Anticorrosive nanometer metal composite material and production method thereof

A nano-metal and composite material technology, applied in the field of anti-corrosion nano-metal composite materials and its production, can solve the problems of easy corrosion, poor adhesion and fusion, easy oxidation, etc., to achieve strong firmness, good retention, and not easy to corrode Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

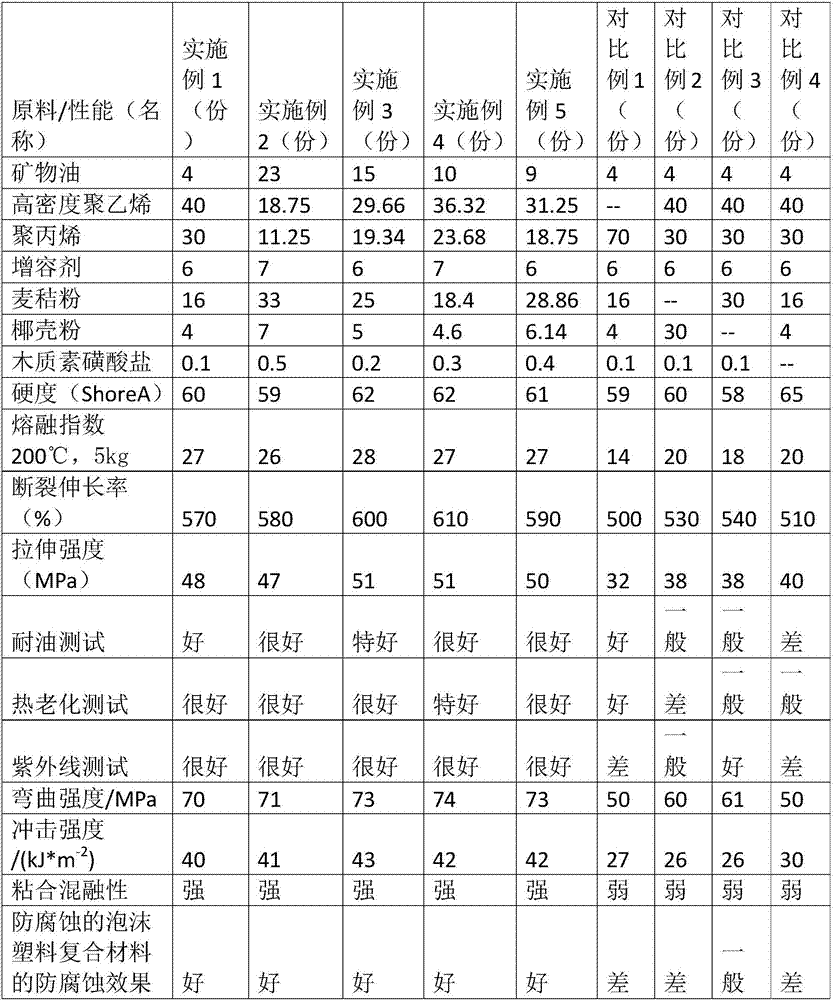

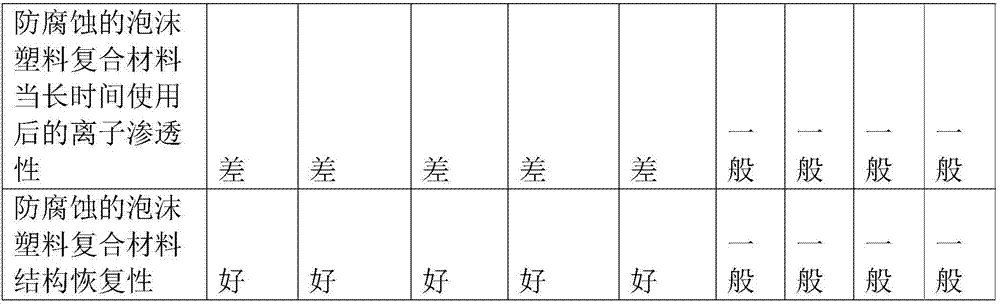

Embodiment 1-5 and comparative example 1-4

[0035] According to the formulas of Examples 1-5 and Comparative Examples 1-2 listed in Table 1 below ("parts" in the table refer to weight fractions, the same below) the wheat straw particles are put into a drying oven and dried at 80°C , when the moisture content of the wheat straw particles is determined to be 7% by a moisture content tester, the drying is stopped, the wheat straw particles are taken out and put into a pulverizer, and crushed to a particle size of 50 mesh to obtain wheat straw powder;

[0036] Put the coconut shell particles into a drying oven and dry them at 120°C. When the moisture content of the coconut shell particles is determined to be 2%, stop drying, take out the coconut shell particles and put them into a pulverizer , be pulverized to particle diameter and be 130 orders, make coconut shell powder;

[0037] After adding mineral oil to high-density polyethylene and polypropylene, put them into the first mixer, mix at 140°C for 10 minutes, then add a ...

Embodiment 6-10

[0047] According to the formula of Examples 6-10 listed in the table below (the "parts" in the table refer to weight fractions, the same below), the wheat straw particles are put into a drying oven and dried at 90°C, and are measured by a moisture content tester. When the moisture content of the wheat straw granules is 10%, stop drying, take out the wheat straw granules and put them into a pulverizer, and pulverize them until the particle diameter is 60 mesh to obtain wheat straw powder;

[0048] Put the coconut shell particles into a drying oven and dry at 150°C. When the moisture content of the coconut shell particles is measured by a moisture content tester at 3%, stop drying, take out the coconut shell particles and put them into a pulverizer , be ground to particle diameter and be 150 orders, make coconut shell powder;

[0049] After adding mineral oil to the high-density polyethylene and polypropylene, put them into the first mixer, mix at 150°C for 20 minutes, then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com