Fabric non-water dyeing method

A process method and fabric technology, applied in the textile field, can solve problems such as poor dyeing effect and waste of raw materials, and achieve the effects of energy saving, good dyeing effect, and raw material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

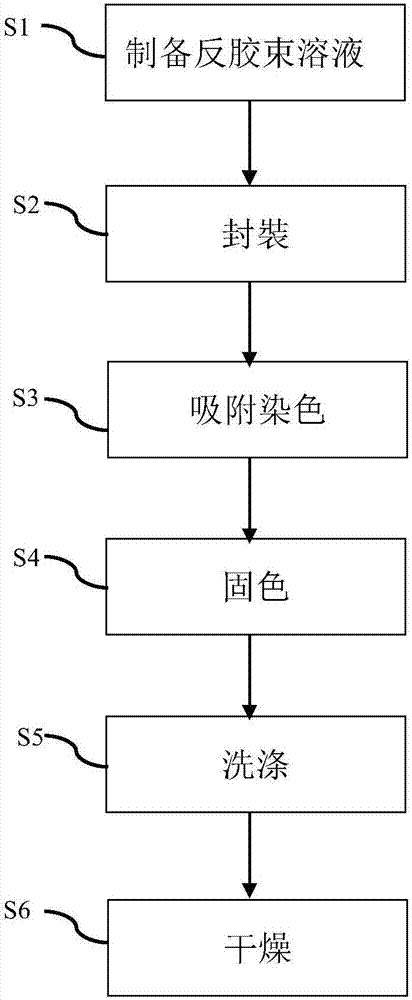

Method used

Image

Examples

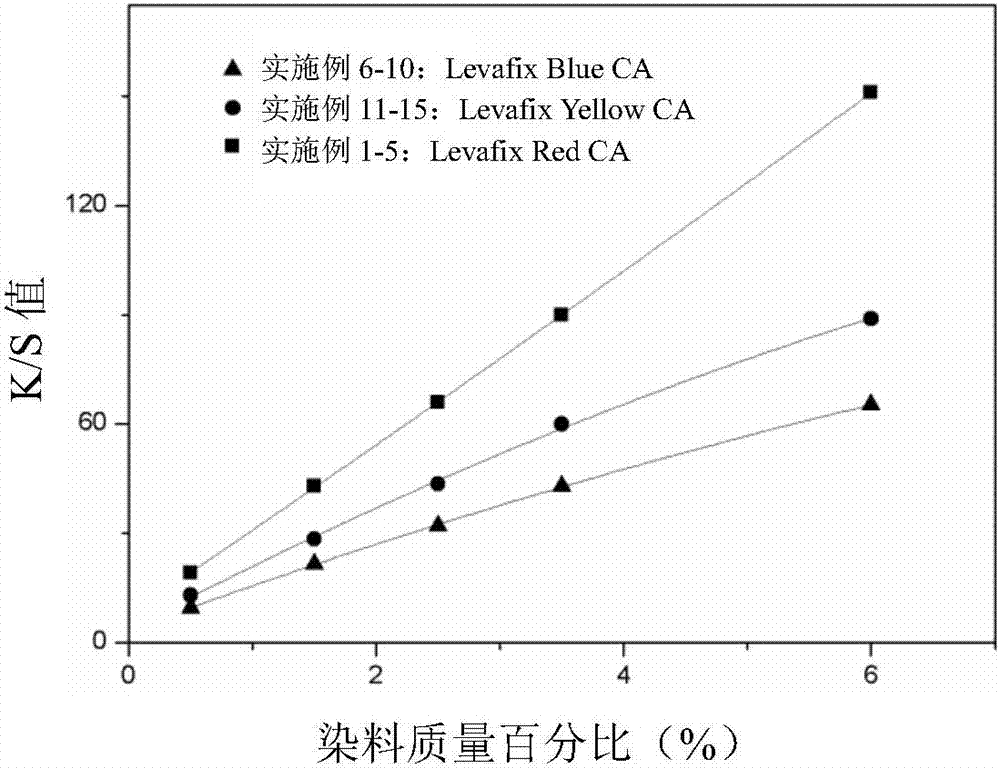

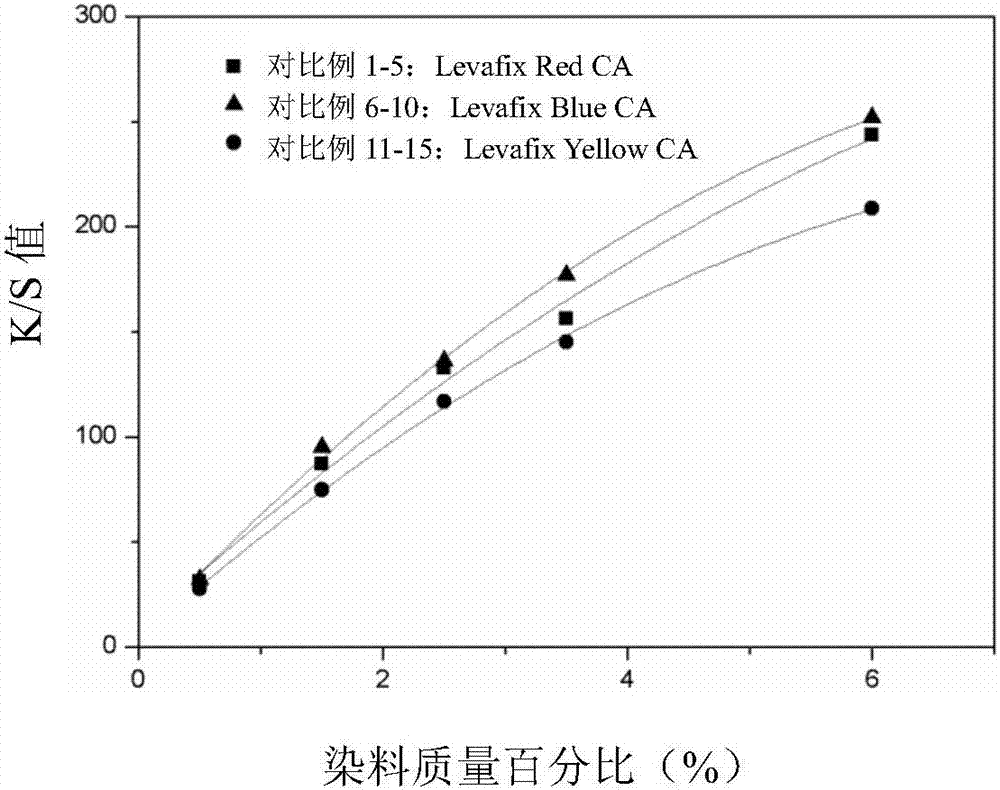

Embodiment 1

[0040] In this embodiment, the nonionic surfactant is polyethylene glycol-12-tridecyl ether, that is, R in the molecular formula 1 for H, R 2 for linear C 13 Alkyl, n is 12. At room temperature, pre-mix 0.0175mol of n-octanol and 0.0025mol of non-ionic surfactant in a beaker by stirring, the ratio is 7:1, and dissolve them in 15ml of n-octane after mixing to make reverse Micellar solution; a certain amount of Levafix Red CA reactive dye is dissolved in a very small amount of water to make 0.5ml of a 5% reactive dye solution by mass percentage, and the reactive dye solution is slowly injected into the reverse micellar solution. After vigorously stirring for 2 minutes at a rotating speed, the solution was clarified to obtain a reactive dye solution encapsulated in reverse micelles, wherein the mass ratio of the reactive dye to 1 gram of fabric was 2.5%; the sample of 1 g of cotton fabric was immersed in a ratio of 1:15 In the reactive dye liquid encapsulated by reverse micell...

Embodiment 2

[0042] In this embodiment, the nonionic surfactant is polyethylene glycol-12-tridecyl ether, that is, R in the molecular formula 1 for H, R 2 for linear C 13 Alkyl, n is 12. At room temperature, pre-mix 0.0156mol of n-octanol and 0.0024mol of non-ionic surfactant in a beaker by