A preparation method of carbon nitride ultrathin sheet with adjustable atomic layer number

A carbon nitride, atomic layer technology, applied in chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., can solve the problems of uncontrollability, long stripping time, low yield, etc. The effect of low cost and fast process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

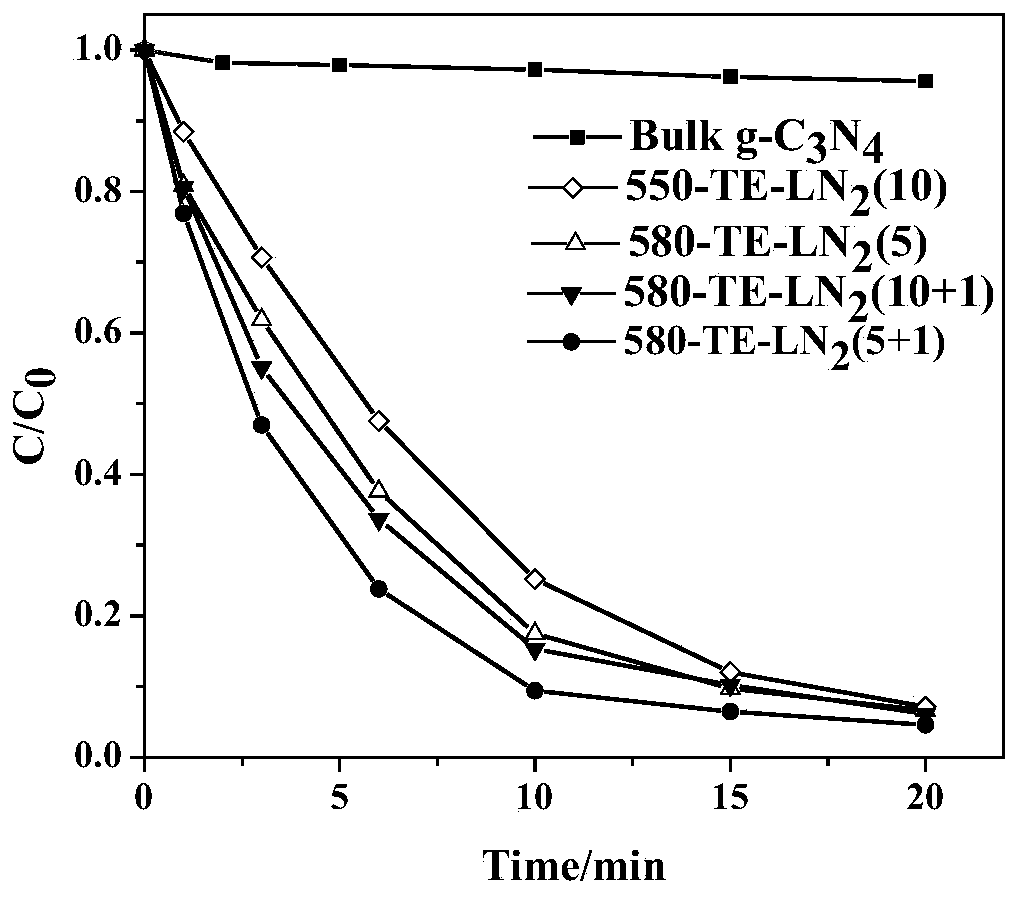

Embodiment 1

[0022] Weigh 3.0g of melamine in a container, put it into a muffle furnace, raise the temperature from room temperature to 550°C in the air, the heating rate is 5°C / min, keep the temperature for 4 hours, and naturally cool to room temperature to obtain yellow Bulk g-C 3 N 4 product.

Embodiment 2

[0024] Weigh 3.0g of dicyandiamide into a container, put it into a muffle furnace, raise the temperature from room temperature to 550°C in the air, the heating rate is 5°C / min, keep the temperature for 4 hours, and naturally cool to room temperature to obtain yellow Bulk g-C 3 N 4 product.

Embodiment 3

[0026] Weigh 6.0g of thiourea into a container, put it into a muffle furnace, and raise the temperature from room temperature to 550°C in the air at a rate of 5°C / min. After constant temperature for 4 hours, cool naturally to room temperature to obtain yellow Bulk g-C 3 N 4 product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com