Differential cylinder screen for rape combine harvester cleaning

A technology of combine harvester and cylinder sieve, which is applied in application, agricultural machinery and tools, threshing equipment, etc. It can solve the problems of difficult discharge, low speed and low screening efficiency, so as to improve screening efficiency and increase centrifugal force , the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

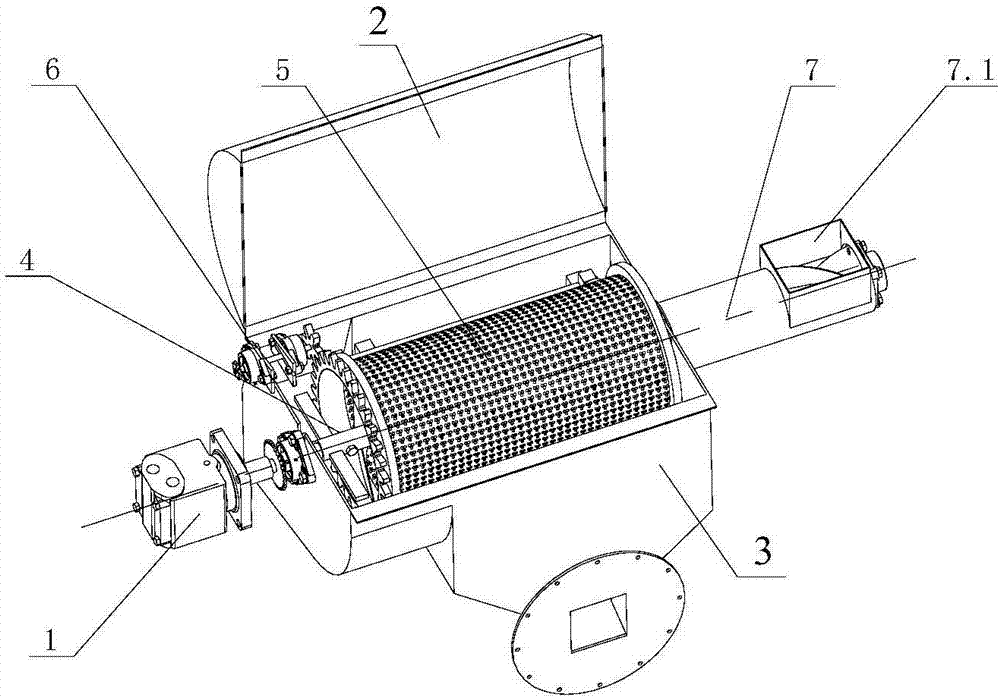

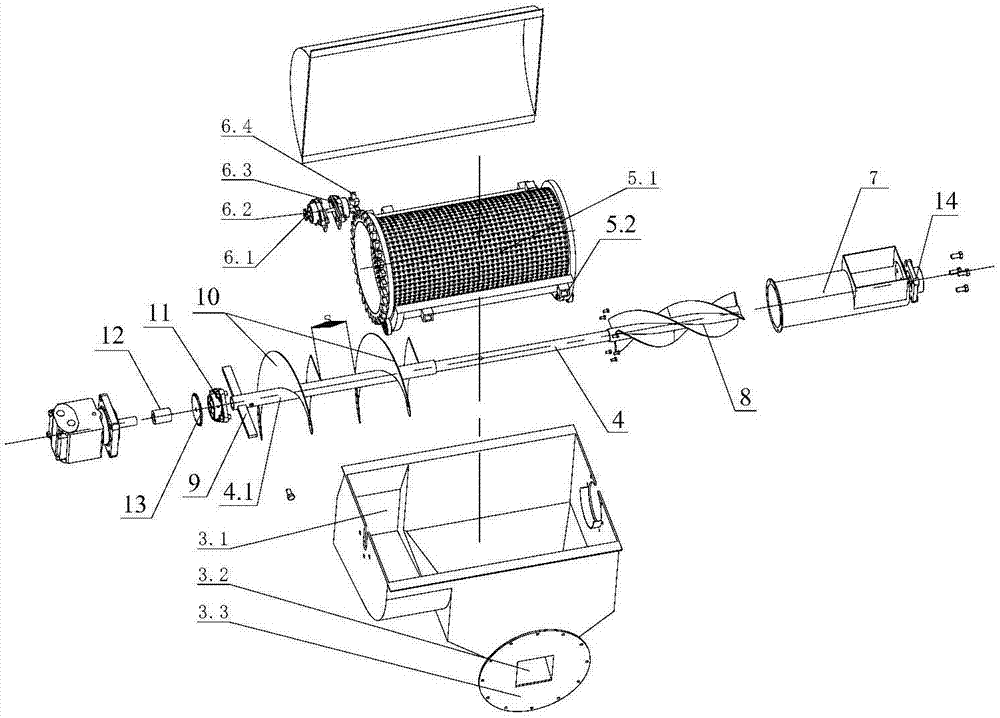

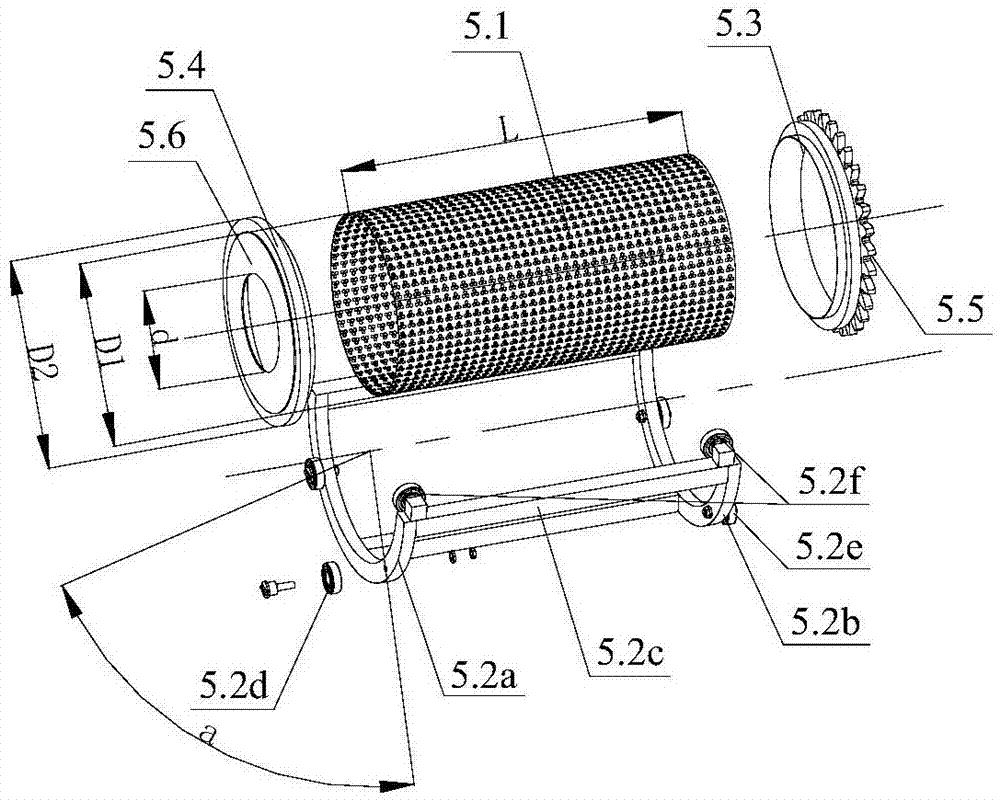

[0020] Such as figure 1 Differential speed drum sieve for oilseed combine harvester cleaning shown, combined with figure 2 As shown, it includes a hollow lower casing 3, an upper casing 2, an intermediate drive train 6 installed on the lower casing 3, and a cylindrical screen installed in a hollow cavity formed by the combination of the lower casing 3 and the upper casing 2. The body 5, the central shaft 4 passing through the cylindrical screen body 5 axially along the center line, and the hydraulic motor 1 connected to the end of the central shaft 4 through a coupling 12 and located outside the lower casing 3, and fixed to the lower casing by bolts The feeding auger shell 7 with the feed port 7.1 on the side plate of the body 3, the grass discharge port 3.1 is opened on the lower shell 3 and located at the position of the grass dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com