Precision target system for near field target calibration of camera with large field of view and method

A large field of view and camera technology, applied in image data processing, instruments, calculations, etc., can solve problems such as low accuracy, low efficiency, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

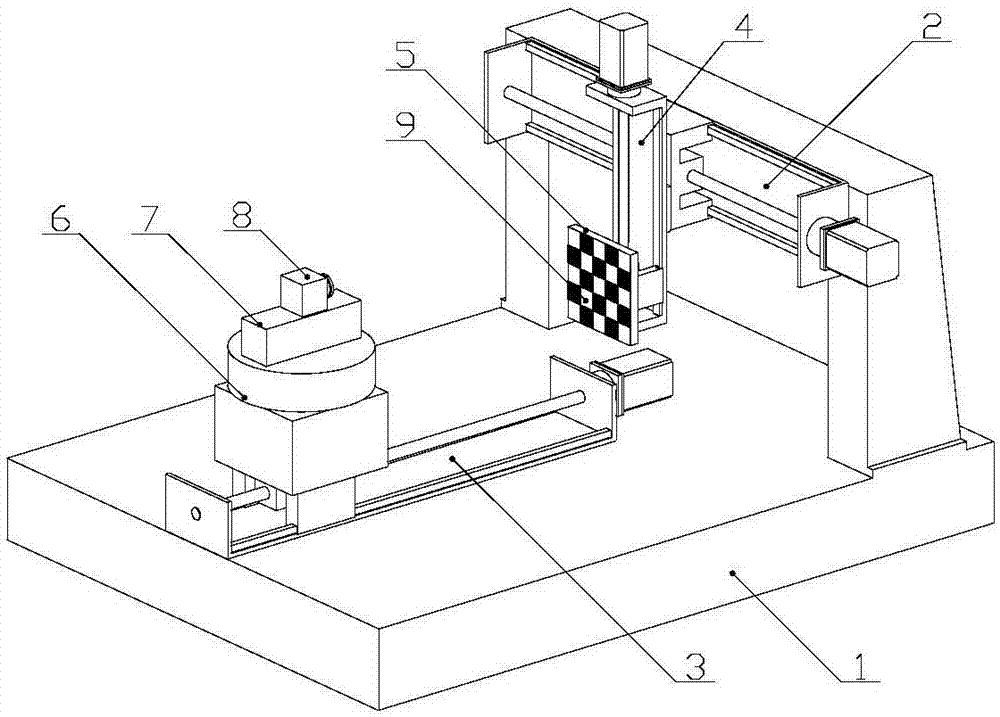

[0029] figure 1 It is a three-dimensional diagram of the precision target system for the near-field calibration of the large field of view camera in this embodiment, including the gantry frame 1, the X-axis motion mechanism 2, the Y-axis motion mechanism 3, the Z-axis motion mechanism 4, the target 5, the turntable 6, Pitch platform 7, camera under test 8, target surface 9.

