Solid-liquid mixed material treatment method and device

A technology of solid-liquid mixing and treatment methods, applied in sludge treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of limited reaction rate, uneven reaction, high equipment requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A solid-liquid mixture treatment method, especially suitable for sludge treatment, comprising the following steps:

[0037] 1) Select a suitable release agent according to the characteristics of the material to be processed: the density of the release agent is between the density of the solid phase substance and the liquid phase substance to be separated in the material;

[0038] 2) Add a release agent of 20%-20 times the mass of the material to the material to be treated to form a release agent layer between the solid phase and the liquid phase;

[0039] 3) Use a centrifuge for centrifugal separation;

[0040] 4) The separated solid phase material is dried, the separated liquid phase material is evaporated or membrane separated, and the release agent is recycled;

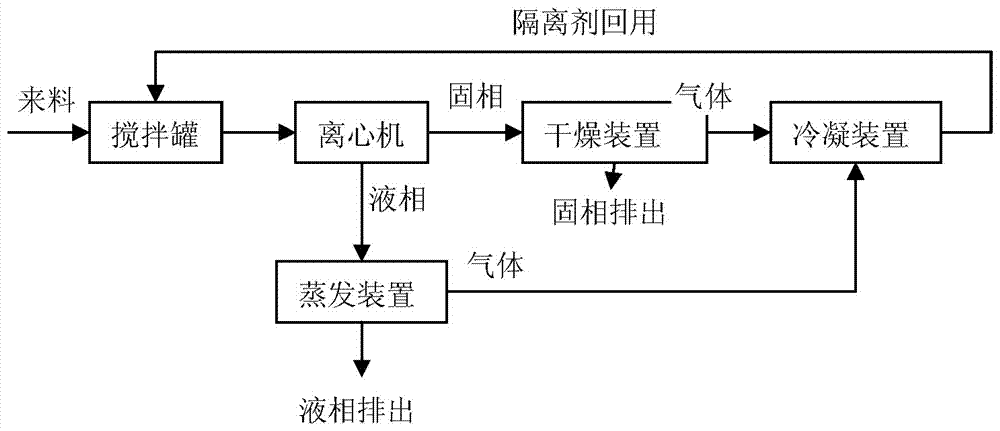

[0041] Step 4) The specific operation method is ( figure 1 ):

[0042] a. Dry the solid-phase material, and steam the spacer out of it. The steamed spacer gas is condensed into a liquid through a condensi...

Embodiment 2

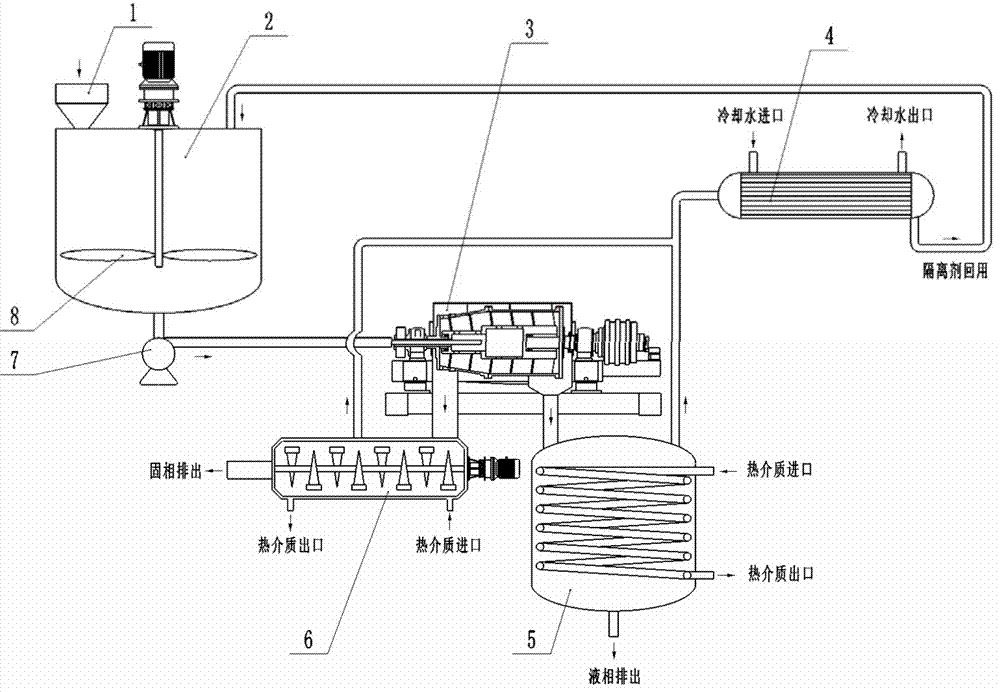

[0065] This embodiment is the equipment used for the treatment method of Embodiment 1, such as figure 2 shown.

[0066] A solid-liquid mixture material processing device, the device includes a stirring tank 2, a mixed liquid delivery pump 7, a centrifuge 3, a condensation device 4, an evaporation device 5, and a drying device 6; the stirring tank 2 is provided with a feed port 1 and the separator inlet, the mixed liquid outlet of the stirring tank is connected to the inlet of the mixed liquid delivery pump through a pipeline, the outlet of the mixed solution delivery pump is connected to the inlet of the centrifuge through a pipeline, and the solid phase outlet of the centrifuge is connected to the outlet of the drying device The inlet, the liquid phase outlet of the centrifuge is connected to the liquid inlet of the evaporator; the gas outlet of the drying device is connected to the inlet end of the condensing device through a pipeline; Connect the inlet end of the condensi...

Embodiment 3

[0069] This embodiment is a specific processing case based on Embodiment 1.

[0070] (by mass) The moisture content of Vietnamese phosphate rock slurry samples is 60%, and that of phosphate rock is 40%.

[0071] Add the above-mentioned phosphate rock slurry into the stirring tank, add the spacer carbon tetrachloride which is 1.5 times the mass of the phosphate rock pulp, and fully stir and disperse.

[0072] The phosphate rock slurry is pumped into a decanter centrifuge for solid-liquid separation. The centrifuge speed is selected to be 3000r / min. The phosphate rock slurry is separated into three phases of phosphate rock slurry, carbon tetrachloride, and water. After testing, the moisture content of the phosphate rock after centrifugation is 12.2%. .

[0073] After centrifugation, the phosphate rock is dried to an anhydrous state with very low energy consumption. Liquid phase distillation recovers carbon tetrachloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com