stirring, the ratio is 6.5:1, and dissolve in 10ml of n-octane after mixing to make a reverse glue Beam solution; a certain amount of Levafix Red CA reactive dye is dissolved in a small amount of water to make 0.5ml of a 7% reactive dye solution by mass percentage, and the reactive dye solution is slowly injected into the reverse micelles solution. After stirring for 5 minutes, the solution was clarified to obtain a reactive dye solution encapsulated by reverse micelles, wherein the reactive dye was 3.5% by mass compared to 1 gram of fabric; the sample of 1 g of cotton fabric was immersed in the reverse glue with a bath ratio of 1:10. In the reactive dye solution encapsulated by bundles, the containe...

Embodiment 3

[0044] In this embodiment, the nonionic surfactant is polyethylene glycol-12-tridecyl ether, that is, R in the molecular formula 1 for H, R 2 for linear C 13 Alkyl, n is 12. At room temperature, pre-mix 0.018mol of n-octanol and 0.0024mol of non-ionic surfactant in a beaker by stirring, the ratio is 7.5:1, mix and dissolve in 13ml of n-octane to make a reverse glue Beam solution; a certain amount of Levafix Red CA reactive dye is dissolved in a very small amount of water to make 0.5ml of a 3% reactive dye solution by mass percentage, and the reactive dye solution is slowly injected into the reverse micellar solution. After injection, rotate at 1000rpm After vigorously stirring for 5 minutes, the solution was clarified, and the reactive dye solution encapsulated by reverse micelles was obtained, wherein the reactive dye was 1.5% by mass compared to 1 gram of fabric; Immerse in the reactive dye solution encapsulated in reverse micelles, and vibrate the container filled with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com