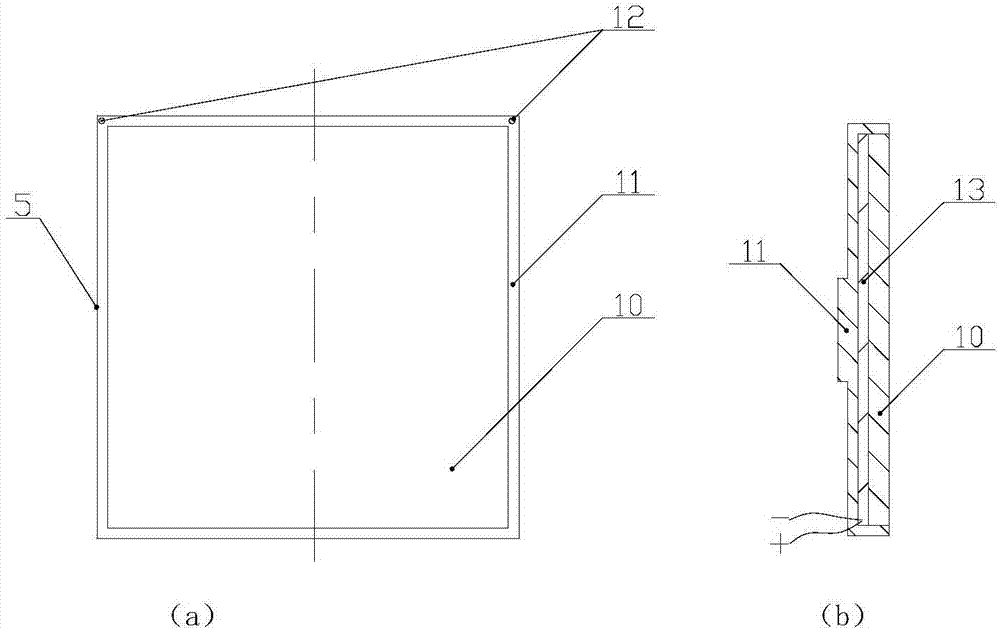

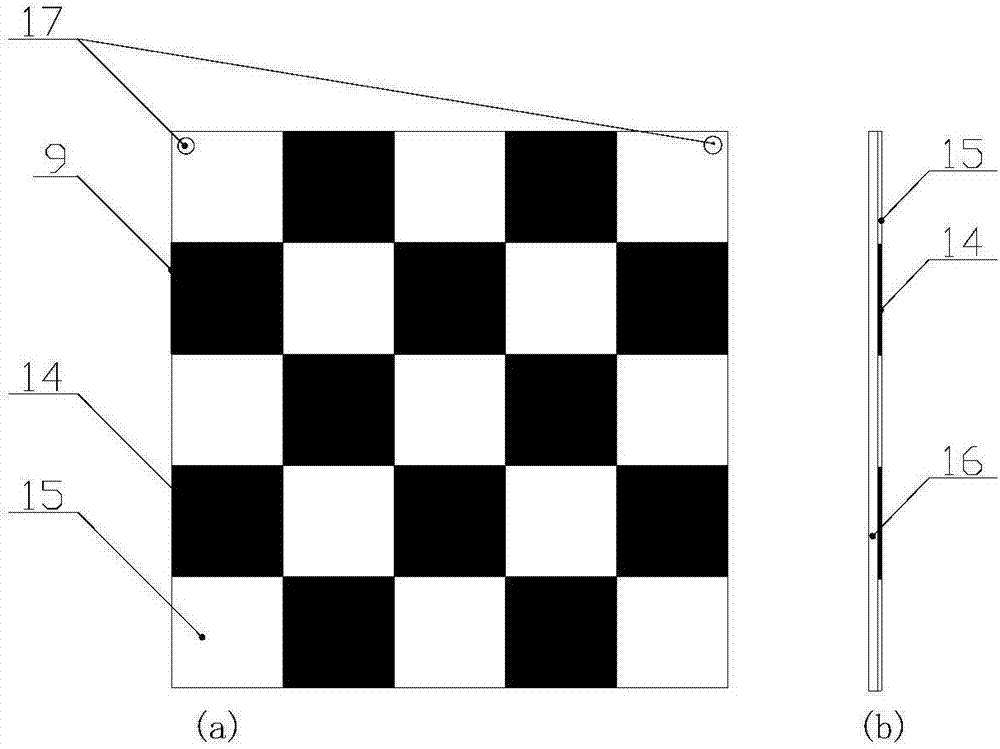

[0030] Among them, the system adopts the gantry frame 1 as the main support, and the base of the gantry frame 1 adopts shock-isolation treatment; the X-axis motion mechanism 2, the Y-axis motion mechanism 3 and the Z-axis motion mechanism 4 adopt high-precision linear motion screw shafts, and two-by-two perpendicular to each other. The target surface 9 is installed on the front of the target 5 , and the gap between them is filled with thermal condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com