A locking device for logistics cargo boxes

A lock device and container technology, applied in the field of warehousing and logistics, can solve the problems of safety accidents, inability to lock the logistics container, and failure to meet the requirements for rapid access and use of the logistics container, so as to save input costs and meet the requirements of access and storage. Use requirements, locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

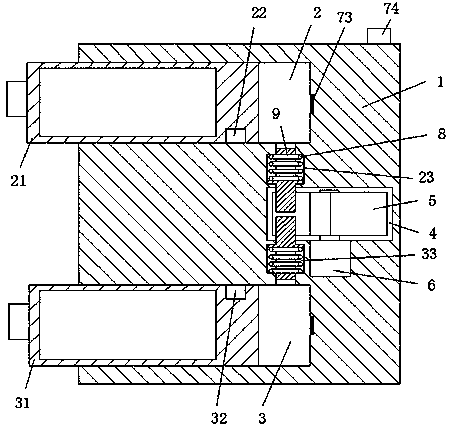

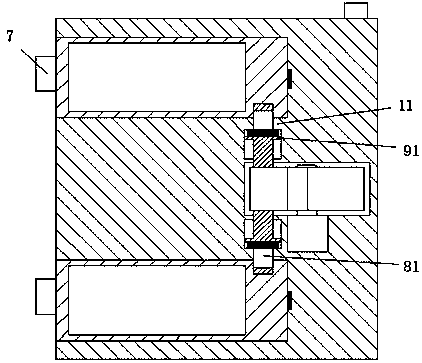

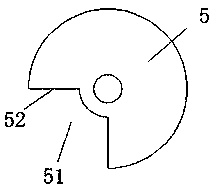

[0018] refer to Figure 1-5 As shown, a locking device for logistics cargo boxes of the present invention includes a frame body 1, and a rear box cavity 2 and a front box cavity 3 arranged in the frame body 1, and are respectively arranged in a sliding manner in the left and right directions. The rear box body 21 and the front box body 31 in the back box cavity 2 and the front box cavity 3, and the rear lock hole 22 that is arranged on the right side front of the rear box body 21, and the front lock that is arranged on the front box body 31 right side rear hole 32, the rear sliding cavity 23 and the front sliding cavity 33 are also provided in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com