Combined steel structure support pile and construction method

A technology of steel structure and supporting piles, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc. The effect of shortening the construction period and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

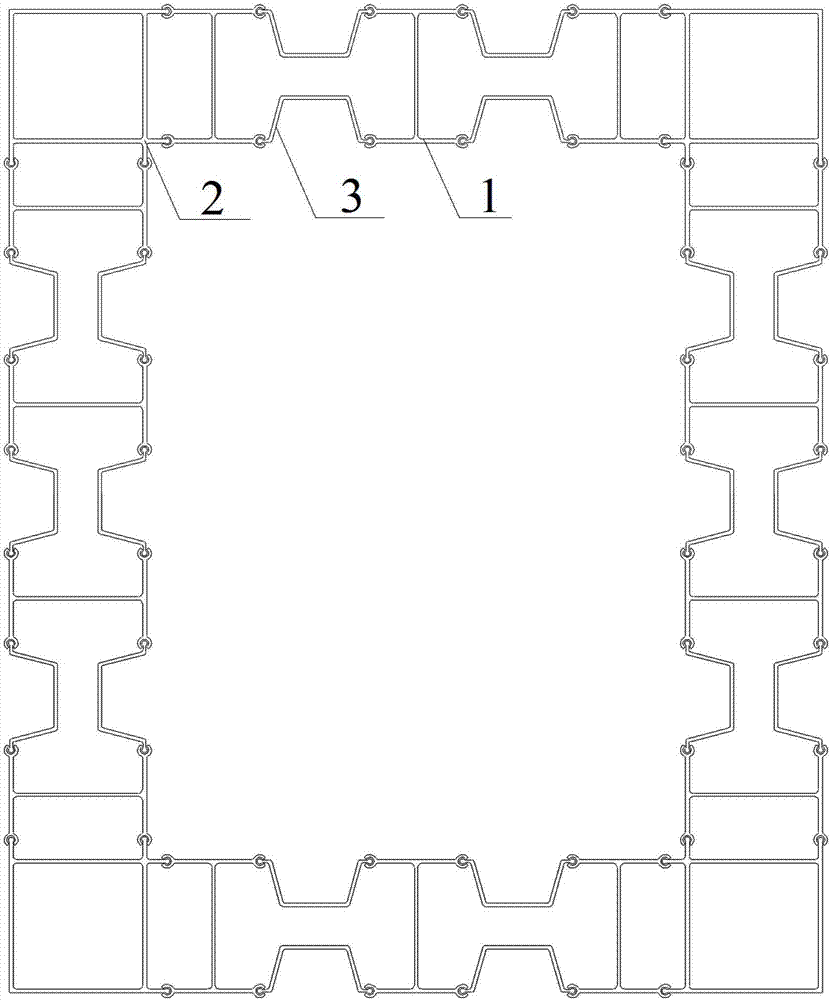

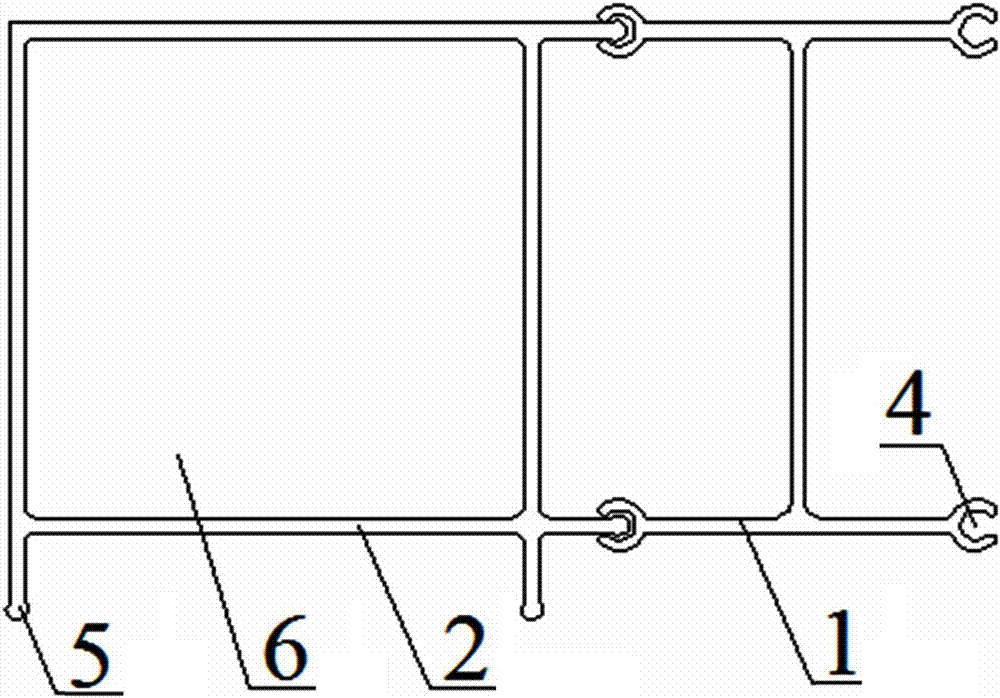

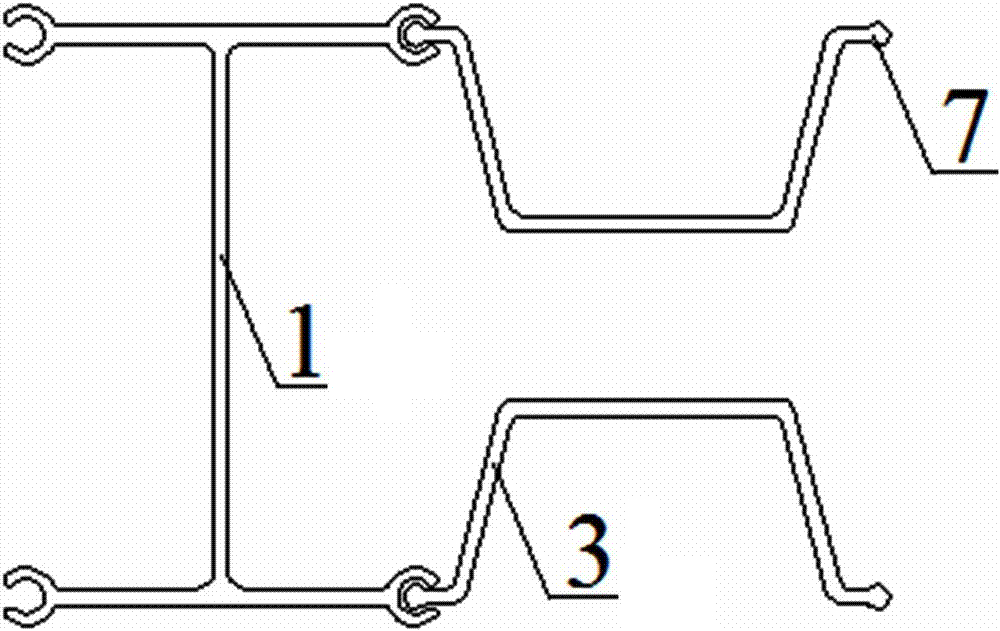

[0050] A combined steel structure support pile and its construction method, which consists of the following parts: (1) H-shaped steel pile, special-shaped hollow steel pile with right-angled sides and U-shaped steel pile, all of which are designed according to the project scale and geological conditions. Conditional calculation determines the specific section size, section material thickness and grade, and then it is manufactured by the factory and then transported to the site or made on site; (2) overall, partial or single root subsidence is used according to geological conditions; when other factors such as geology When the overall subsidence is not possible due to restrictions, single or local subsidence can be subsidence to the predetermined elevation; (3) Excavation of foundation pit earthwork, and subsequent construction of steel purlins, purlin brackets and steel supports, steel purlins, steel supports Bollards and steel support connections such as Figure 7 shown.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com