Production method of hypochlorous acid solution capable of being stably stored

A technology of hypochlorous acid solution and production method, which is applied in the directions of electrolysis components and electrolysis processes, can solve the problems of poor bactericidal effect, high content of hypochlorite, toxic and side effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

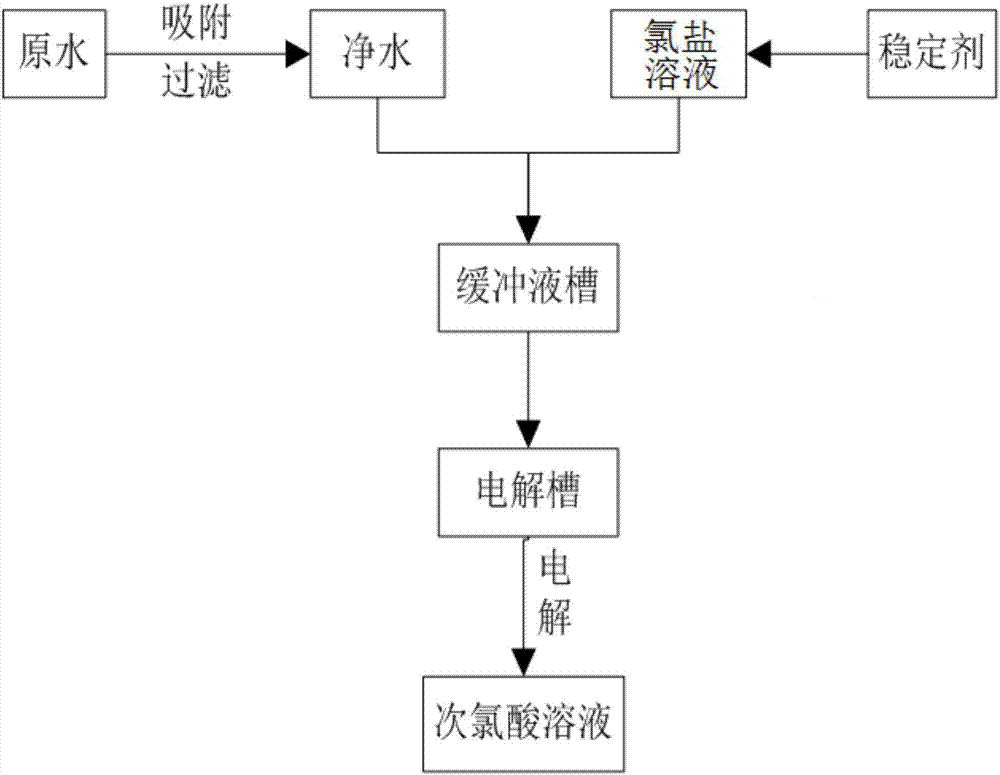

[0022] Such as figure 1 Shown, the step of production method of the present invention is:

[0023] Raw water undergoes activated carbon adsorption filtration, ultrafiltration and reverse osmosis to generate clean water. Add 1-500ppm stabilizer to the chloride salt solution, and control the ratio of raw materials and parameter configuration through the electric valve. The chloride salt solution and clean water are in the buffer tank. After mixing and stirring in the medium, enter the electrolytic cell of the potential water reactor, and generate a hypochlorous acid solution by electrolyzing the chlorine salt solution;

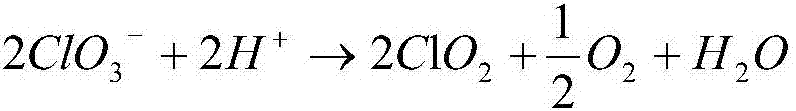

[0024] The hypochlorous acid solution is produced by electrolyzing the chlorine salt solution in the electrolytic cell of the oxidation potential water reactor. Chlorine and oxygen evolution reactions mainly occur at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com