Bearing column and cantilever device

A technology of a column and a bearing part, which is applied to the field of bearing columns and cantilever devices, can solve the problems of increased horizontal operating force, large hindering effect of the rotating shaft, low operating efficiency, etc., so as to reduce the horizontal operating force, improve the operating efficiency, and reduce the movement obstruction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

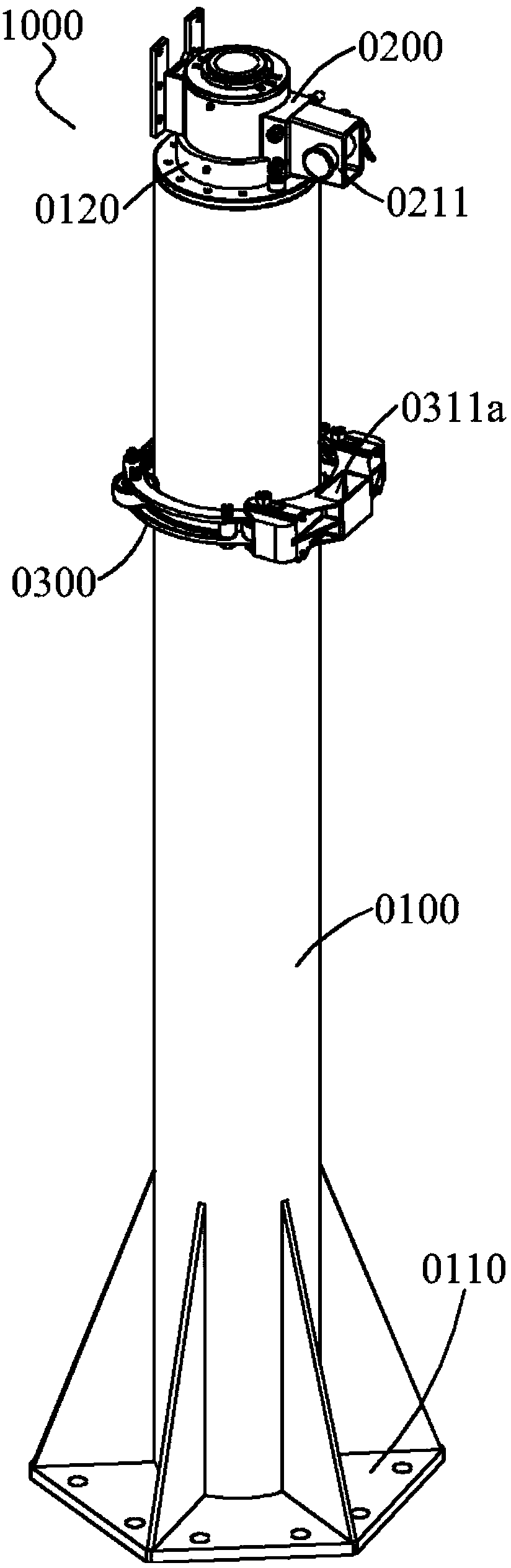

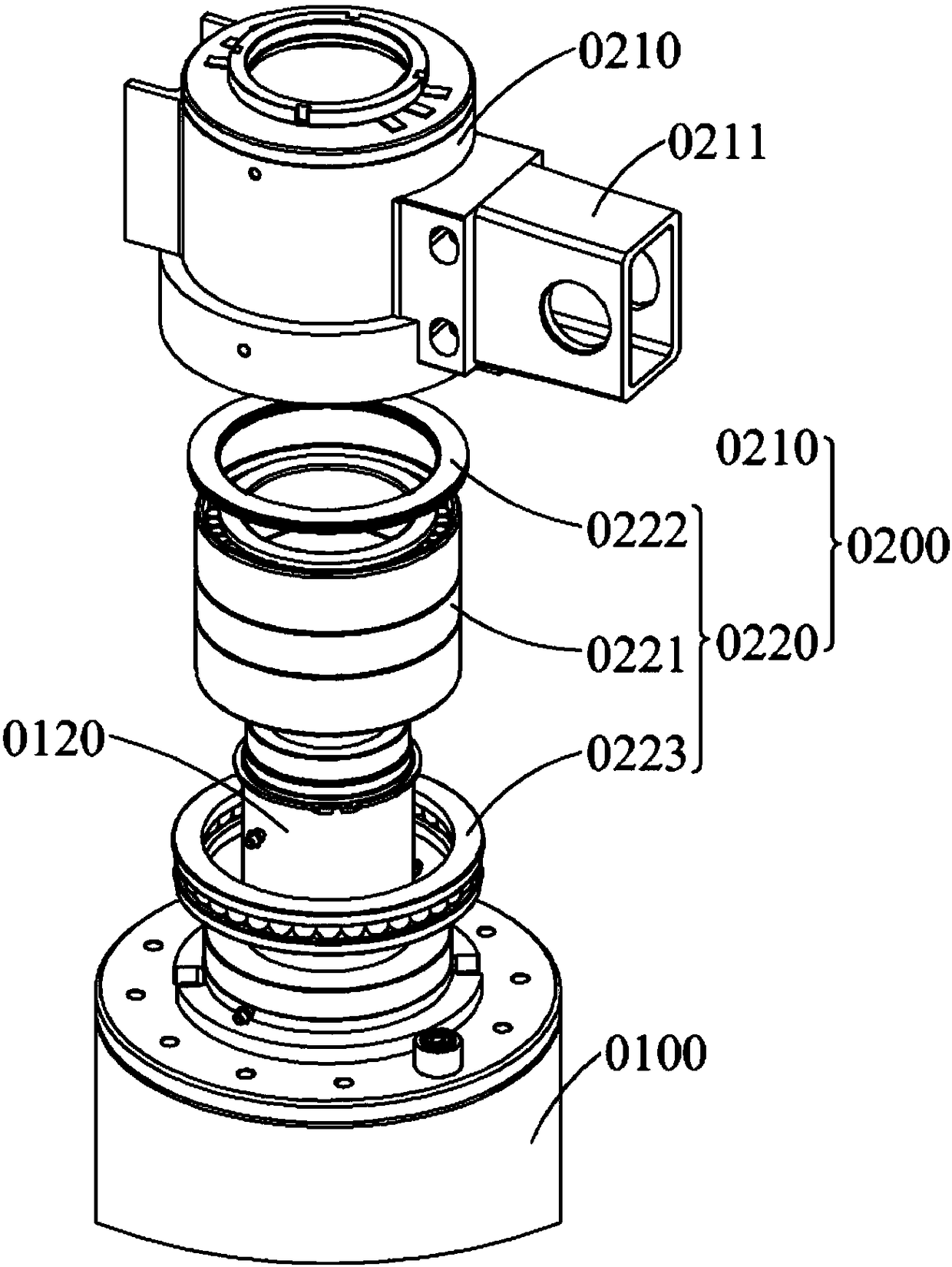

