Preparation method for DD5 nickel-base high-temperature alloy powder for 3D printing

A high-temperature alloy and 3D printing technology, which is applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the problems of inability to manufacture, complex internal structure of air-cooled hollow blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

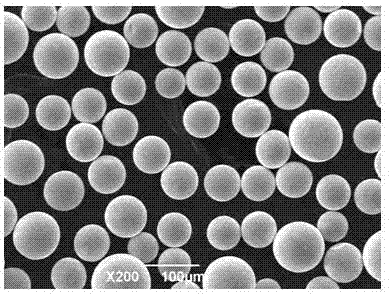

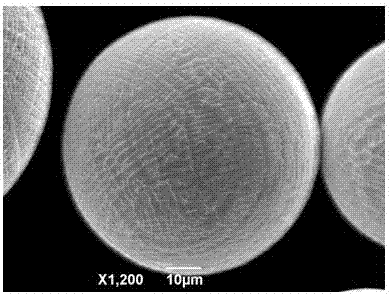

Image

Examples

Embodiment 1

[0019] A preparation method of DD5 nickel-based superalloy powder for 3D printing, comprising the following steps:

[0020] 1) According to mass fraction %: Cr 7.0%, Co 7.5%, W 5.0%, Al 6.2%, Ta 6.5%, Mo 1.5%, Re3.0%, Hf 0.15%, C 0.05%, the balance is Ni The chemical composition is proportioned for batching, vacuum induction melting is used to prepare DD5 master alloy ingots with a diameter of 100mm, and defects such as shrinkage holes in the head are removed;

[0021] 2) Use a high-vacuum heat treatment furnace to homogenize the composition of the DD5 master alloy ingot. The heat treatment process is: heat treatment at 1300 ° C for 24 hours, and then cool to room temperature in the furnace. During the heat treatment, the vacuum degree is -4 Pa;

[0022] 3) The DD5 alloy ingot is finished into an electrode rod with a diameter of 70mm and a length of 400mm, and the roundness deviation is less than 0.05mm, the straightness deviation is less than 0.05mm / m, and the roughness is le...

Embodiment 2

[0028] A preparation method of DD5 nickel-based superalloy powder for 3D printing, comprising the following steps:

[0029] 1) According to mass fraction %: Cr 7.0%, Co 7.5%, W 5.0%, Al 6.2%, Ta 6.5%, Mo 1.5%, Re3.0%, Hf 0.15%, C 0.05%, the balance is Ni The chemical composition is proportioned for batching, vacuum induction melting is used to prepare DD5 master alloy ingots with a diameter of 120mm, and defects such as shrinkage holes in the head are removed;

[0030] 2) Use a high-vacuum heat treatment furnace to homogenize the composition of the DD5 master alloy ingot. The heat treatment process is: heat treatment at 1350°C for 12 hours, cool to room temperature in the furnace, and the vacuum degree during the heat treatment process is -4 Pa;

[0031] 3) The DD5 alloy ingot is finished into an electrode rod with a diameter of 80mm and a length of 800mm, and the roundness deviation is less than 0.05mm, the straightness deviation is less than 0.05mm / m, and the roughness is le...

Embodiment 3

[0037] A preparation method of DD5 nickel-based superalloy powder for 3D printing, comprising the following steps:

[0038] 1) According to mass fraction %: Cr 7.0%, Co 7.5%, W 5.0%, Al 6.2%, Ta 6.5%, Mo 1.5%, Re3.0%, Hf 0.15%, C 0.05%, the balance is Ni The chemical composition is proportioned for batching, vacuum induction melting is used to prepare DD5 master alloy ingots with a diameter > 80mm, and defects such as shrinkage holes in the head are removed;

[0039] 2) Use a high-vacuum heat treatment furnace to homogenize the composition of the DD5 master alloy ingot. The heat treatment process is: 1300-1350 ° C / 12-24 h / furnace cooling to room temperature, and the vacuum degree during the heat treatment is -4 Pa;

[0040] 3) The DD5 alloy ingot is finished into an electrode rod with a diameter of 75mm and a length of 650mm, and the roundness deviation is less than 0.05mm, the straightness deviation is less than 0.05mm / m, and the roughness is less than 1.6μm;

[0041] 4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com