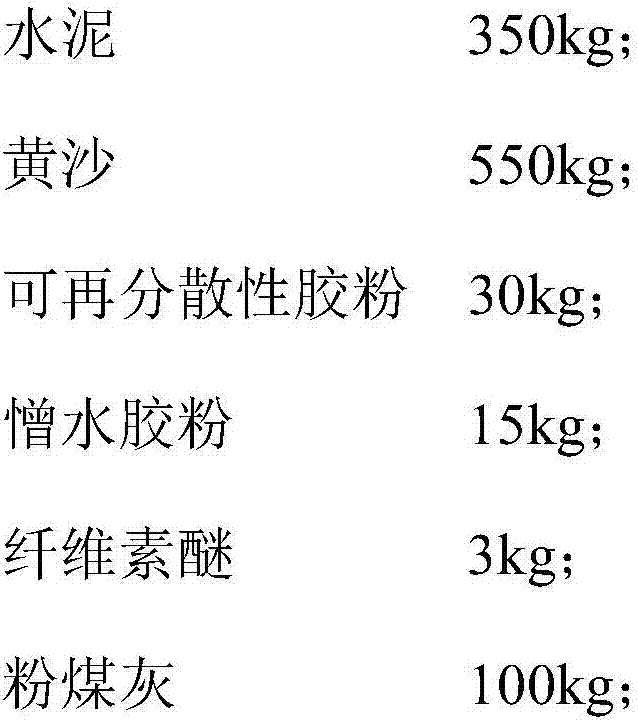

[0036] The special adhesive for foam glass insulation system in this example is prepared from the following raw materials in mass percentage:

[0037]

[0038] The cement is 42.5 cement; the yellow sand is 40-70 mesh dry medium sand.

[0039] In the present invention, the redispersible rubber powder adopts German Wacker 5044N is a kind of vinyl acetate / ethylene copolymer rubber powder that can be redispersed in water. Its glass transition temperature Tg is -7℃, and the minimum film-forming temperature is below 0℃.

[0040] Hydrophobic rubber powder is hydrophobic rubber powder, brand and model: Wacker, Germany 8031H, the minimum film-forming temperature is 0°C. The purpose of adding this rubber powder is to make it repellent to water, which helps to improve the water-resistant tensile bonding strength of the adhesive.

[0041] Because vinyl acetate / ethylene copolymer rubber powder has a high ethylene content, it has a certain degree of flexibility, which is characterize...

Embodiment 2

[0047] In this example, the preparation method of the special adhesive for foam glass insulation system adopts the following preparation steps:

[0048] (1) weigh raw materials by the proportioning in embodiment 1;

[0049](2) Stir the weighed cement and yellow sand for 10 minutes first, use a mixer, and the stirring rate is 120 rpm.;

[0050] (3) Put in redispersible rubber powder, hydrophobic rubber powder, cellulose ether, and fly ash and continue stirring with a mixer for 20 minutes at a stirring rate of 120 rpm; mixing and stirring dry powder adhesive is a very important step in the production process The process requires cement and adhesive materials to be evenly distributed on the surface of the aggregate, only in this way can high-quality adhesive products be obtained;

[0051] (4) Discharge packaging.

[0052] In this example, the mixer adopts DSH double-helix conical mixer.

Embodiment 3

[0054] When in use, mix the special adhesive for foam glass insulation system with water at a mass ratio of 1:0.23, then stir with a hand-held electric mixer for 3-5 minutes to make it even without lumps, stand still for 5 minutes, and then stir for 3-5 minutes.

[0055] Then apply a special adhesive with a thickness of not less than 5mm and an area of not less than 50% of the insulation board on the back of the foam glass, and then stick it on the outer wall of the building's base wall. Before the general adhesive is used, it is necessary to do interface treatment on the base wall surface such as coating interface agent, etc., but the special adhesive in the present invention is characterized in that regardless of the old and new wall surface, as long as the base wall surface is firm, it is not used as special adhesive such as coating interface agent. It is very convenient to handle and use.

[0056] The formula ratio in the present invention has been verified through a lar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com