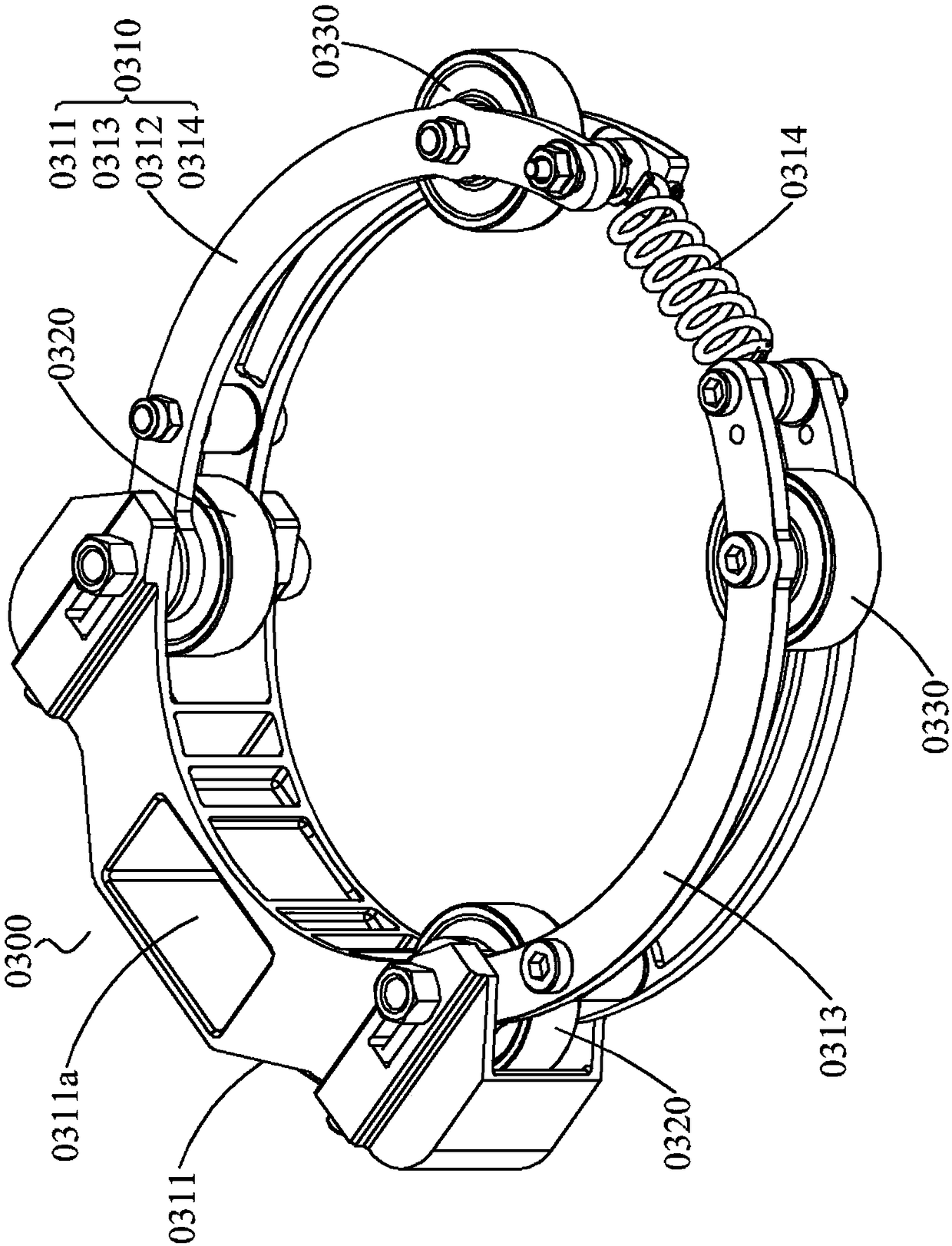

[0040] see figure 1 The supporting column 1000 has a column body 0100, a rotating shaft part 0200 and a bearing part 0300, which can bear the rotational load during the cantilever rotation process, overcome the impact caused by the torque change of the cantilever, and ensure the cantilever to rotate smoothly in the horizontal direction. The specific structure of each part of the supporting column 1000 will be introduced one by one below.

[0041]As a supporting base for supporting the column 1000, the column body 0100 is arranged along the vertical direction. The column body 0100 should have sufficient structural strength and rigidity, and can adopt various structural forms, such as tubular structure, solid column, etc. The column body 0100 can also adopt various shapes, such as square column, cylinder, hexagonal column and so on. The column body 0100 has at least one cylindrical surface between the upper and lower ends, and the central axis of the cylindrical surface coinci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com