Air film type jetting device and extractor hood with same

A range hood and air film technology, which is applied in the field of air film ejection device, can solve the problems of not being able to block the escape of oil fume and cooking environment, and achieve the effect of reducing the escape of oil fume and avoiding the adhesion of oil fume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

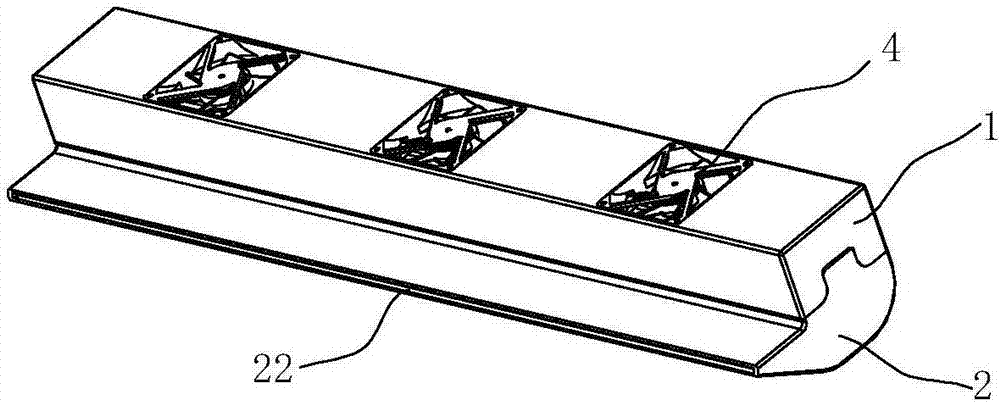

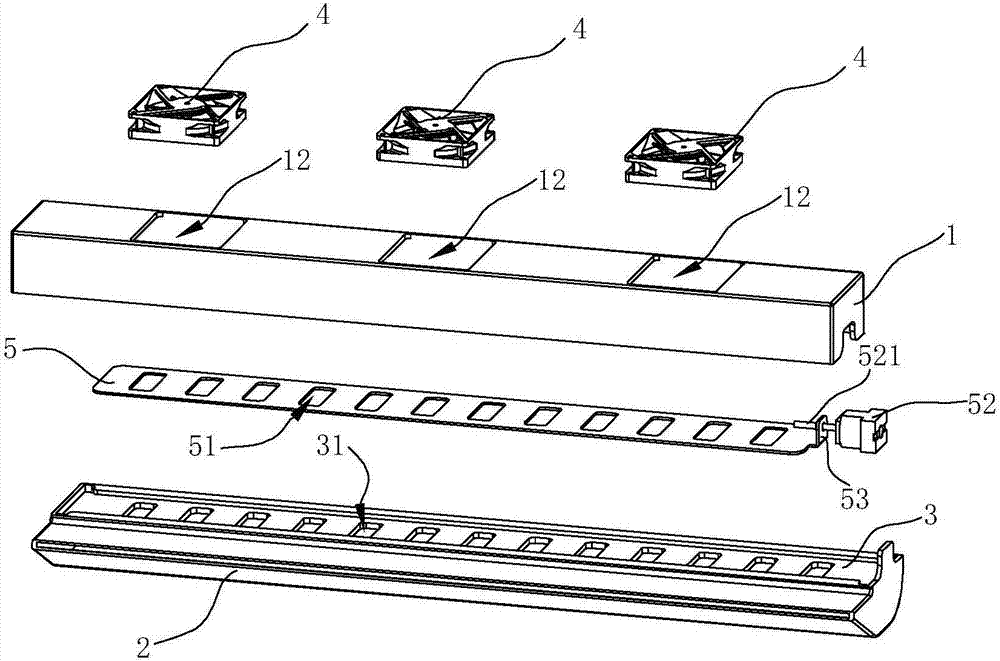

[0030] see Figure 1 to Figure 5 , a kind of air film injection device, comprises the box body that is formed with inner chamber, is provided with a cutoff plate 3 in the inner chamber, divides the inner chamber into the first chamber 11 and the second chamber 21 that communicate with each other, the first The cavity 11 communicates with the outside world, and a fan 4 is arranged therein for sucking the air from the outside into the device, and the second cavity 21 ejects air flow outward. Thus, the first cavity 11 constitutes a dynamic pressure chamber, while the second cavity 21 constitutes a static pressure chamber.

[0031] The partition plate 3 is provided with at least two first ventilation holes 31 arranged side by side and spaced apart in the length direction of the plate, so that the gas sucked into the first cavity 11 by the fan 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com